One-way sliding type spherical steel supporting seat

A one-way sliding, spherical steel technology, used in bridge parts, bridges, buildings, etc., can solve the problems of not being able to meet special bridges, only short-distance displacement, and the transmission spherical bearing can only rotate, so as to meet the bridge displacement requirements. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

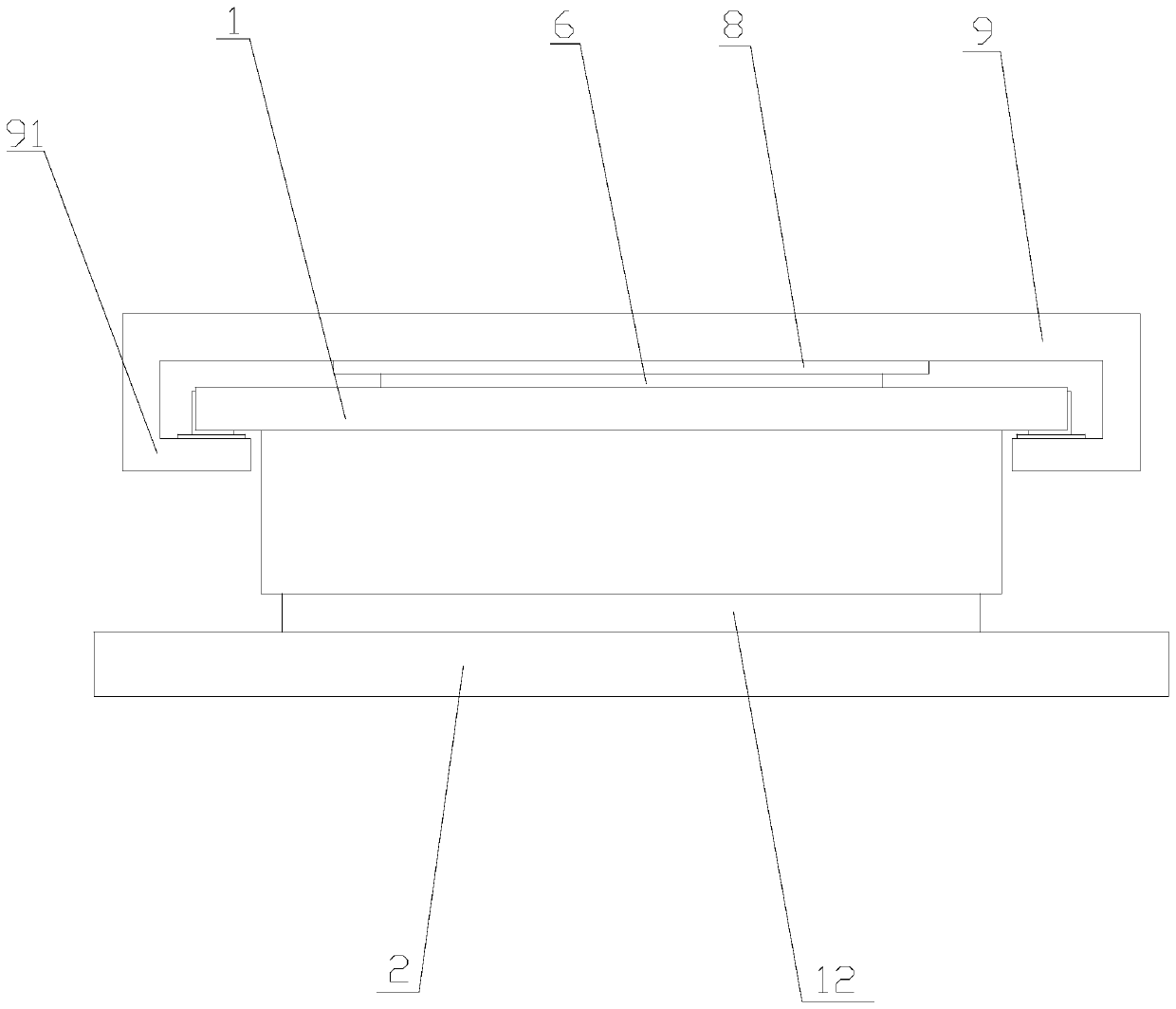

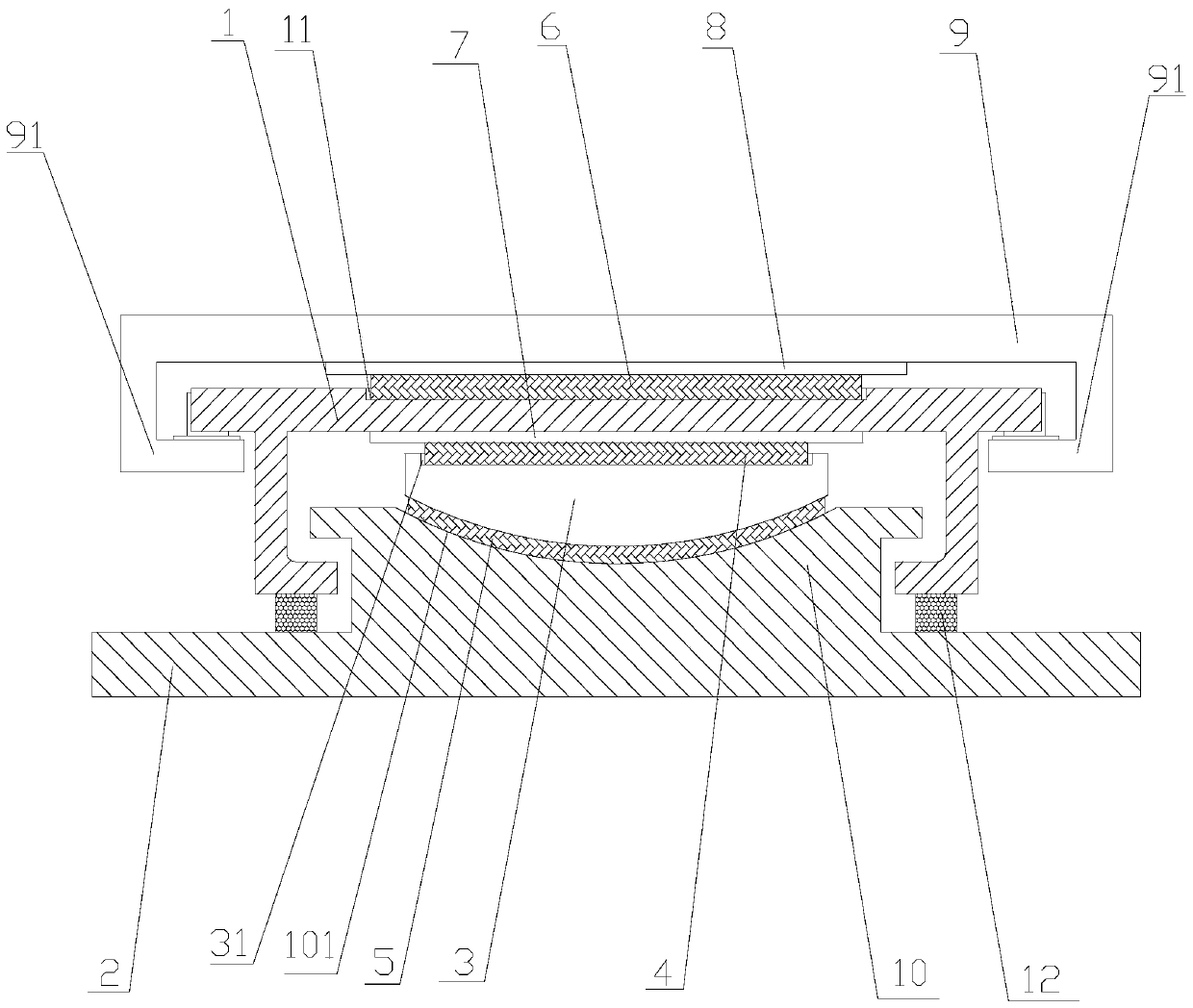

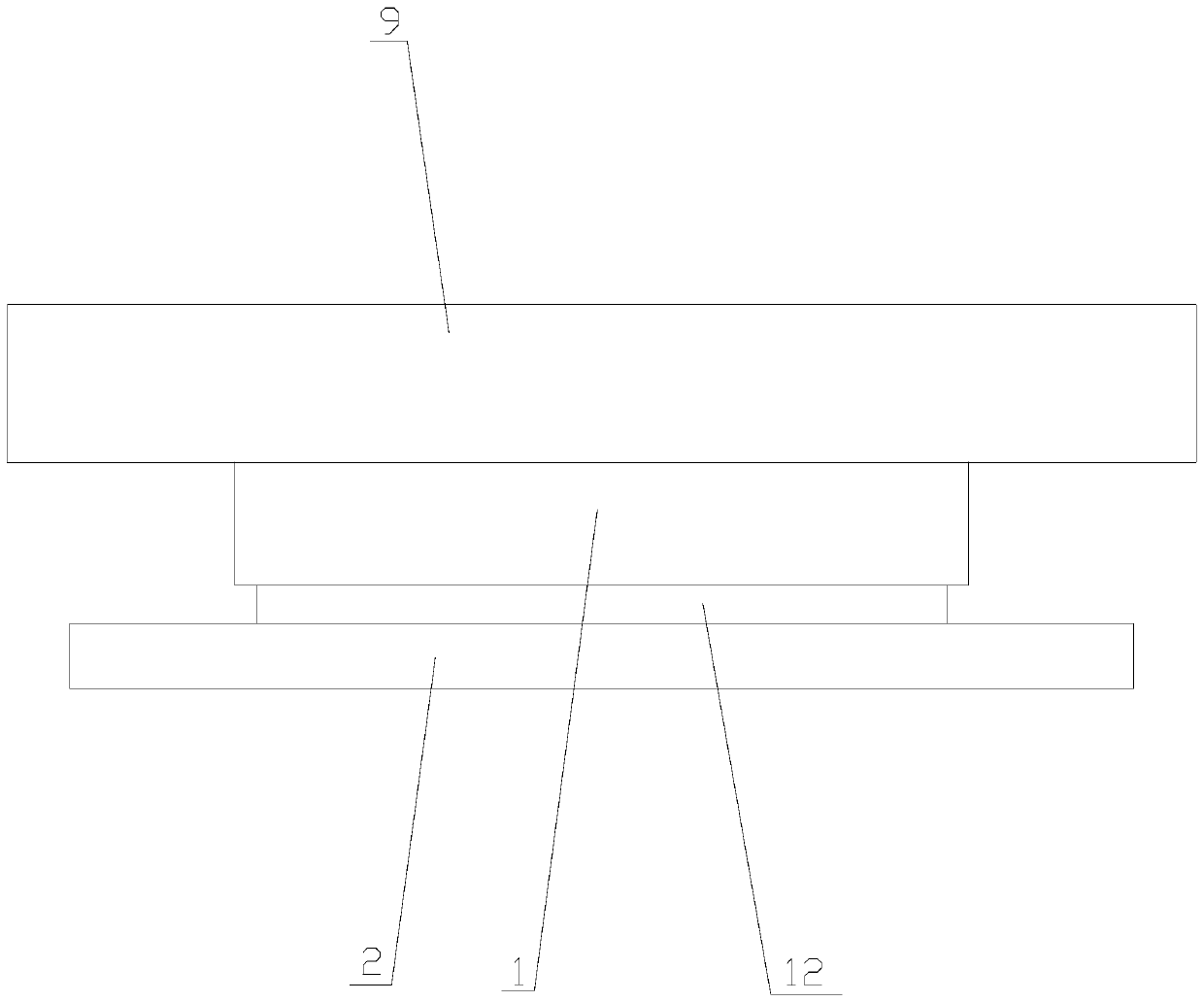

[0019] refer to figure 1 , figure 2 and image 3 , a one-way sliding spherical steel bearing of the present invention, comprising a bearing top plate 1, a bearing bottom plate 2, a spherical crown liner 3, a first plane PTFE slide 4, a spherical PTFE slide 5, a second plane PTFE Sliding plate 6, the first stainless steel plate 7, the second stainless steel plate 8, upper sliding plate 9, intermediate seat body 10, the upper end of described support bottom plate 2 is provided with intermediate seat body 10, and the upper end of described intermediate seat body 10 is provided with can The spherical crown groove 101 that cooperates with the spherical crown liner 3, the lower spherical surface of the spherical crown liner 3 is arranged in the spherical crown groove 101, and the spherical crown liner 3 and the spherical crown groove 101 are provided There is a spherical PTFE slide plate 5, and the upper end of the spherical crown liner 3 is provided with a first plane PTFE slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com