Radio-frequency rotary joint and ion etching system therewith

An ion etching and rotary joint technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve problems such as the inability to meet the requirements of substrate rotation, and achieve the effects of various connection methods, improved speed and uniformity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

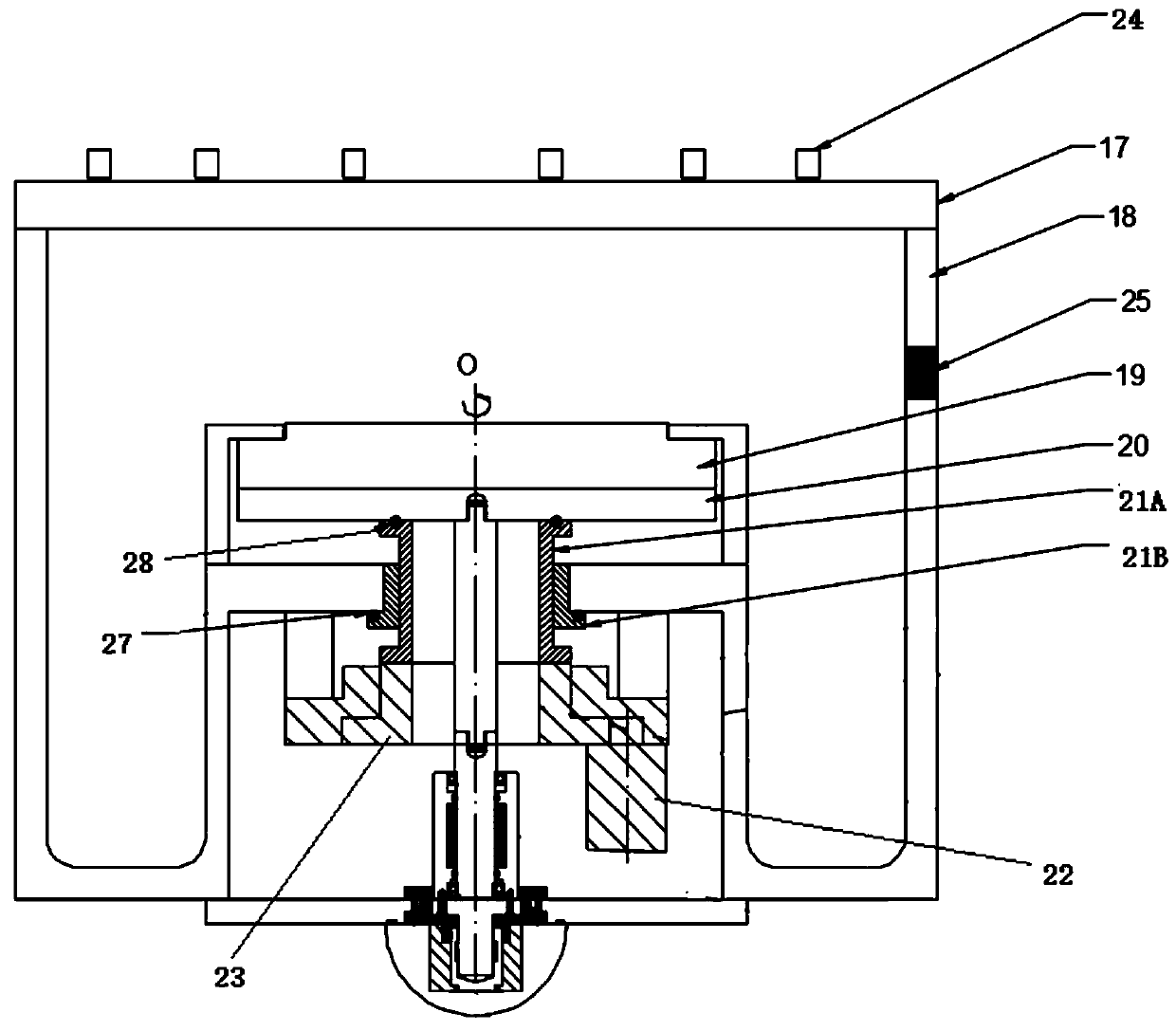

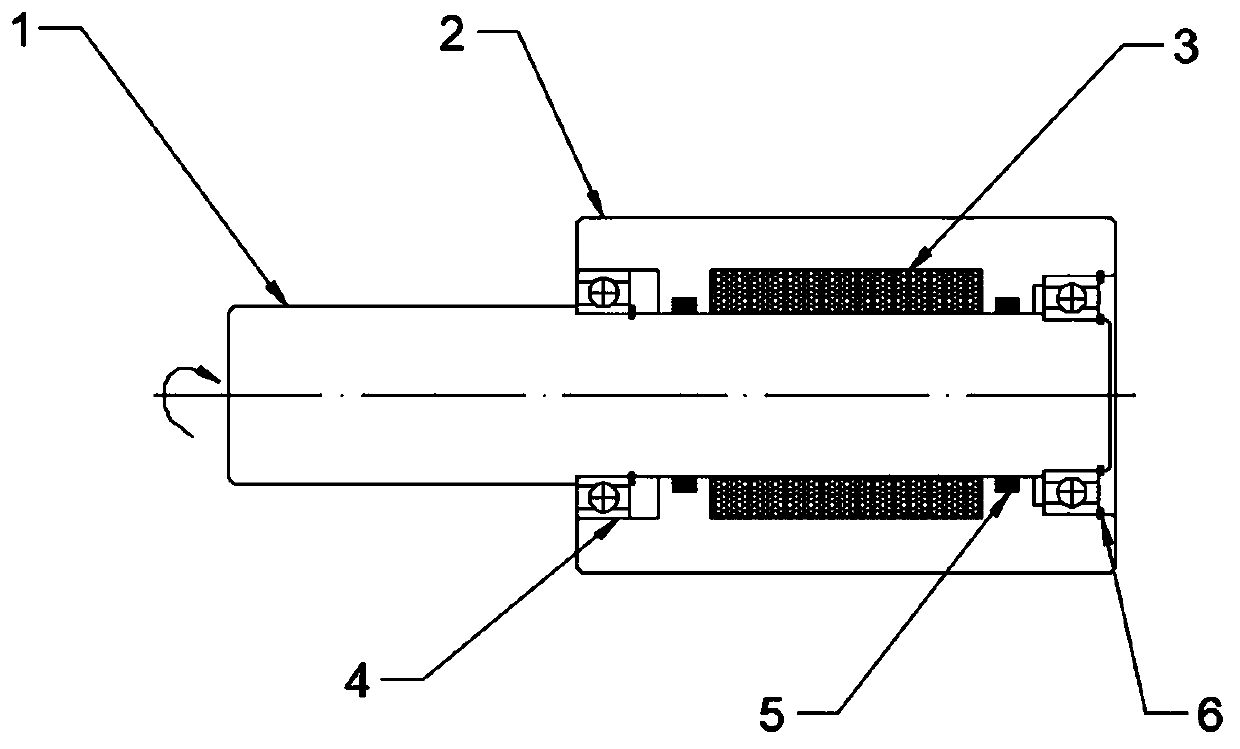

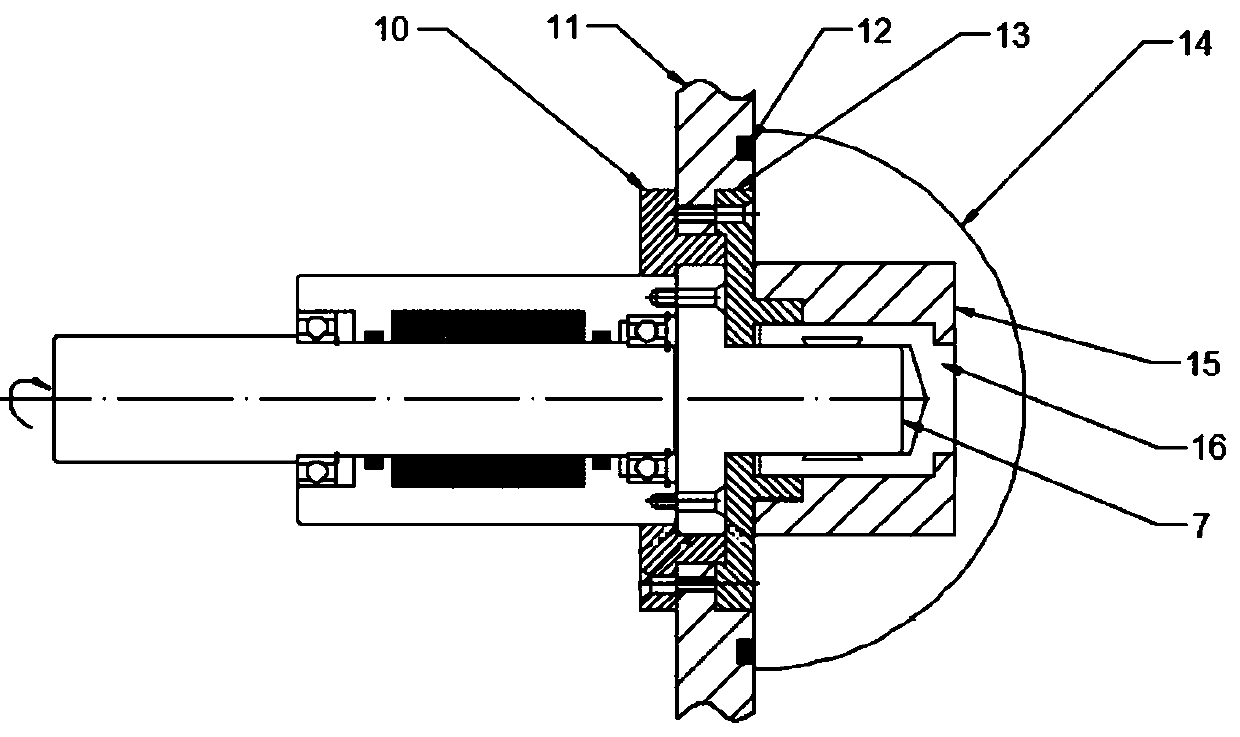

[0032] like figure 2 , the present invention proposes a radio frequency rotary joint for an ion etching system, including a radio frequency rotor 1 for accessing a bias electrode 19 and a radio frequency stator 2 for accessing a radio frequency current, and the radio frequency stator 2 is provided with Rotating hole; the radio frequency rotor 1 can be rotatably placed in the rotating hole; a conductive jacket 3 made of spherical metal particles is embedded between the inner wall of the rotating hole and the outer wall of the radio frequency rotor 1, and the spherical metal particles preferably adopt the conductivity coefficient Excellent copper.

[0033] The spherical metal particles of the conductive jacket 3 are closely arranged one by one, so the conductive jacket 3 enables the RF rotor 1 to rotate smoothly in the rotating hole of the RF stator 2, and at the same time makes the gap between the RF rotor 1 and the RF stator 2 rotate Maintain reliable electrical contact, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com