Vertical column pressure self-adaptive adjusting and controlling system

A self-adaptive regulation and column technology, applied in the direction of pillars/brackets, mining equipment, earthwork drilling and mining, etc., can solve the problems of reducing the initial support force of the support, the pressure of the advanced support does not have the ability of self-adaptive adjustment, and it is difficult to match in real time. achieve an easy-to-achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

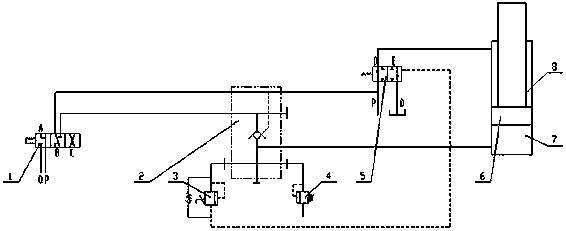

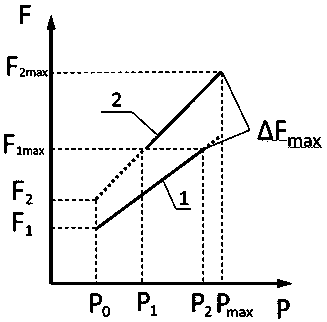

[0023] Such as figure 1 As shown in Fig. 1 , a column pressure self-adaptive control system is mainly used for the support resistance control of the advanced hydraulic support in the roadway of the working face, including the reversing valve (1), the hydraulic control check valve (2), the sequence valve (3), the safety Valve (4), hydraulic reversing valve (5), column (6), column lower cavity (7), column upper cavity (8), liquid supply pipeline P and liquid return pipeline O; The direction valve (1) is in position A, the lower chamber of the column (7) and the upper chamber of the column (8) are connected with the liquid supply pipeline P, and the initial support force of the column is the ring of the lower chamber of the column (7) and the upper chamber of the column (8). The cavity area difference is multiplied by the liquid supply pressure of the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com