Circuit for heating food and food embossing machine applying circuit

A printing machine and food technology, applied in the fields of application, food science, food forming, etc., can solve the problems of short machine life, easy burning of heating tubes, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

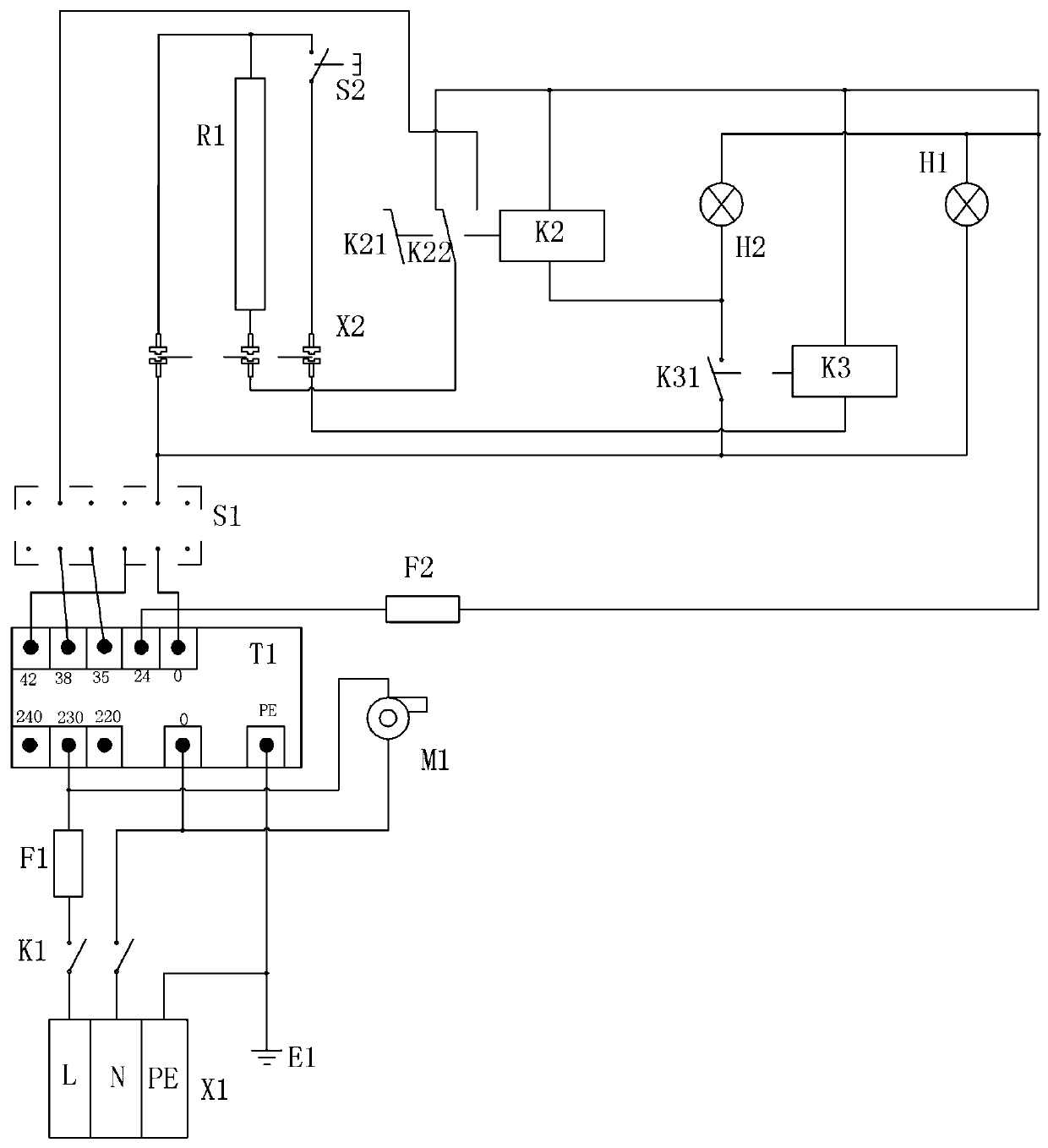

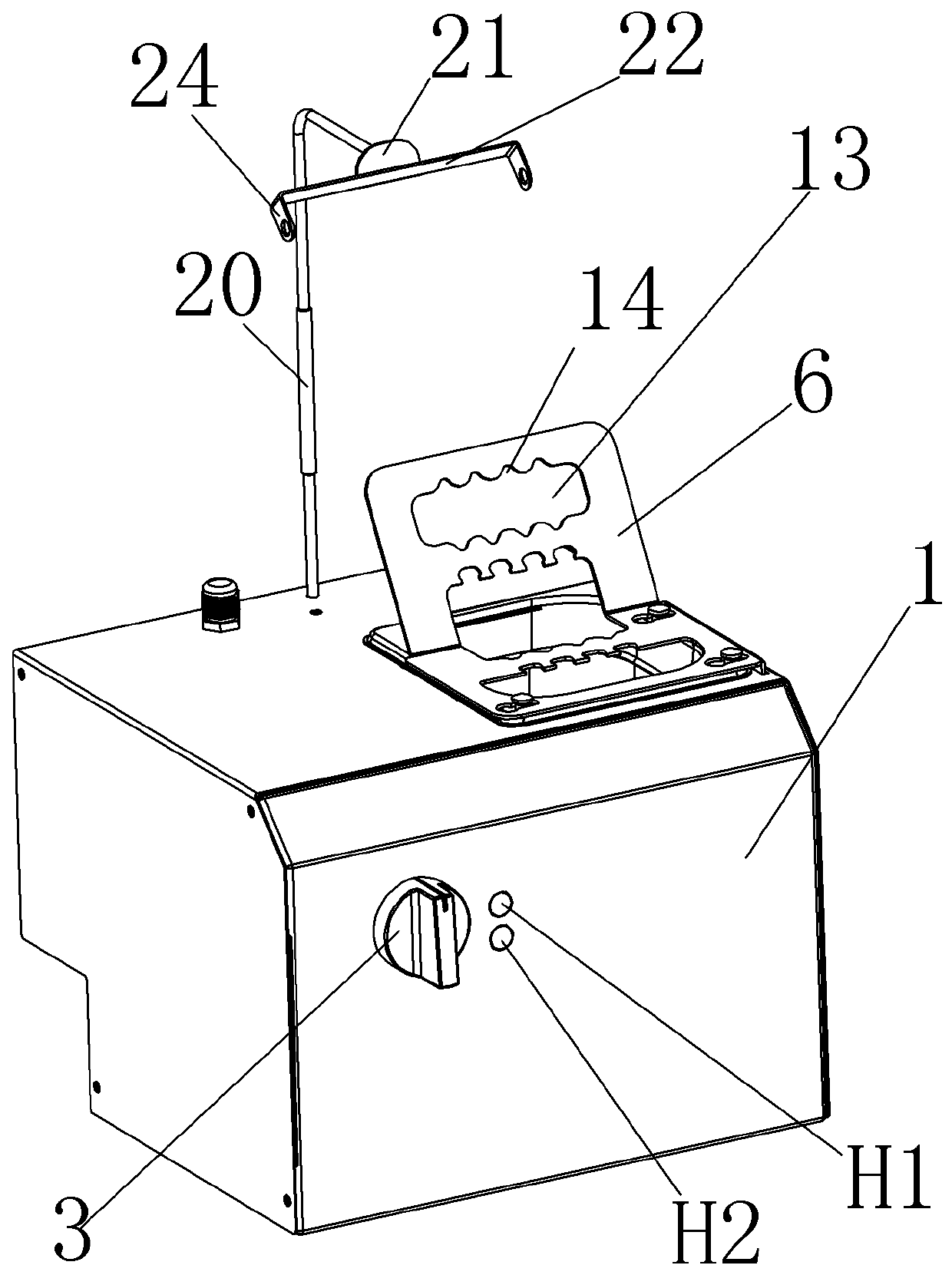

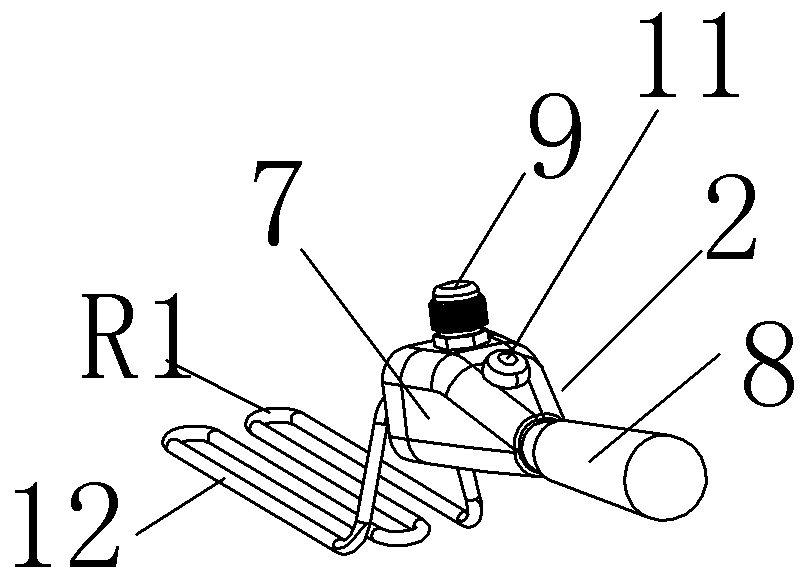

[0021] refer to figure 1 , a circuit for heating food, comprising a heating tube R1 and a transformer T1, the transformer T1 is provided with input terminals of 220V, 230V and 240V, a zero line port and a ground line interface; the output voltages are 24V, 35V, 38V V and 42 V. The 24V output terminal of the transformer is connected with the conversion relay K2 and the delay relay K3, the output terminal of the above transformer is also connected with the heating tube R1 through the normally closed switch K21 of the conversion relay K2, and the other end of the delay relay K3 is connected through the button switch S2 , The gear switch S1 is connected back to the transformer T1, the other end of the conversion relay K2 is connected to the transformer T1 through the switch K31 of the delay relay K3, and the gear switch S1 is connected back to the transformer T1, and the 35 V, 38 V and 42 V output terminals of the transformer pass through the gear The switch S1 and the normally o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com