Driving type water-drop-form two-side synchronous rotating mechanism

A technology of synchronous rotation and synchronous mechanism, which is applied in the direction of mechanical equipment, transmission devices, friction transmission devices, etc., and can solve the problem of high requirements for internal bending mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

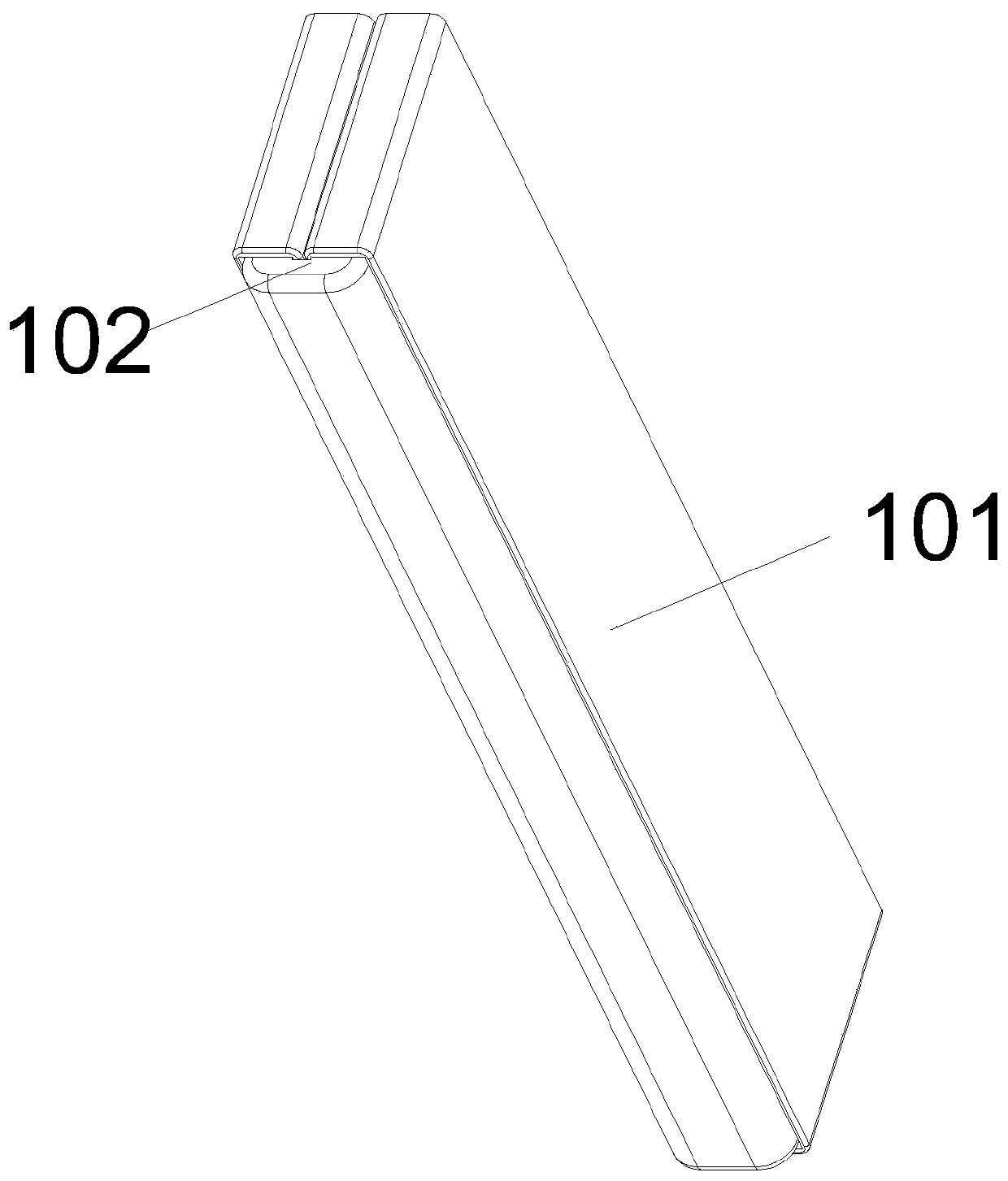

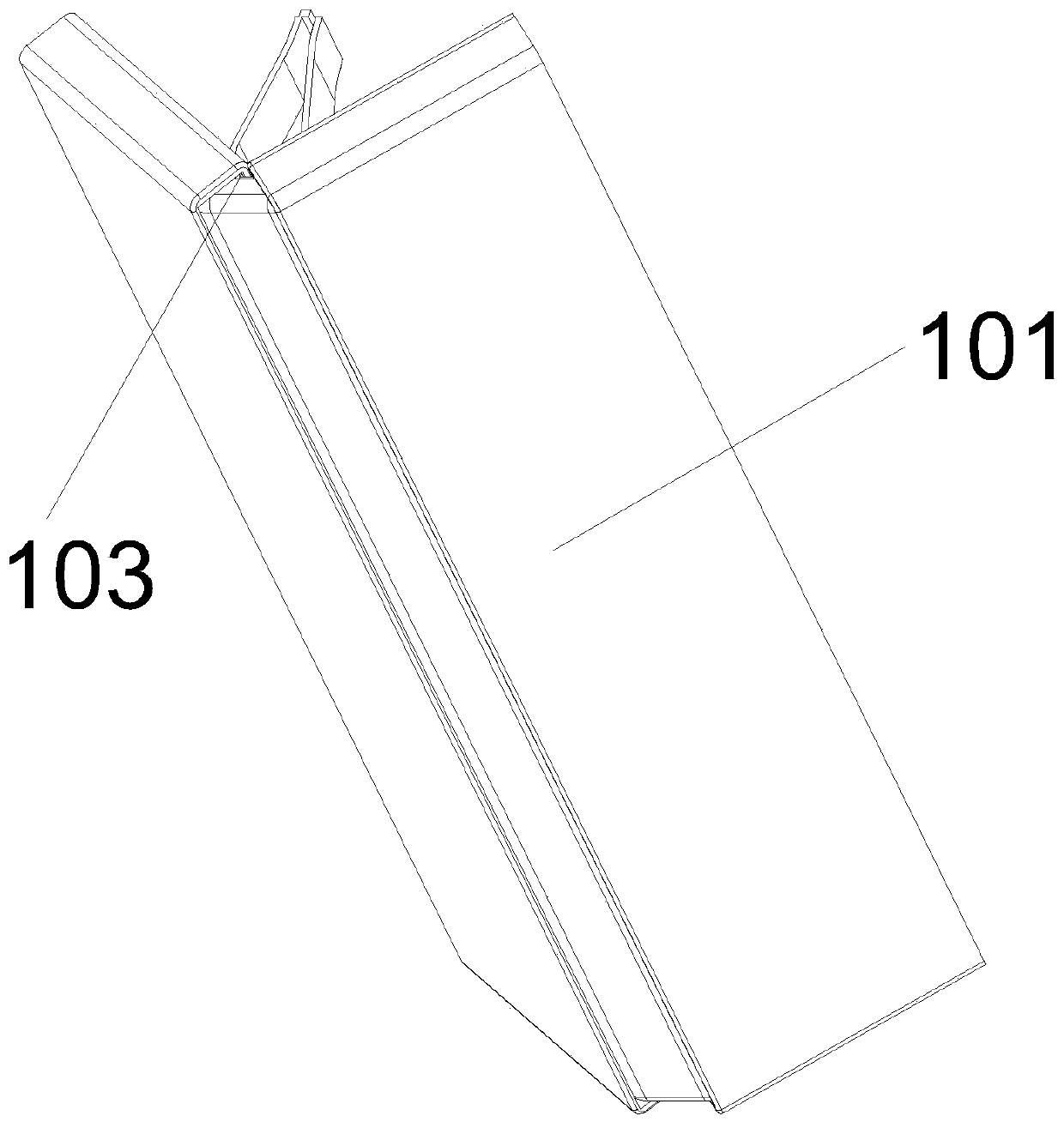

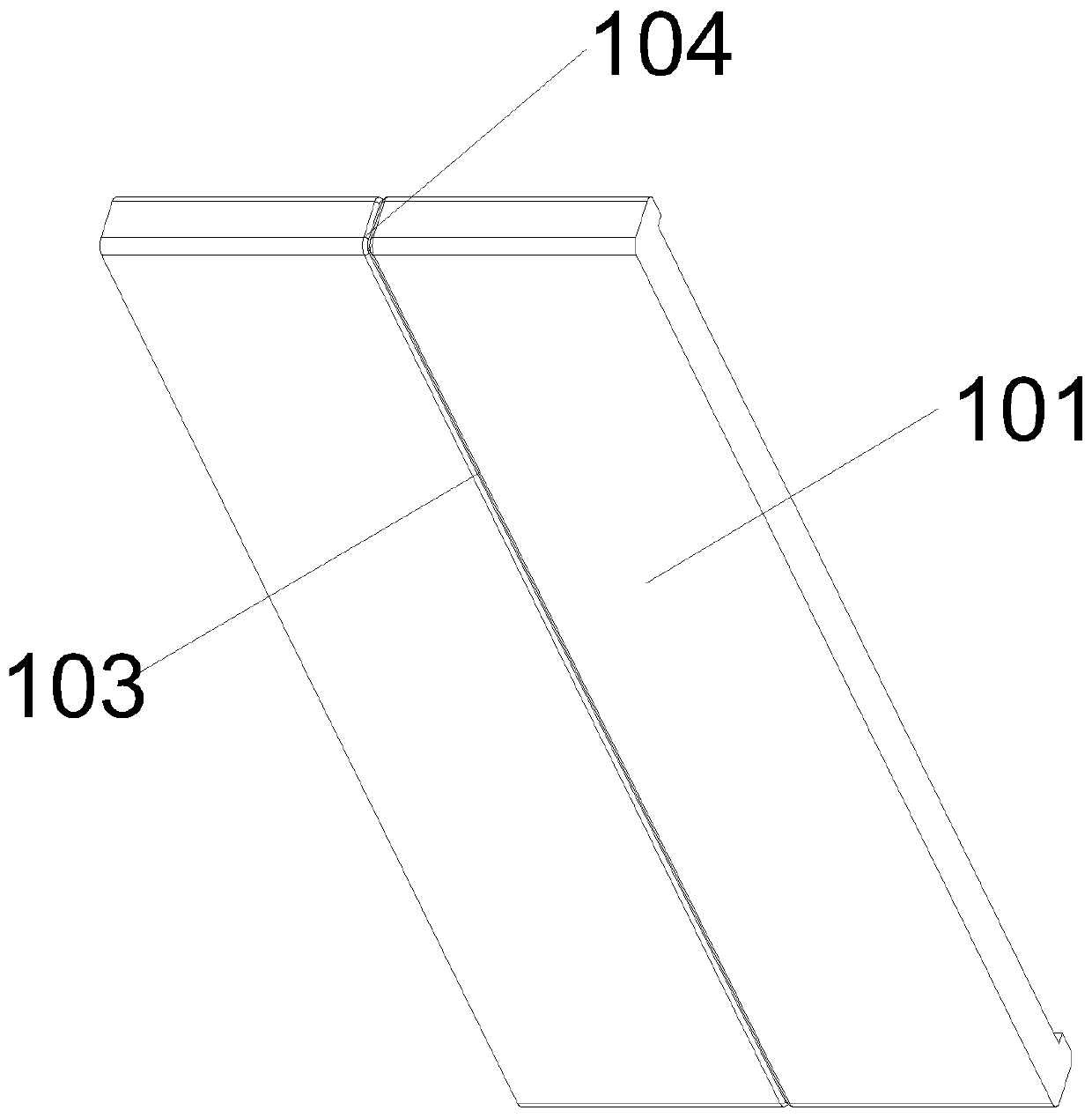

[0105] Such as Figure 1-15 As shown, the active water drop-shaped synchronous rotation mechanism on both sides disclosed in this embodiment includes a structural main body 101. The structural main body 101 is composed of a synchronous mechanism 102, an active steering mechanism 103 and an auxiliary mechanism 104. The synchronous mechanism 102 includes gears 21 and the rack 2, the active steering mechanism 103 includes a shaft cover 6 and multiple sets of movable blocks, and the auxiliary mechanism 104 includes a U spring 5 for realizing torsion and screen locking; the structure of the movable block is set as follows:

[0106] One of the movable blocks is provided with a combination of a chute 105 and a nail 106, a combination of a fixed tooth 107 and a positioning rack 108 to realize the displacement required for bending;

[0107] One of the movable blocks is provided with an internal arc 109 combined with the movable plate nail 301, the movable plate chute 110 combined with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com