Nano-dimensional code web printing and feeding device

A technology of feeding device and roll paper, applied in printing device, printing, winding strip, etc., can solve the problems of large fluctuation range of tension force, unrecognizable Nav code, difficult control of motor speed and torque, etc. To achieve the effect of stable tension, simple structure and reliable printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

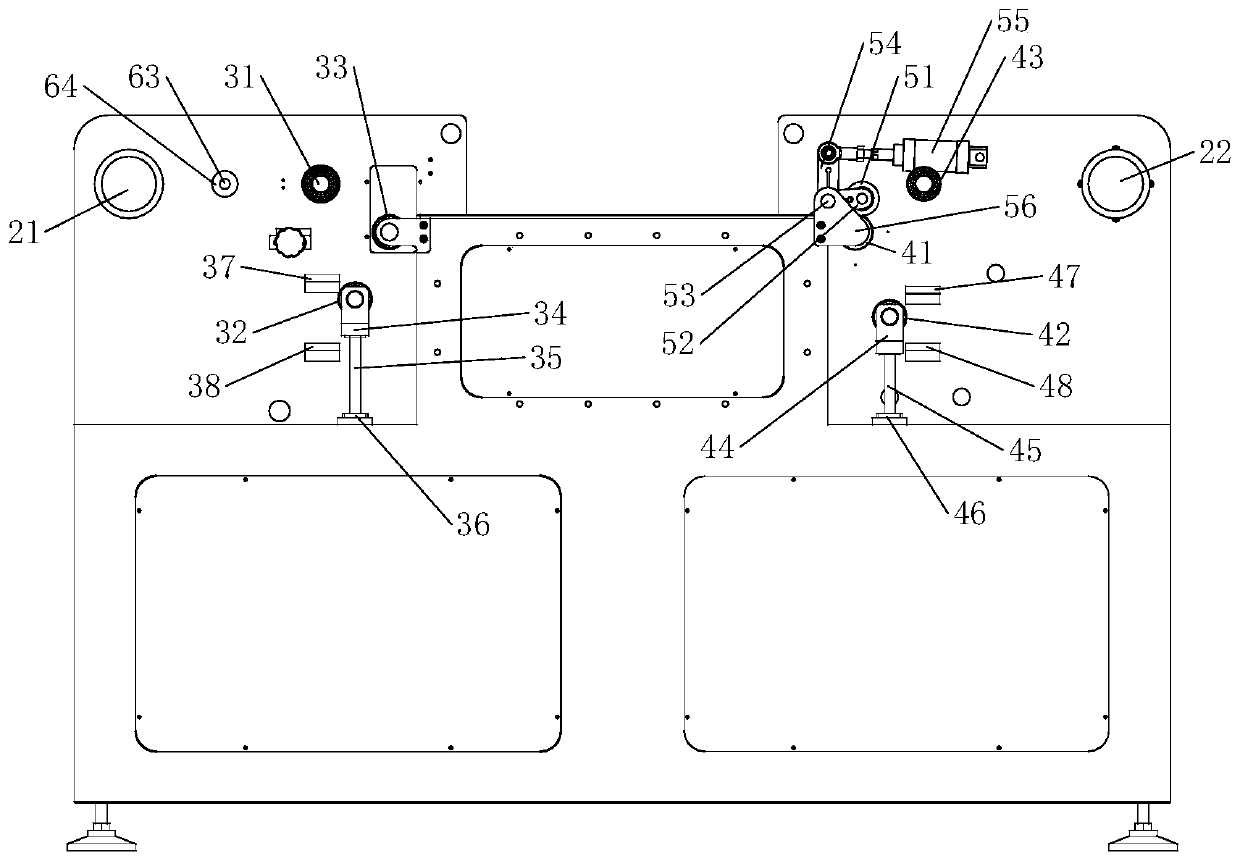

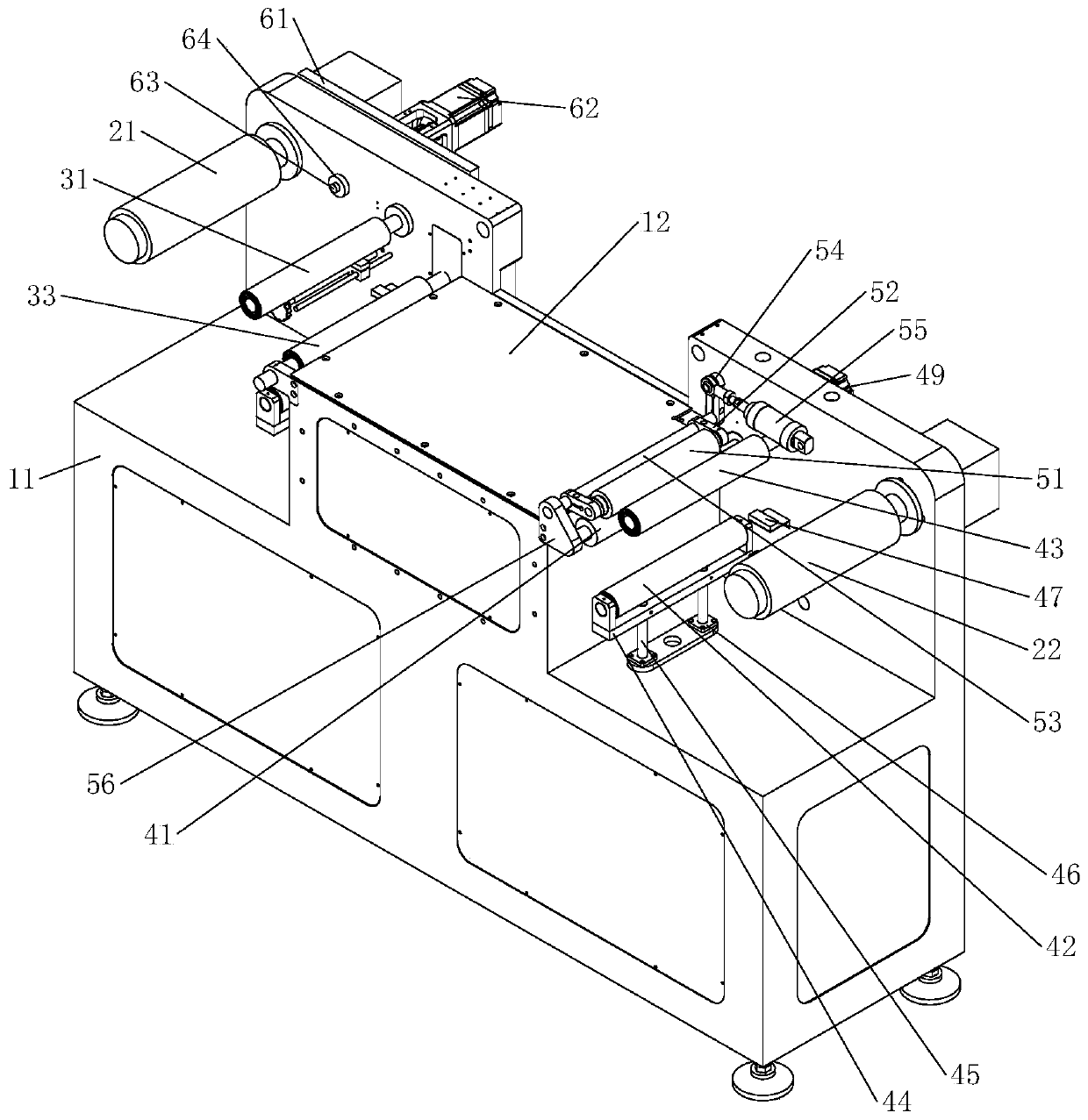

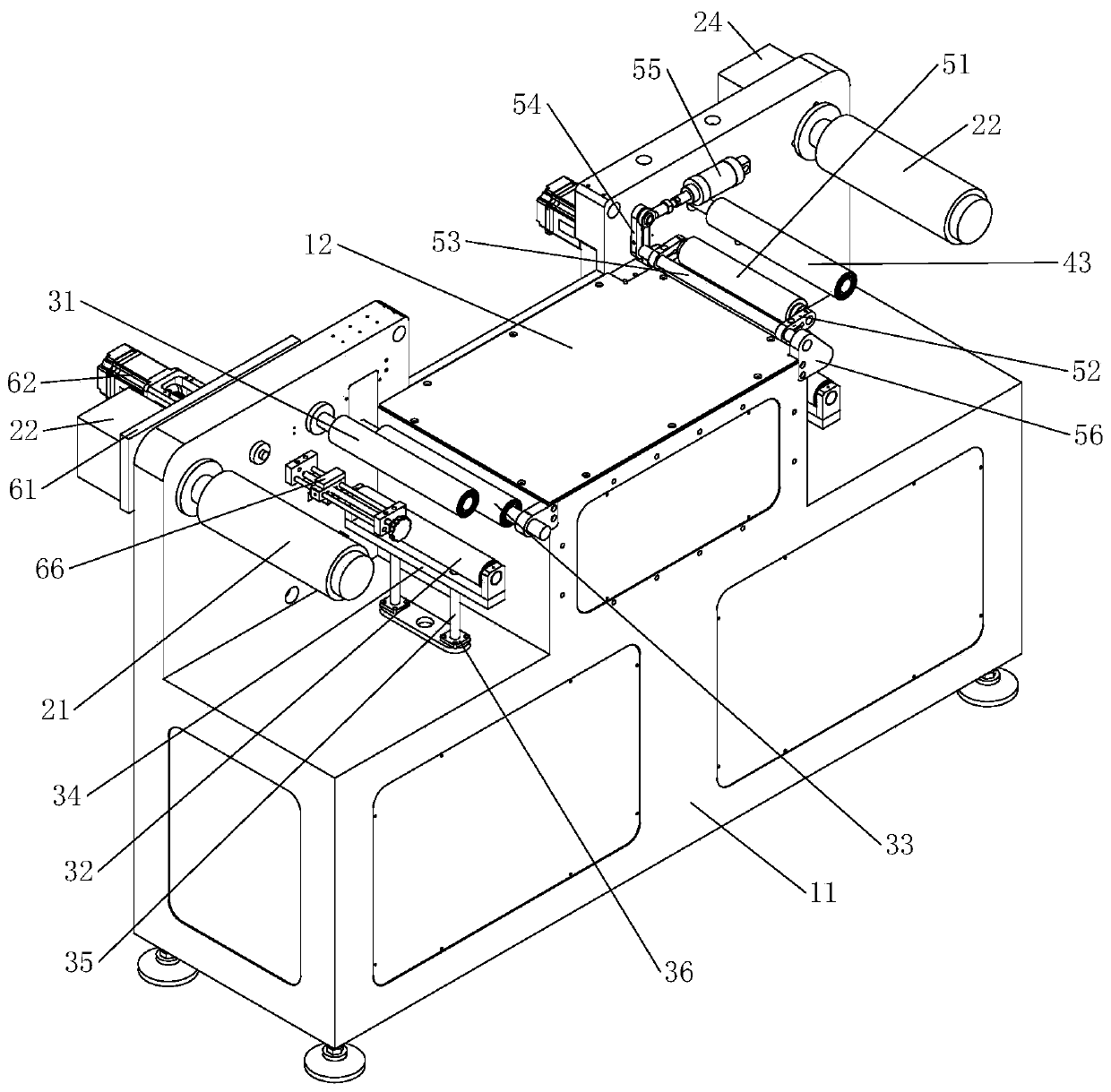

[0034] Such as Figure 1 to Figure 6 As shown, the Navitas roll paper printing and feeding device includes a discharge expansion shaft 21 and a collection expansion shaft 22, and also includes a frame 11 on which a printing platform 12, a discharge expansion shaft 21 and a collection The expansion shafts 22 are installed on the frame 11 and are respectively located on both sides of the printing platform 12; the discharge motor 22, the discharge motor 22 is fixed on the frame 11, and the discharge motor 22 is connected to one end of the discharge expansion shaft 21 Rewinding motor 24, the rewinding motor 24 is fixed on the frame 11, and one end of the rewinding expansion shaft 22 is connected to the rewinding motor 24; and the printing tensioning device, which is installed on one side of the printing platform 12, And it is located between the printing platform 12 and the discharging expansion shaft 21.

[0035] The unwinding expansion shaft 21 and the receiving expansion shaft 22...

Embodiment 2

[0054] On the basis of the above-mentioned embodiment, it also includes a winding tensioning device. The winding tensioning device is located on the other side of the printing platform 12. The winding tensioning device includes a winding tensioning active roller 41. One end of 41 is installed on the frame 11 and located on the other side of the printing platform 12; the winding tension motor 49, the winding tension motor 49 is fixed on the frame 11, and is connected to the winding tension driving roller 41 One end is connected; the pressing roller 51, the pressing roller 51 is located above the winding and tensioning active roller 41; the pressing device, the pressing device is fixed on the frame 11, the pressing device is equipped with a pressing roller 51, the pressing device It is used to press the pressure roller 51 on the winding tension driving roller 41; the winding tension roller 42, which is located below the winding tension driving roller 41; the winding tension seat 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com