A comprehensive control method for solenoid valve group

A technology of comprehensive control and solenoid valve group, which is applied in the direction of transmission device control, valve operation/release device, valve device, etc., can solve the problems that the comprehensive control of solenoid valve cannot be satisfied, and achieve the purpose of filling the lack of solenoid valve control system and shortening the fault The effect of investigation time and system recovery time, high real-time reliable electromagnetic valve group mutual logic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

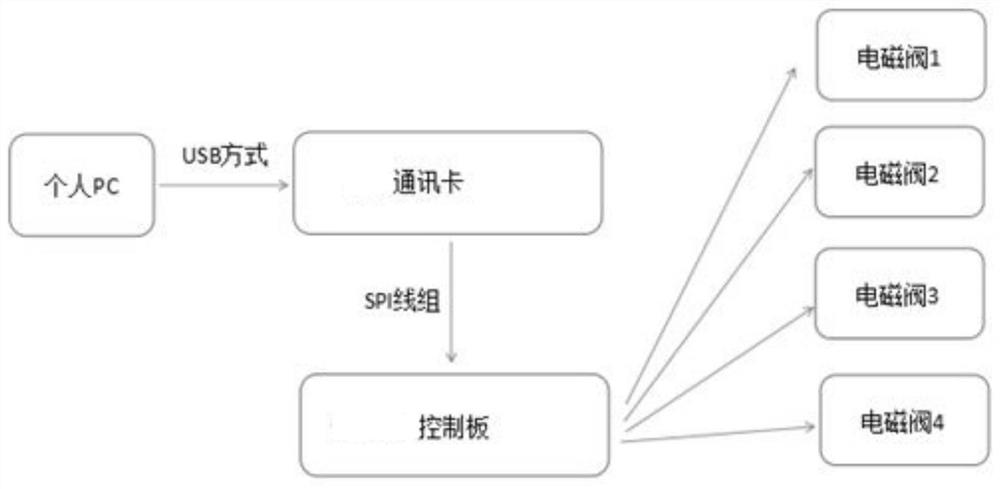

[0026] like figure 1 As shown, the present invention is connected to the control board through the communication card at the PC end, and then the independent control line is drawn from the control board to the solenoid valve harness on the valve body for comprehensive control.

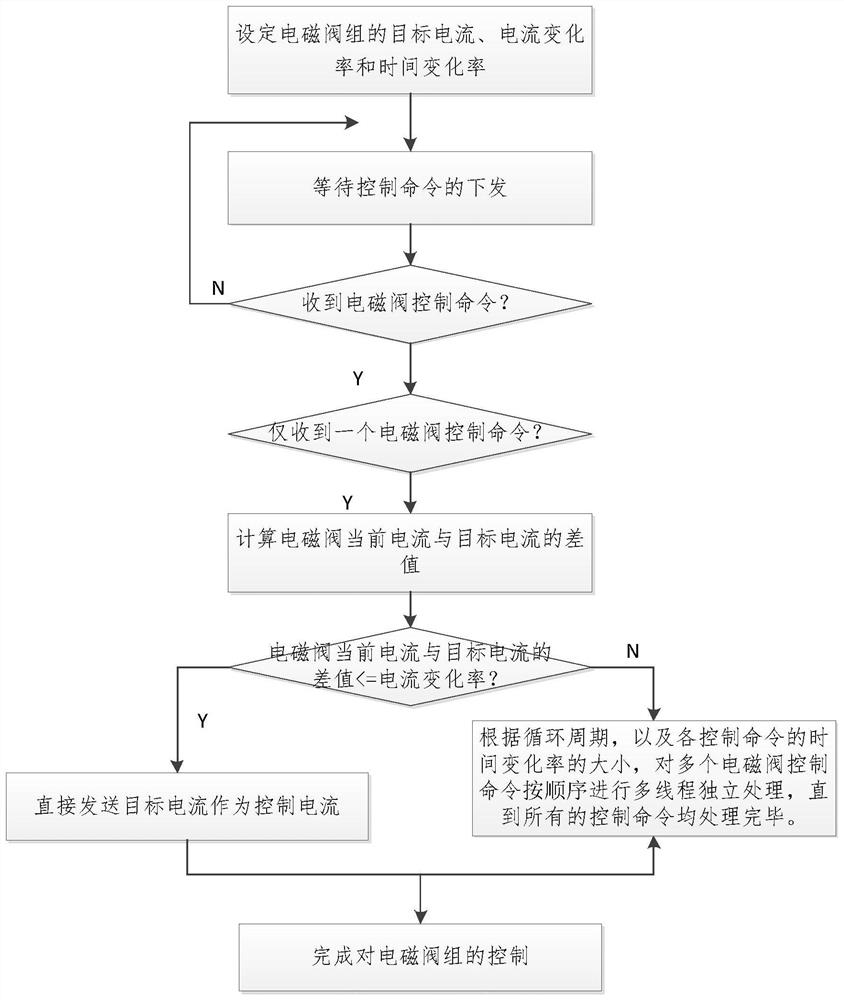

[0027] like figure 2 , taking the cycle period of 100ms as an example, the control method of the present invention is described as follows:

[0028] 1. When no control command is received, the PC side performs a repeated waiting cycle with a cycle of 100ms. At this time, the internal operation of the computer occupies very low resources.

[0029] 2. When the PC receives the control command sent by the user within 100ms, it immediately exits the 100ms waiting loop and sends control current to the solenoid valve that the user requests to control.

[0030] Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com