Support for shock absorption and isolation of bridge

A technology of shock absorption and isolation and support, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of beam body rising or falling, unstable friction coefficient, structural conflict, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

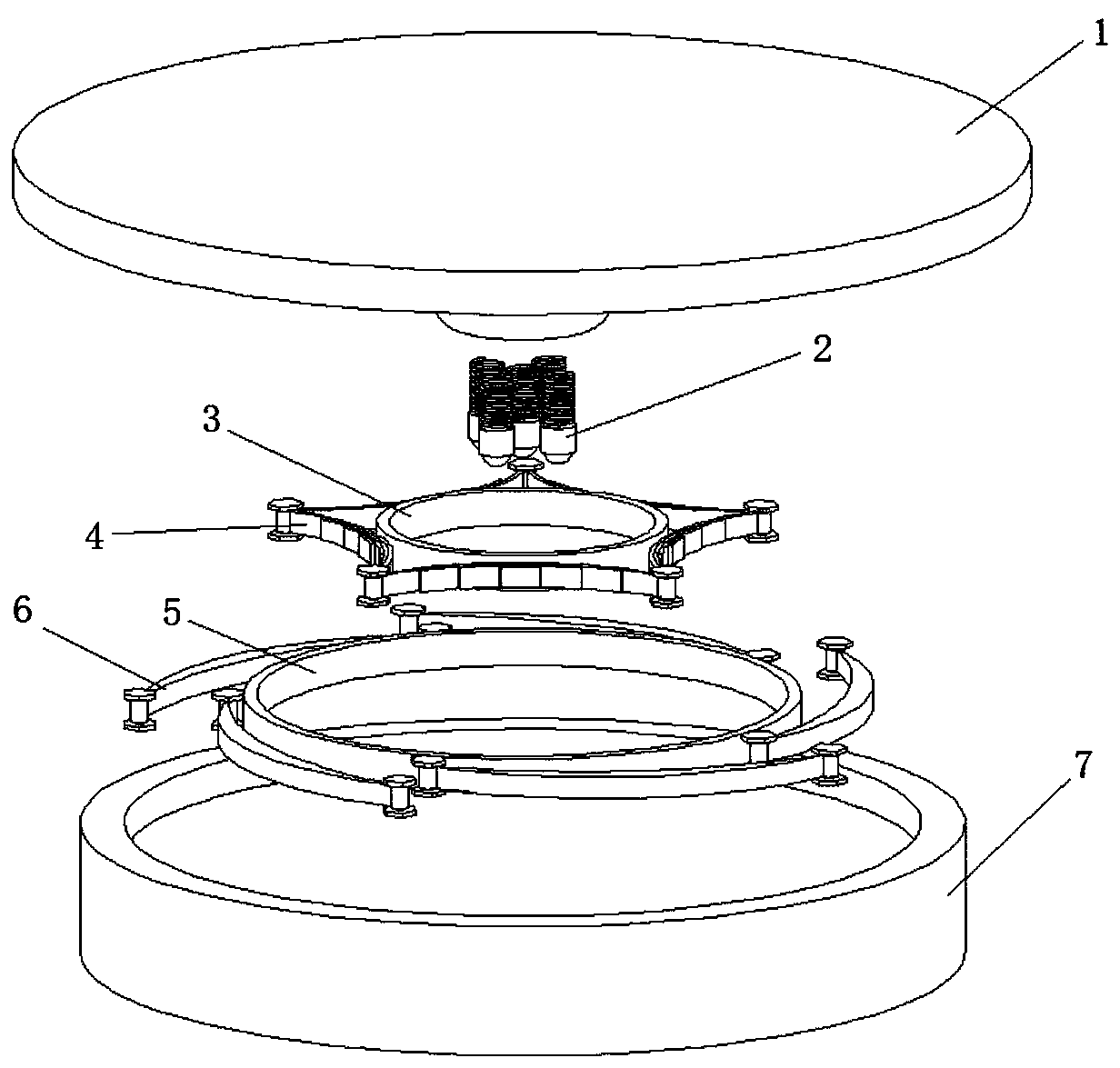

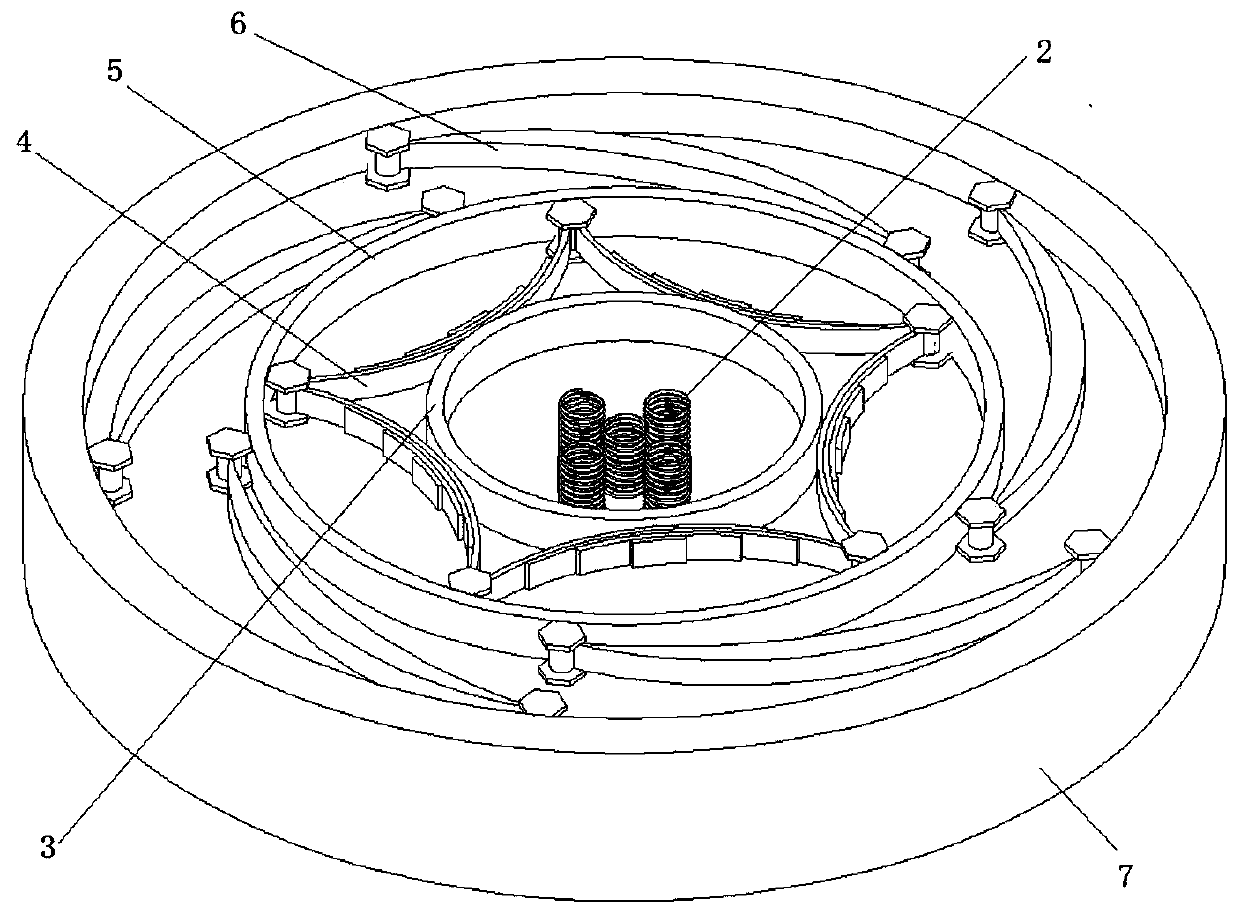

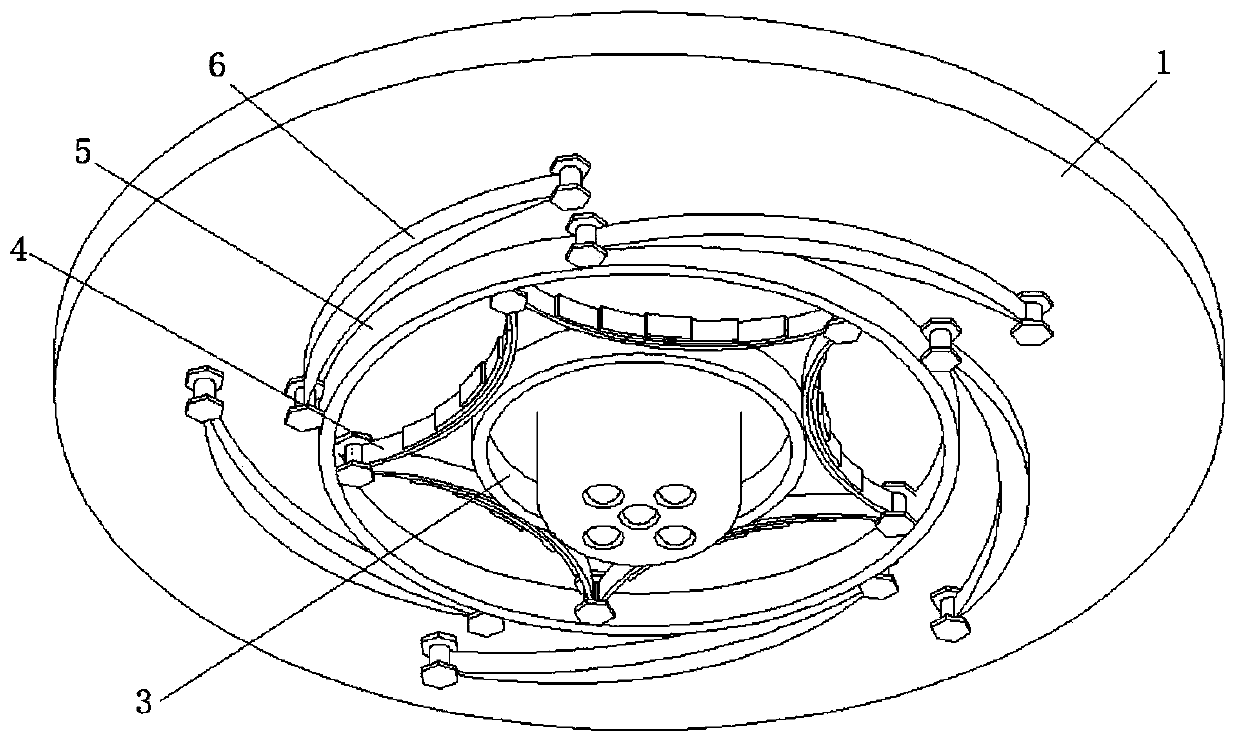

[0037] see Figure 1-7 , a support for shock absorption and isolation of bridges, specifically a shock absorption and isolation support with a limit ring applied to bridges, including an upper seat plate 1, an energy-absorbing assembly, a lower seat plate 7 and at least one set of The elastic component 2, the lower seat plate 7 is provided with a mold cavity, the lower end of the upper seat plate 1 is provided with accommodating cavities equal in number to the elastic components 2, and the elastic components 2 are arranged in each accommodating cavity correspondingly, The upper seat plate 1 is slidably arranged on the bottom surface of the cavity through the elastic component 2, and the energy absorbing component is arranged in the cavity and is located between the lower end of the upper seat plate 1 and the inner wall of the cavity.

[0038] In actual use, the upper seat plate is connected to the bottom surface of the beam body to support the beam body, and the lower seat pla...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the energy-absorbing assembly includes an inner limit ring 3 and at least three leaf springs 4, and a plurality of leaf springs 4 are along the outer circumference of the inner limit ring 3. Uniformly arranged, the single plate spring 4 connects the inner wall of the cavity and the outer wall of the inner limiting ring 3 , and the lower end of the upper seat plate 1 is arranged in the inner limiting ring 3 .

[0055] Preferably, the leaf spring is hinged to the inner side wall of the cavity, and is fixedly connected to the inner limiting ring, that is, welded.

[0056] In actual use, the energy-absorbing component can only be equipped with an inner limit ring and a leaf spring to dissipate energy, that is, the method of this embodiment, or an inner limit ring, an outer limit ring, a leaf spring and a damper Energy consumption is the method of Embodiment 1, and the specific setting method should be selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com