Hot-pressed light guide plate with high mesh points, backlight, display device and preparation method

A light guide plate and dot technology, applied in light guides, optics, optical components, etc., can solve problems such as top white, scratches, and white spots, and achieve the effects of reducing the number of dots, increasing display brightness, and increasing the active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

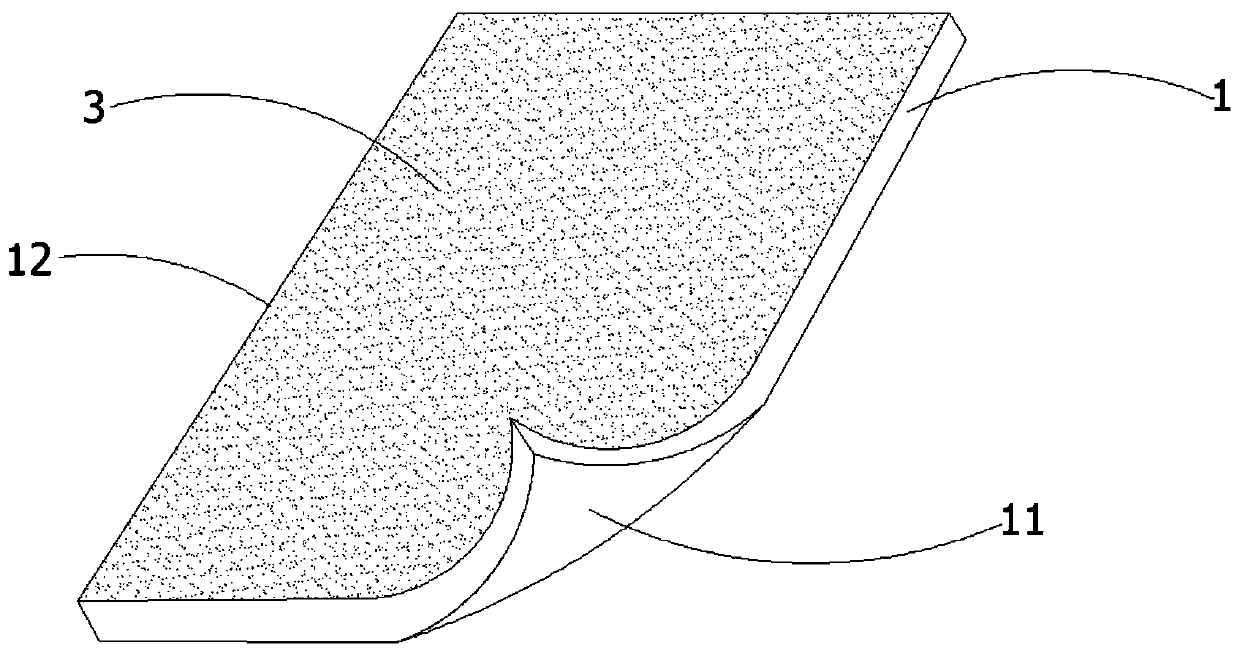

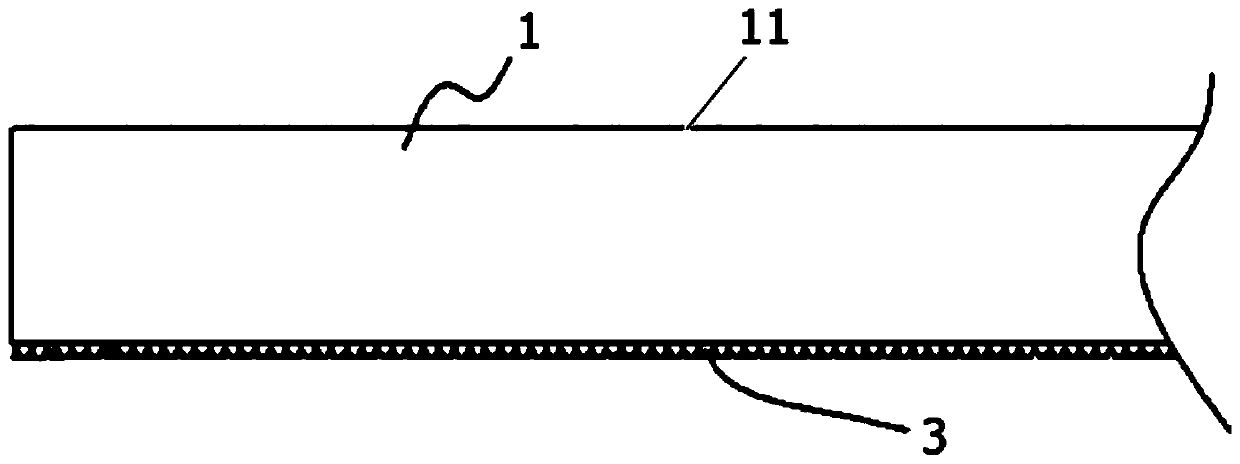

[0024] Such as Figure 1-3 As shown, the heat-pressed light guide plate 1 includes an opposite first surface 11 and a second surface 12, and the second surface is provided with a dot area composed of a plurality of dots 3, and the dot area makes the light entering the light guide plate Capable of emitting from the first surface.

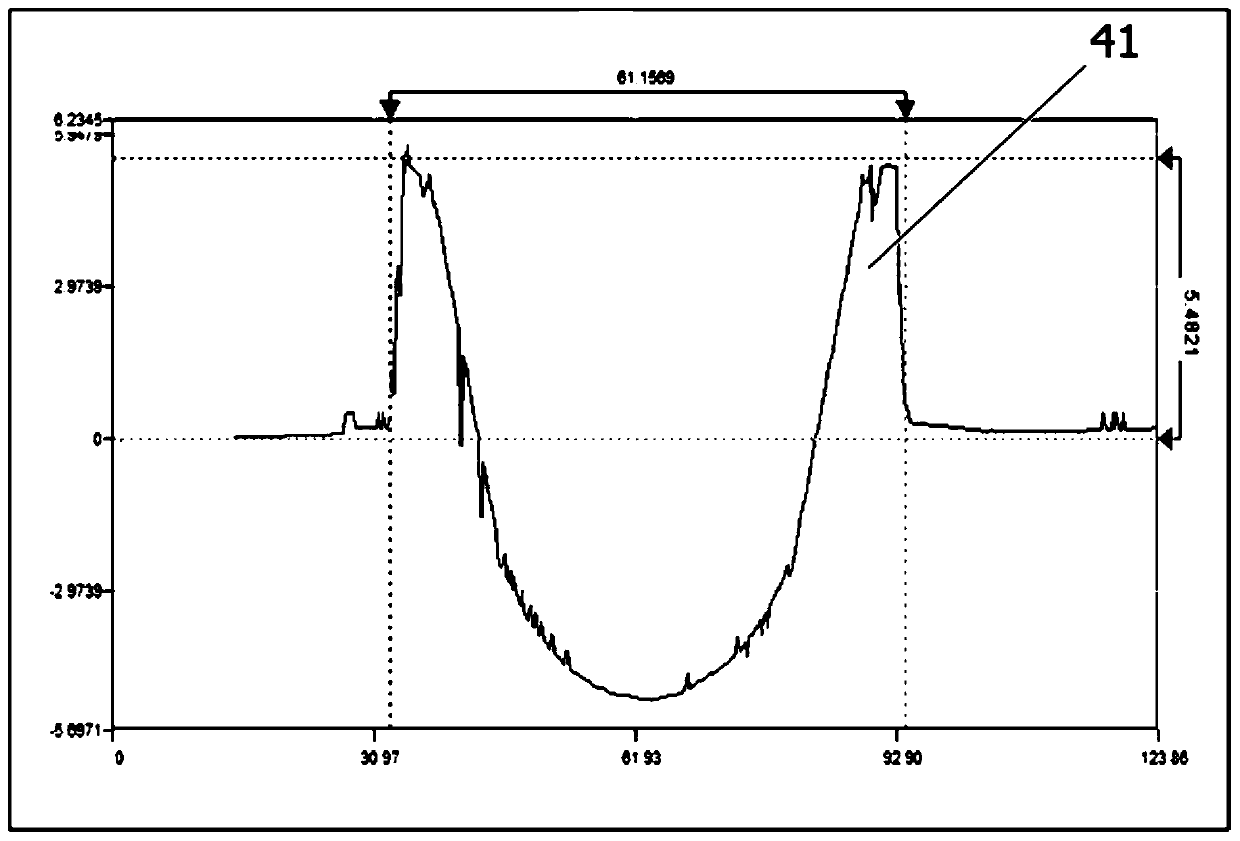

[0025] The dots 3 of the hot-pressed light guide plate need to be hot-pressed and transferred through the mold core 4 having the shape of the annular crater 41, and whether the shape of the ring-shaped crater of the mold core can maintain a good degree of integrity can reach the highest level. The height is the key to determine the height of the dots of the light guide plate after transfer printing.

[0026] In the present invention, the average height of the ring-shaped crater 41 of the mold core before hot-press ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com