Automatic feeding device for grain drying

An automatic feeding and grain technology, applied in drying, drying solid materials, lighting and heating equipment, etc., to ensure efficiency, easy installation and disassembly, and improve uniformity and thoroughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

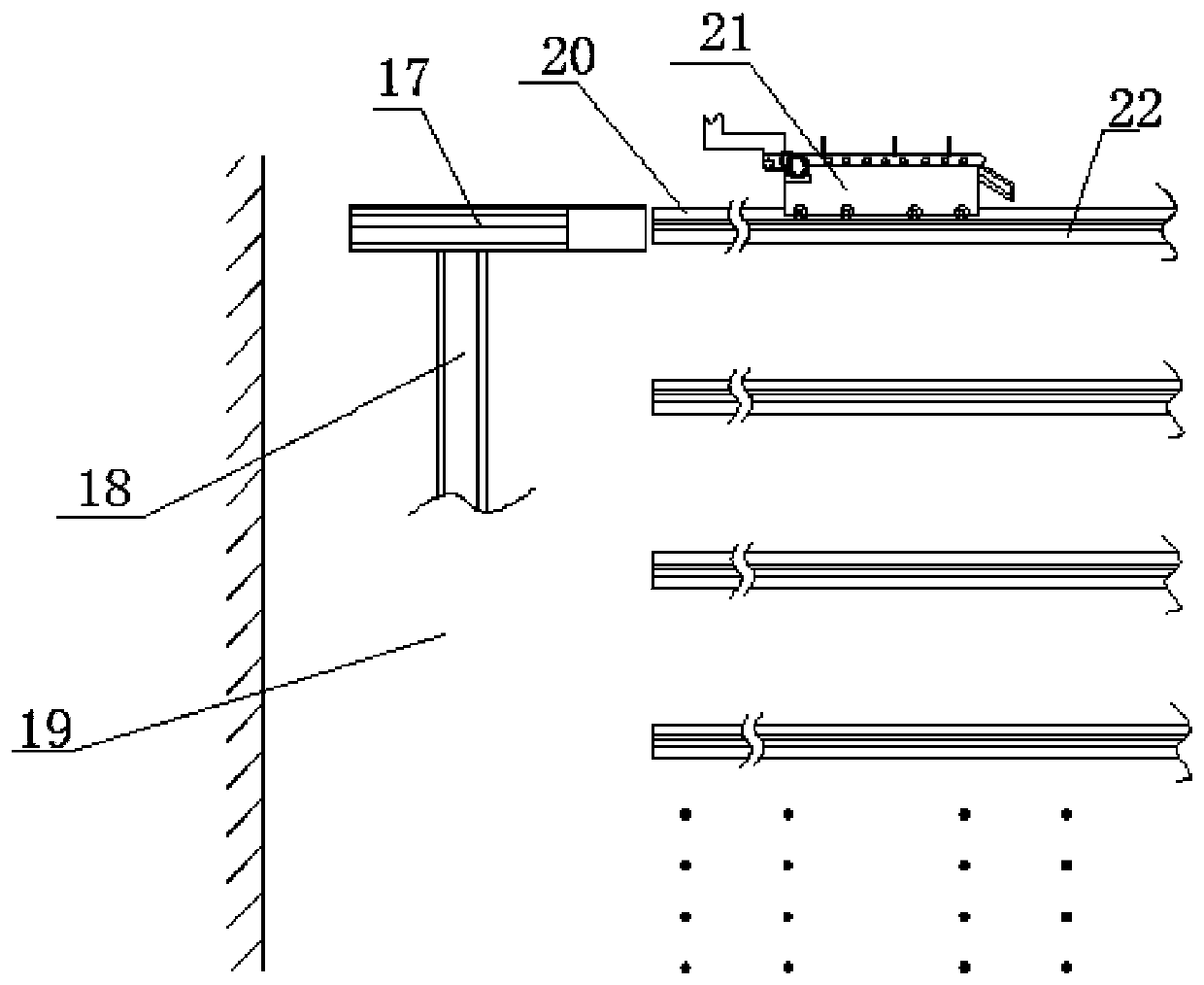

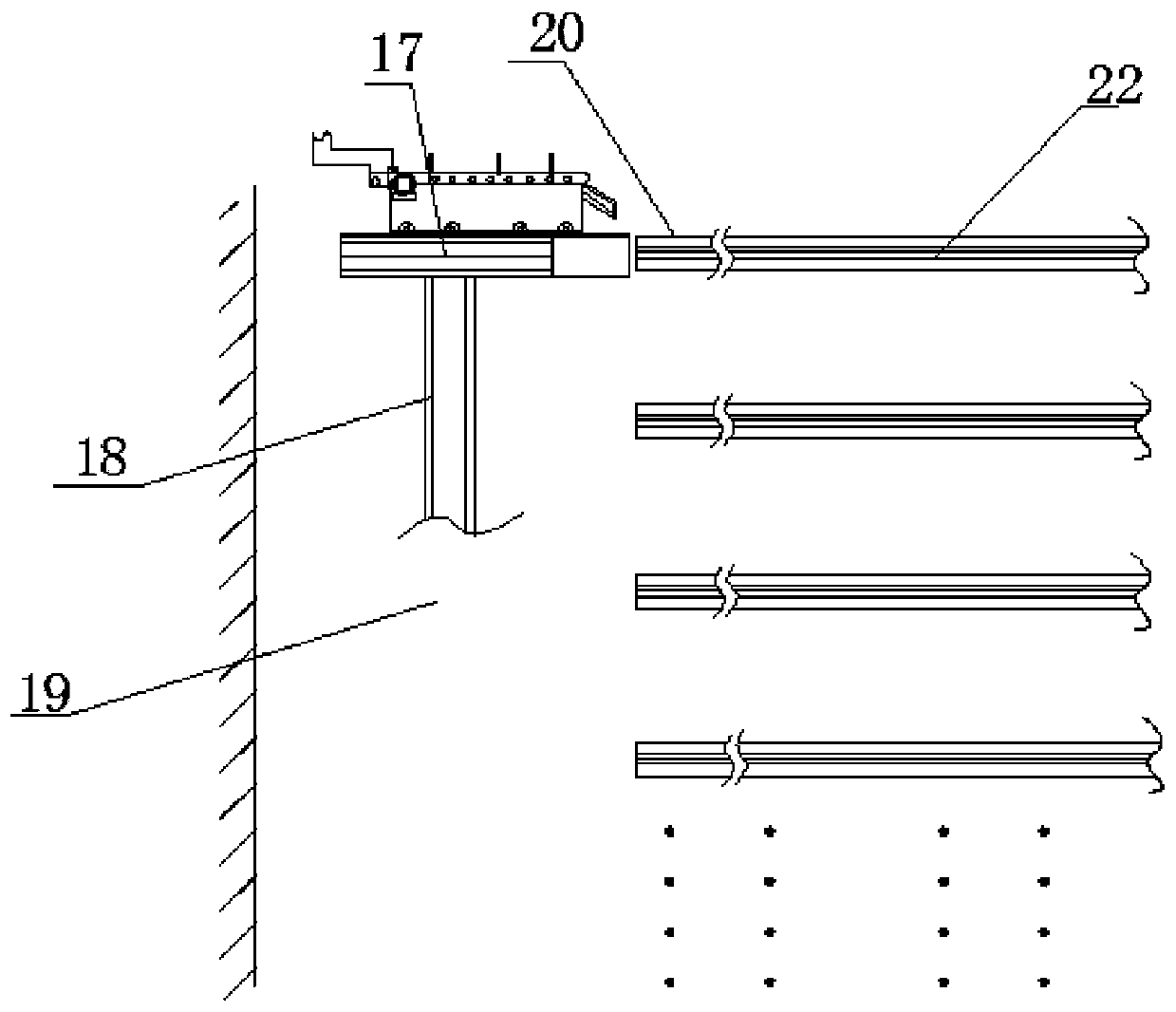

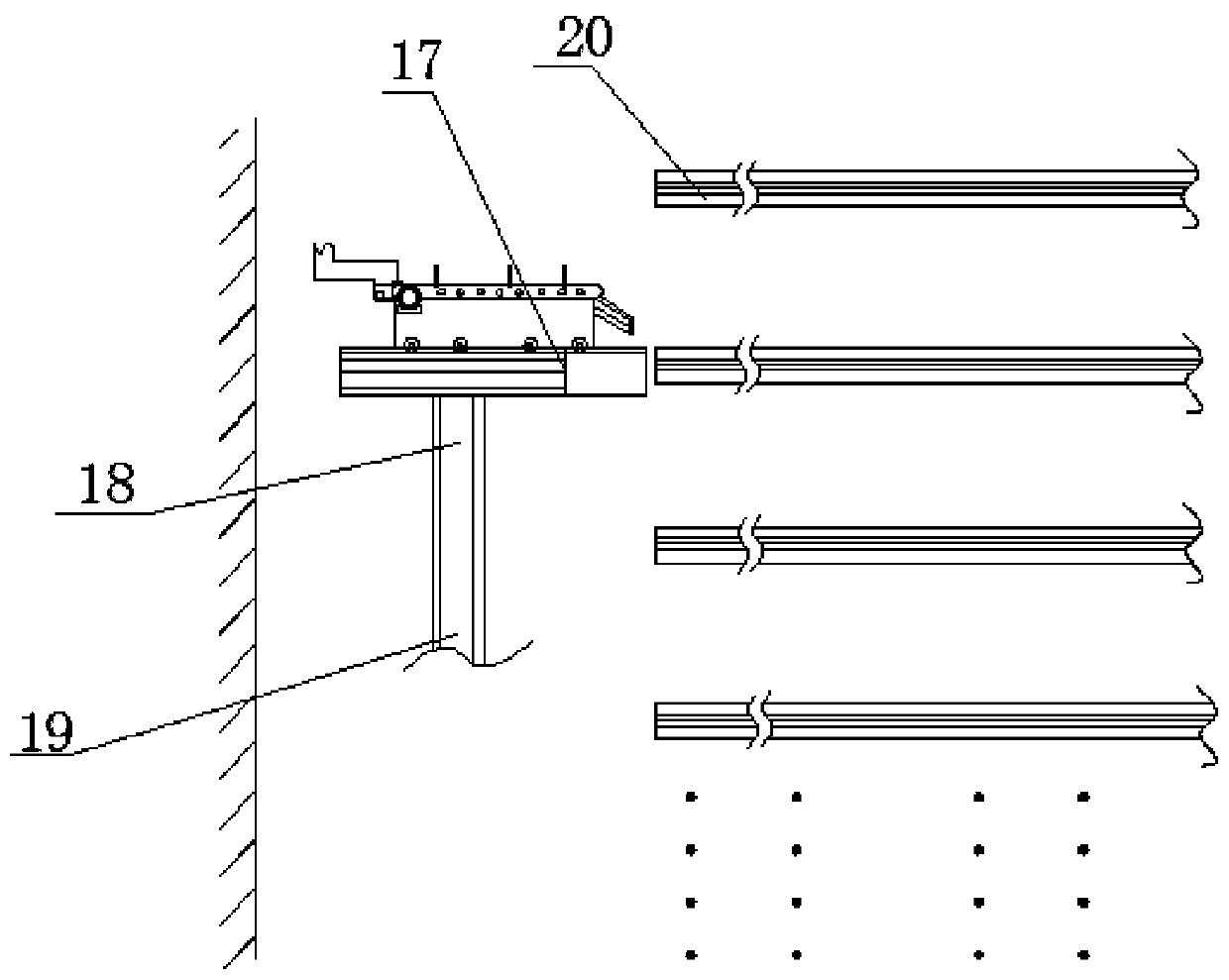

[0027] see Figure 1-7 , in an embodiment of the present invention, an automatic feeding device for grain drying, which is used to flatly feed the grain output by the hoist of the grain drying equipment on each layer of drying laminate 22, which includes feeding Tiling mechanism 21, mobile drive assembly, lifting transfer platform mechanism and transfer channel 19, wherein, one side of each layer of drying laminate 22 is provided with a vertical transfer channel 19, and the lifting transfer platform mechanism can be lifted Set in the transfer channel 19, the two sides of each layer of drying laminates are provided with walking tracks 20, and the moving drive assembly is also provided on the feeding flat mechanism, so that the moving drive assembly can make The feeding and laying mechanism automatically walks along the walking track, and the feeding and laying mechanism can walk on the lifting transfer platform mechanism, so that the feeding and laying mechanism can work on dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com