Lens module and assembling method thereof

The technology of a lens module and assembly method, which is applied in the field of photography, can solve problems such as image errors, dust pollution, and affecting imaging quality, and achieve the effect of reducing stray light on the image of the image and improving the imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

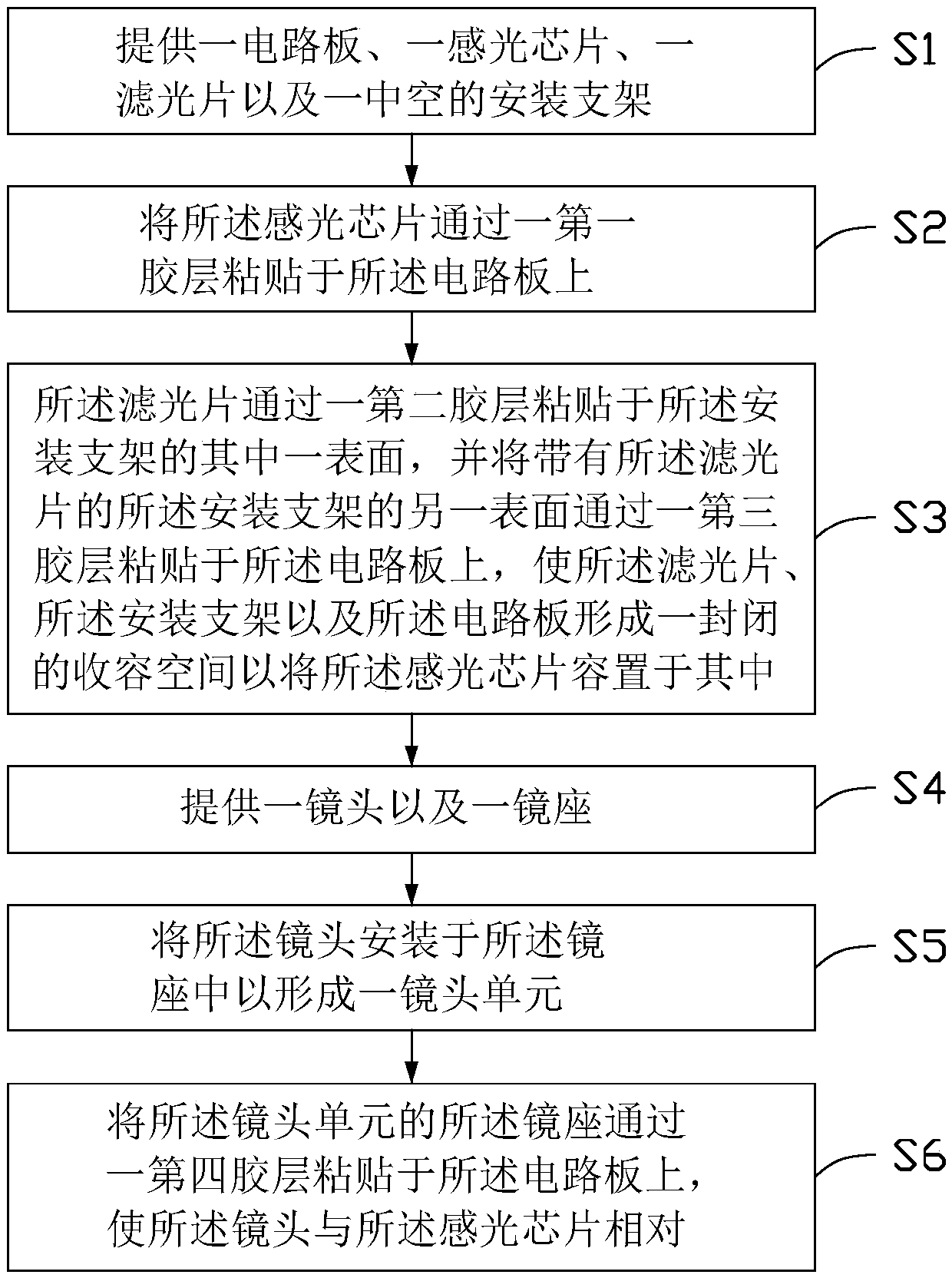

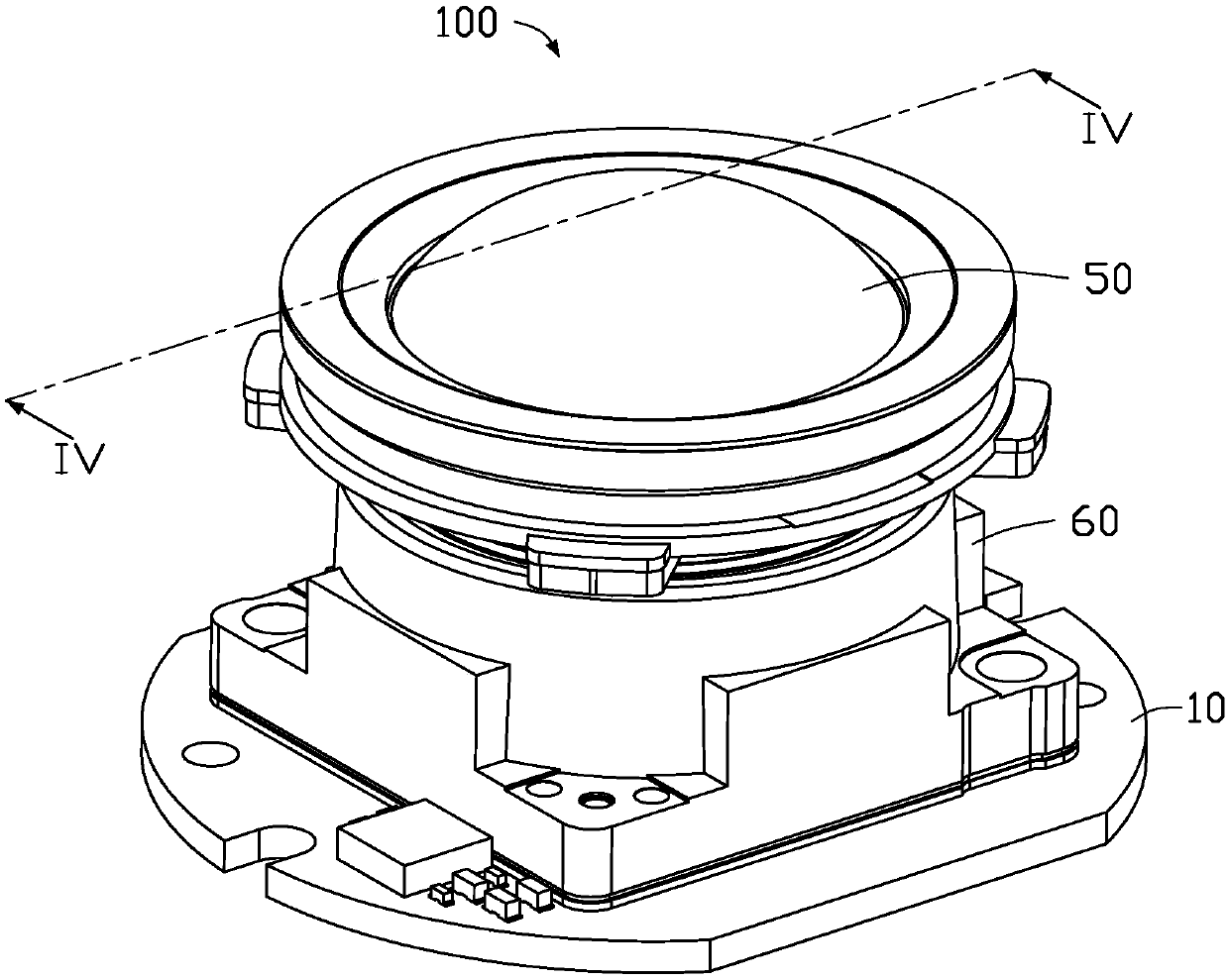

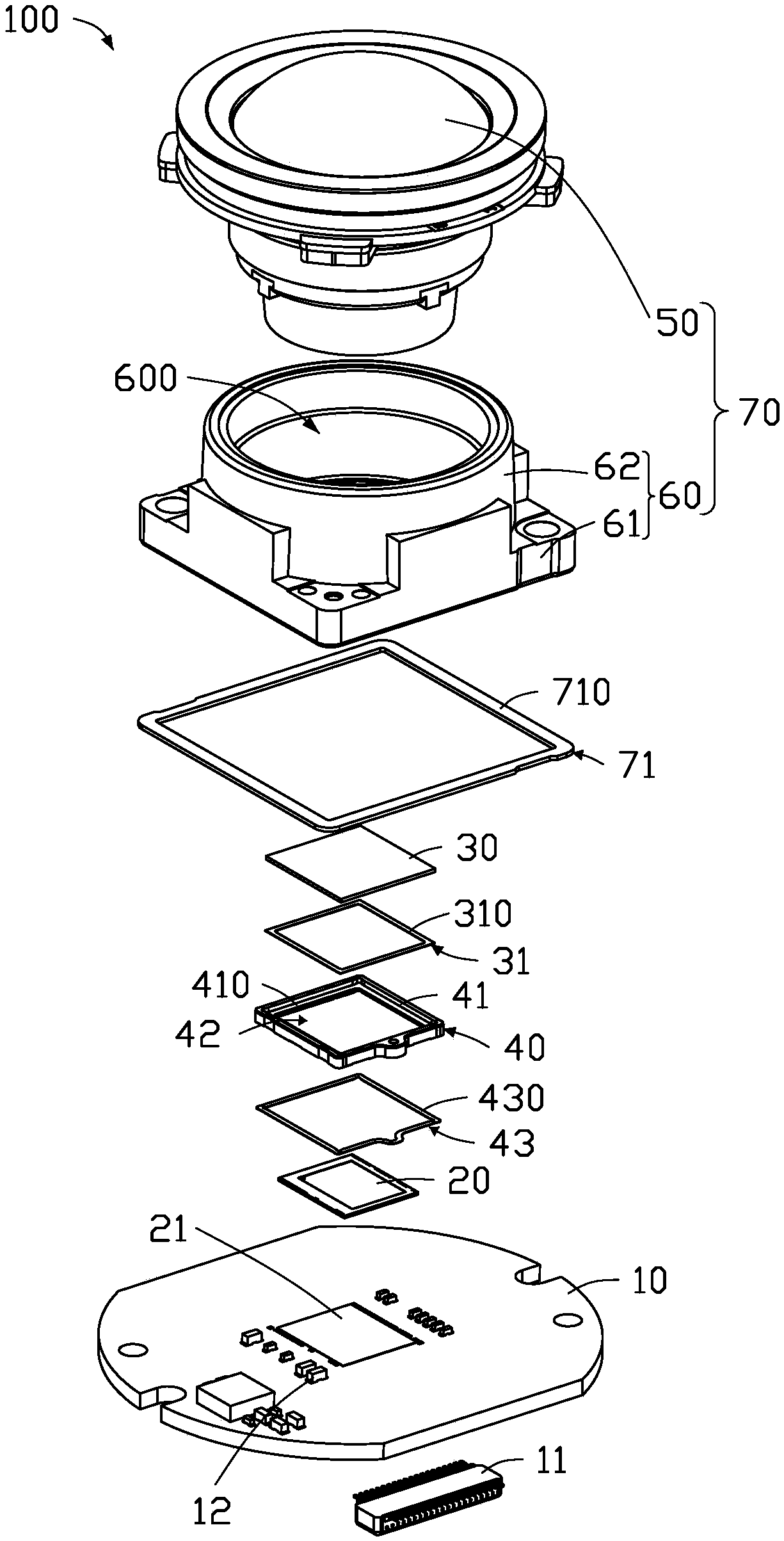

[0016] figure 1 A method for assembling a lens module provided by a preferred embodiment of the present invention is illustrated. According to different requirements, the sequence of steps in the method for assembling the lens module can be changed, and some steps can be omitted or combined. Please also refer to Figure 2 to Figure 4 , the assembly method of the lens module includes the following steps:

[0017] Step S1 : providing a circuit board 10 , a photosensitive chip 20 , a filter 30 and a hollow mounting bracket 40 .

[0018] In this embodiment, the circuit board 10 is a printed circuit board, such as a flexible board, a rigid board, or a rigid-flex board. A connector 11 is mounted on one surface of the circuit board 10, and a connector 11 is mounted on the other surface. A plurality of electronic components 12 .

[0019] In this embodiment, the mounting bracket 40 is substantially square, which includes four first sides 41 connected end to end. The four first sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com