Performance test system and method for battery liquid cooling plate

A testing system and battery fluid technology, applied in secondary battery testing, secondary battery, secondary battery repair/maintenance, etc. Achieve the effect of selection design and reduce test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

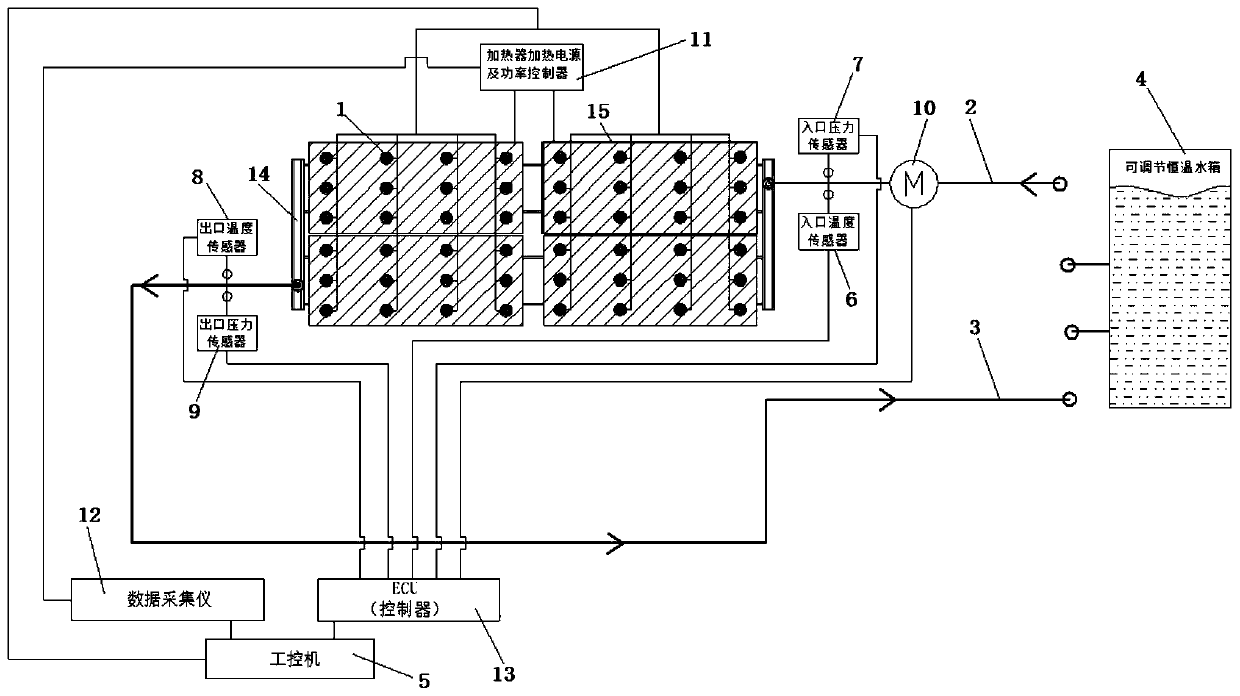

[0025] Please refer to figure 1 , the embodiment of the present invention provides a battery liquid cold plate performance test system, which is suitable for the liquid cold plate subassembly or system assembly located at the bottom or side of the battery module grouped by square cells and pouch cells. The completed performance test shows that the structure of the battery liquid cold plate is mainly stamped plate type and harmonica tube, and the working medium is the liquid cold plate in the cooling liquid mode. The test system includes a test module 1, water inlet pipe 2, water outlet pipe 3, Constant temperature water tank 4 and industrial computer 5.

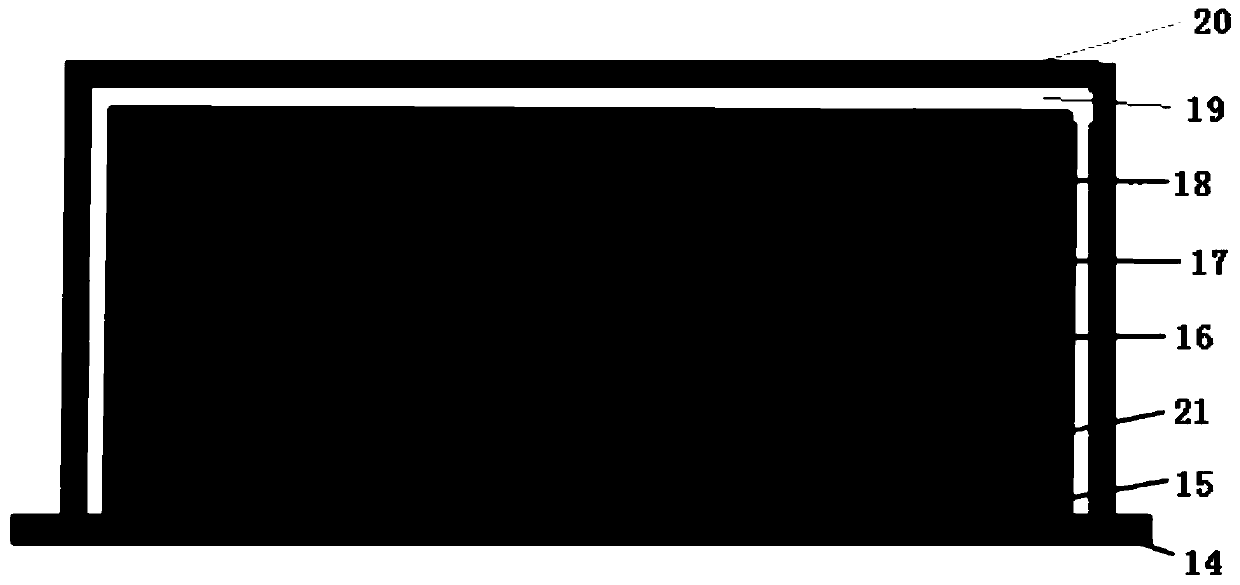

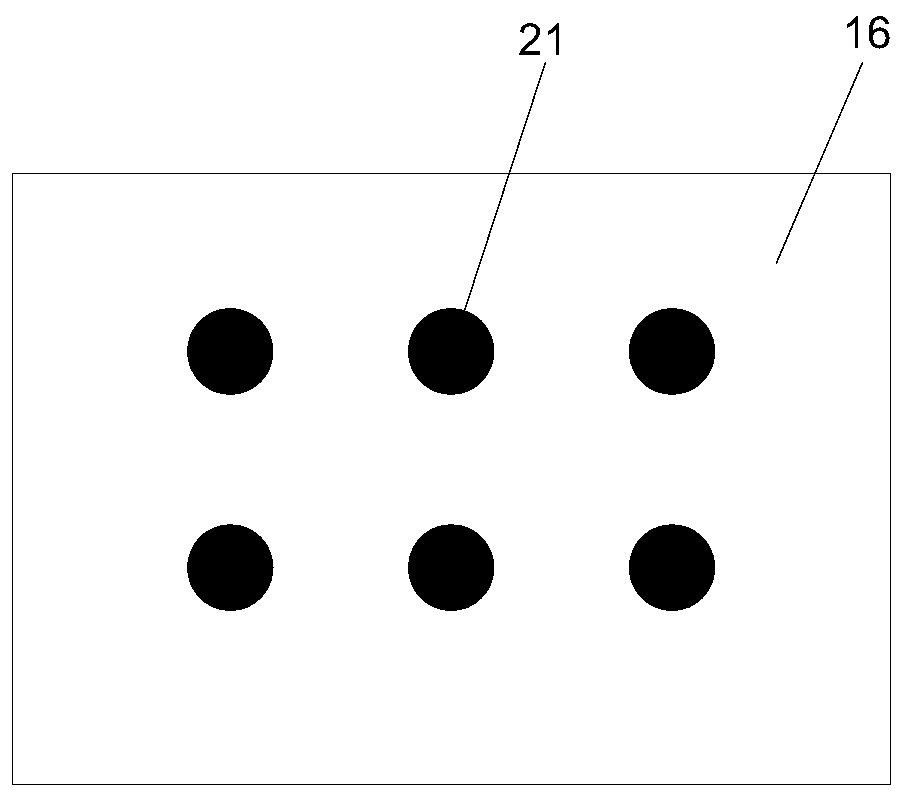

[0026] Please refer to figure 2 , the test module 1 simulates battery charging and discharging to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com