Water-permeable concrete formula and preparation method thereof

A concrete and formula technology, applied in the field of permeable concrete formula and its preparation, can solve the problems of cement and lime mixed into fine pores, low mechanical strength, etc., and achieve the effects of reducing corrosion, improving water permeability and mechanical function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

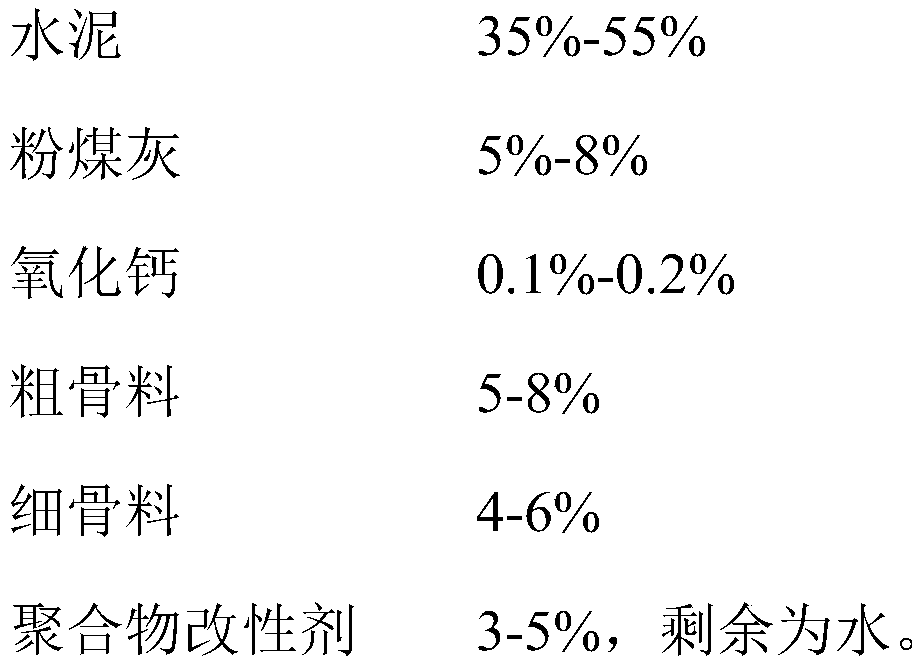

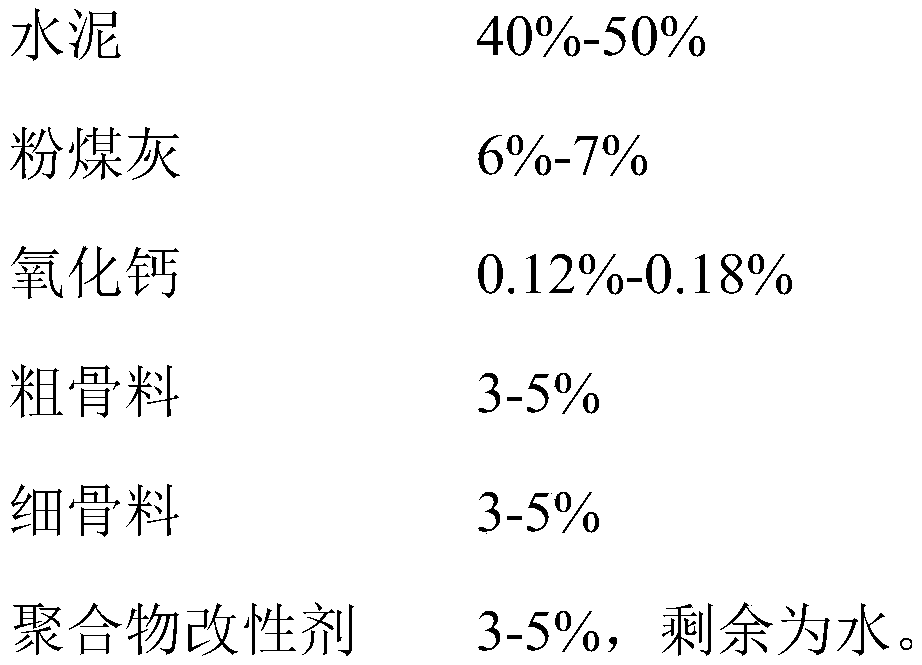

Method used

Image

Examples

Embodiment 1

[0021] The marble is crushed into gravel with a particle size of 4-8mm and 15-24mm by a double-cavity jaw crusher, and the crushed stone with a particle size of 4-8mm is directly used as fine aggregate, and the particle size is 15-24mm. Spherical or ellipsoid with smooth surface, as fine aggregate; the bulk density of the fine aggregate is 1481kg / m 3 , the porosity is 43%; the bulk density of the coarse aggregate is 1089kg / m 3 , the porosity is 56%;

[0022] Fly ash is waste from power plants, the particle size is 10-20μm, and the bulk density is 190kg / m 3 . The specific surface area is 19.0m 2 / g, silica content ≥ 90%.

[0023] Mix 5kg of coarse aggregate and 4kg of fine aggregate evenly, spray 9L of water, stir at a rate of 20r / min, and stir for 1-3min to ensure that the surface of the coarse aggregate and fine aggregate is covered with water; add 7kg of cement and 1kg of Coal ash, the stirring rate is 20r / min, and the stirring time is 2-5min, until the surface of coars...

Embodiment 2

[0025] The marble is crushed into gravel with a particle size of 4-8mm and 15-24mm by a double-cavity jaw crusher, and the crushed stone with a particle size of 4-8mm is directly used as fine aggregate, and the particle size is 15-24mm. Spherical or ellipsoid with smooth surface, as fine aggregate; the bulk density of the fine aggregate is 1480kg / m 3 , the porosity is 43%; the bulk density of the coarse aggregate is 1060kg / m 3 , the porosity is 55%;

[0026] Fly ash is waste from power plants, the particle size is 10-20μm, and the bulk density is 210kg / m 3 , the specific surface area is 18.5-19.5m 2 / g, silica content ≥ 90%.

[0027] Mix 8kg of coarse aggregate and 6kg of fine aggregate evenly, spray 12L of water, stir at a rate of 20r / min, and stir for 1-3min to ensure that the surface of the coarse aggregate and fine aggregate is covered with water; add 11kg of cement and 1.6 kg of coal ash, the stirring rate is 20r / min, and the stirring time is 2-5min, until the surface...

Embodiment 3

[0029] The marble is crushed into gravel with a particle size of 4-8mm and 15-24mm by a double-cavity jaw crusher, and the crushed stone with a particle size of 4-8mm is directly used as fine aggregate, and the particle size is 15-24mm. Spherical or ellipsoid with smooth surface, as fine aggregate; the bulk density of the fine aggregate is 1456kg / m 3 , the porosity is 41%; the bulk density of the coarse aggregate is 1030kg / m 3 , with a porosity of 56%

[0030] Fly ash is waste from power plants, the particle size is 10-20μm, and the bulk density is 220kg / m 3 , the specific surface area is 18.5-19.5m 2 / g, silica content ≥ 90%.

[0031] Mix 6kg of coarse aggregate and 5kg of fine aggregate evenly, spray 10L of water, the stirring speed is 20r / min, and the stirring time is 1-3min, to ensure that the surface of coarse aggregate and fine aggregate is covered with water; add 8kg of cement and 1.2 kg of coal ash, the stirring rate is 20r / min, and the stirring time is 2-5min, unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap