Silk screen groove roller rolling forming press

A grooved roller and sub-roller technology, which is applied to the field of wire mesh grooved roller rolling and pressing machines, can solve the problems of easy breakage of wire mesh weaving and increased hole mesh, and achieve the effect of avoiding the increase of hole mesh and avoiding pulling damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

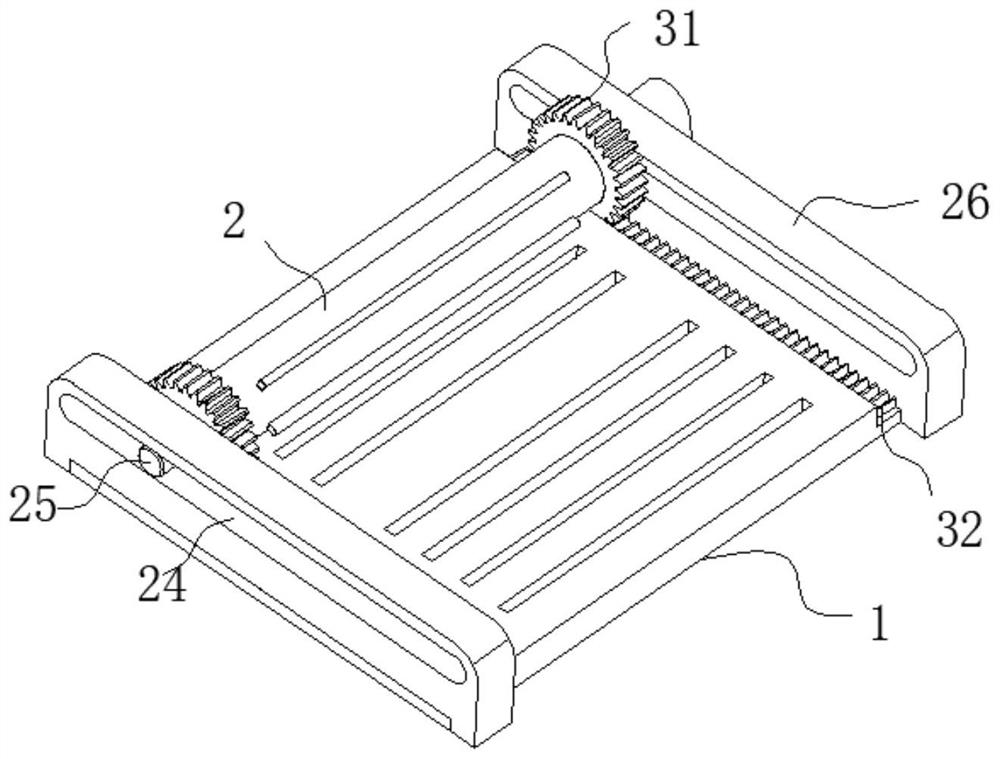

[0030] Example 1, reference figure 1 , The wire mesh groove roller rolling press of this scheme includes a support plate 1, and a pressure roller 2 is arranged on the support plate 1. The pressure roller 2 rolls on the support plate 1 through a rolling and traversing mechanism 3; the axis of the pressure roller 2 A plurality of rolling strips 21 are arranged upward, and the plurality of rolling strips 21 are parallel to the central axis of the pressing roller 2. The support plate 1 is provided with two forming grooves, and the forming grooves include a plurality of forming grooves that match the rolling strips 21. Slot 11.

[0031] In practical application, a rolling and traversing mechanism 3 is used to connect the pressing roller 2 and the support plate 1 .

[0032] When using this device to groov the wire mesh with small holes, soft and easily damaged, first lay the wire mesh between the support plate 1 and the pressing roller 2, and then rotate the pressing roller 2. At t...

Embodiment 2

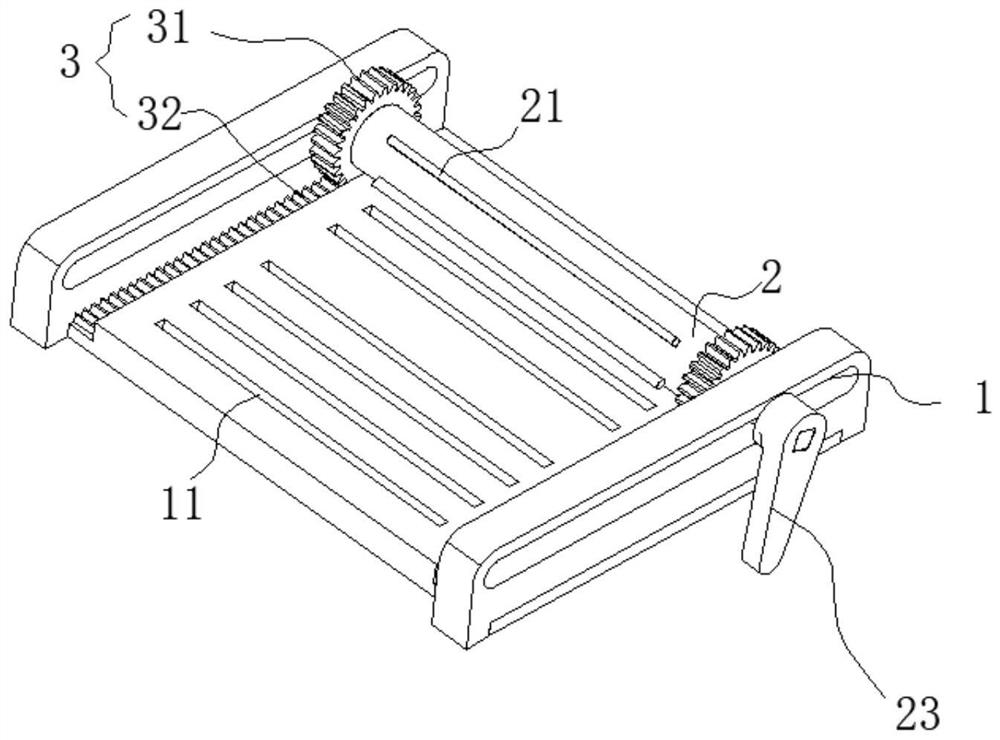

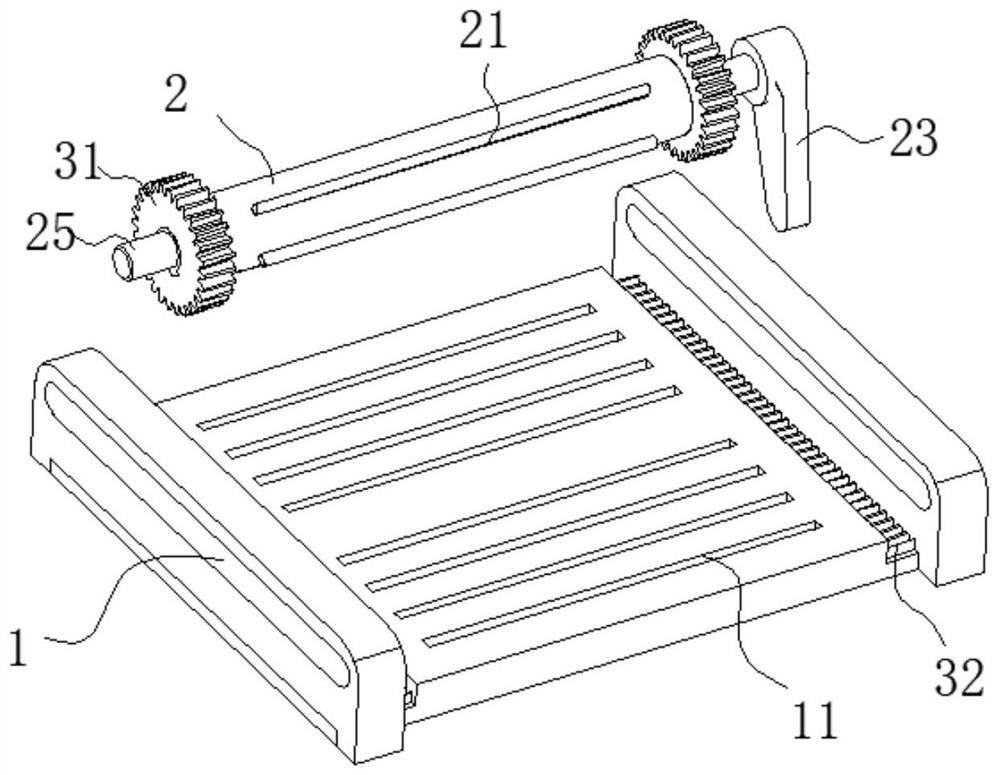

[0036] Example 2, reference figure 1 , figure 2 and image 3 On the basis of Embodiment 1, this embodiment provides a specific solution for the rolling and traversing mechanism 3, including two gears 31 sleeved on the limit shaft 25 and racks 32 arranged on both ends of the support plate 1 ; The rack 32 is used to mesh with the gear 31 .

[0037] When the pressure roller 2 rotates, the gear 31 coaxially connected to the pressure roller 2 also rolls at the same time. Due to the meshing between the gear 31 and the rack 32 on the support plate 1, the freedom of the rack 32 is limited at this time. The pressing roller 2 has the ability to move along the supporting plate 1 and rotate by itself, so that the pressing roller 2 can also move along the supporting plate 1 while rotating, so as to complete the extrusion of the wire mesh on each of the forming grooves 11 .

[0038] refer to Figure 4 , two baffle plates 26 are symmetrically arranged at both ends of the support plate 1...

Embodiment 3

[0046] Example 3, reference figure 2 , On the basis of Embodiment 2, this embodiment provides a specific scheme for driving the pressure roller 2 to rotate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com