Molten steel sampling instrument and using method thereof

A sampling instrument and molten steel technology, applied in the field of iron and steel smelting, to achieve the effect of improving the sampling success rate, improving the sampling efficiency and reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

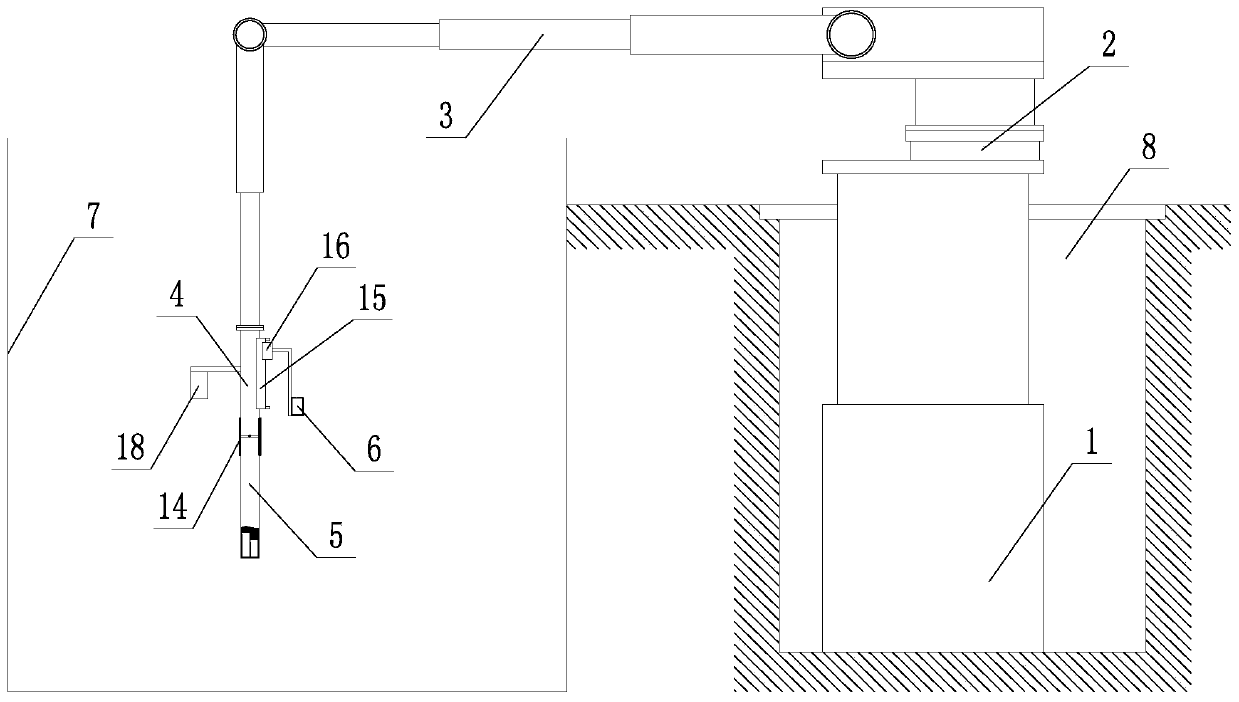

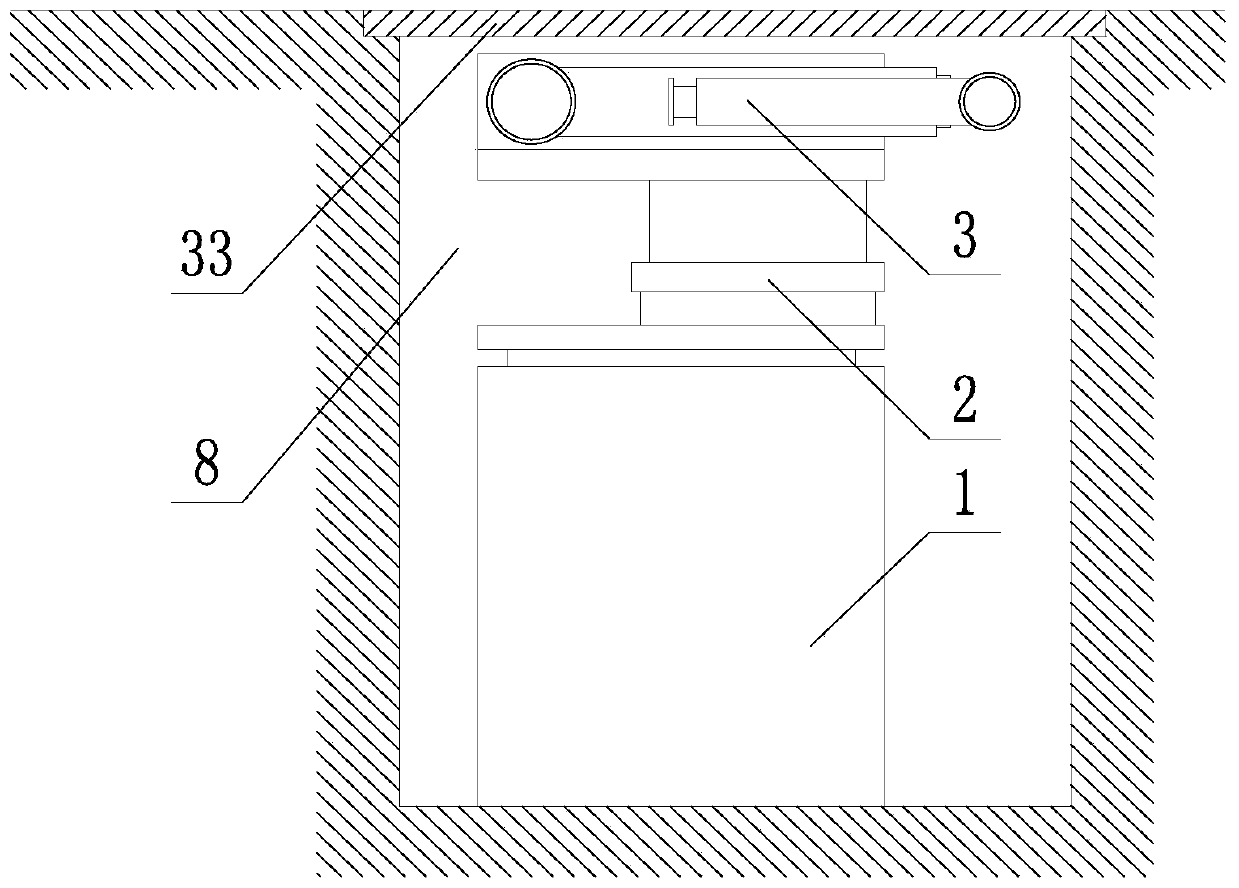

[0050] Such as Figure 1-8 As shown, a molten steel sampling instrument includes a lifting platform 1, a rotary platform 2, a mechanical arm 3, a sampling adapter rod 4, a molten steel sampler 5 and a steel slag sampling box 6; the lifting platform 1 is arranged on the side of the ladle 7 In the foundation pit 8 on the ground, the turntable 2 is installed on the top of the lifting platform 1, the mechanical arm 3 is installed on the turntable 2, and the turntable 2 can rotate 360°; the molten steel sampler 5 and the steel slag sampling box 6 are all connected to the mechanical arm 3 through the sampling adapter rod 4.

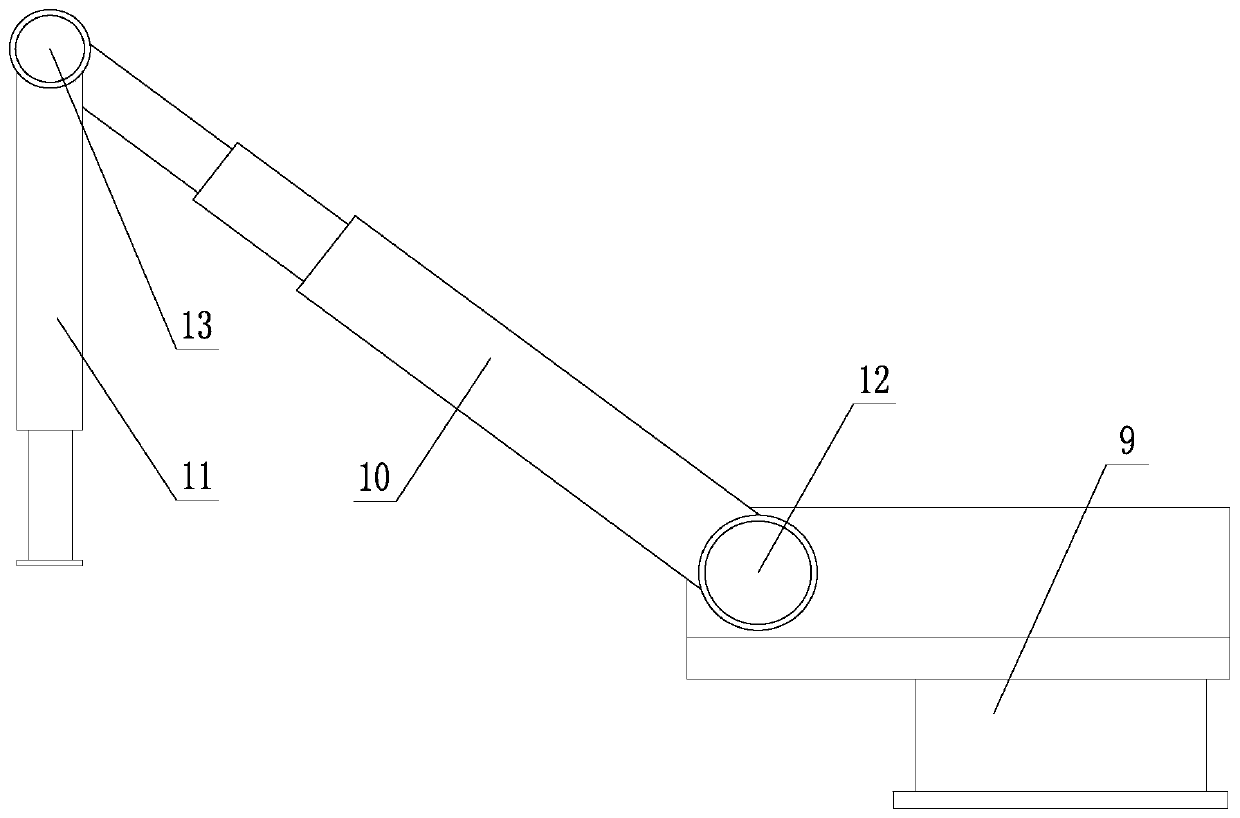

[0051] The mechanical arm 3 includes a base 9, a boom 10 and a small arm 11, the base 9 is installed on the top of the turntable 2, one end of the boom 10 is hinged on the base 9, and a boom is installed at the hinge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com