Springback control method for ultrahigh-strength steel roll-formed part

A technology of ultra-high-strength steel and control methods, which is applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of reduced equipment utilization, material waste, labor-hour consumption, etc., and achieves elimination of material waste, efficient and accurate operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

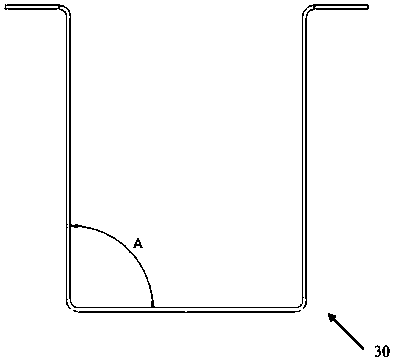

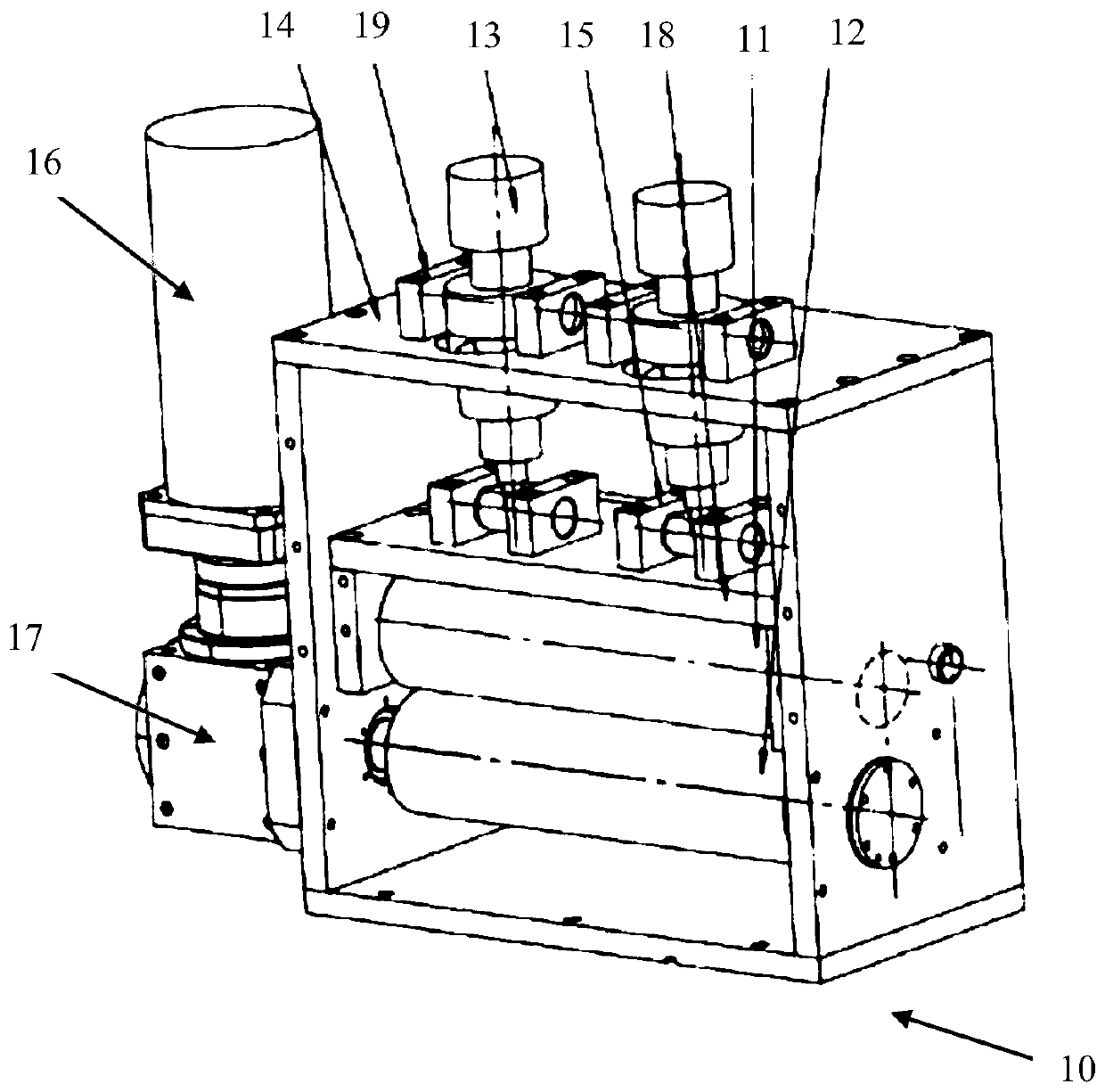

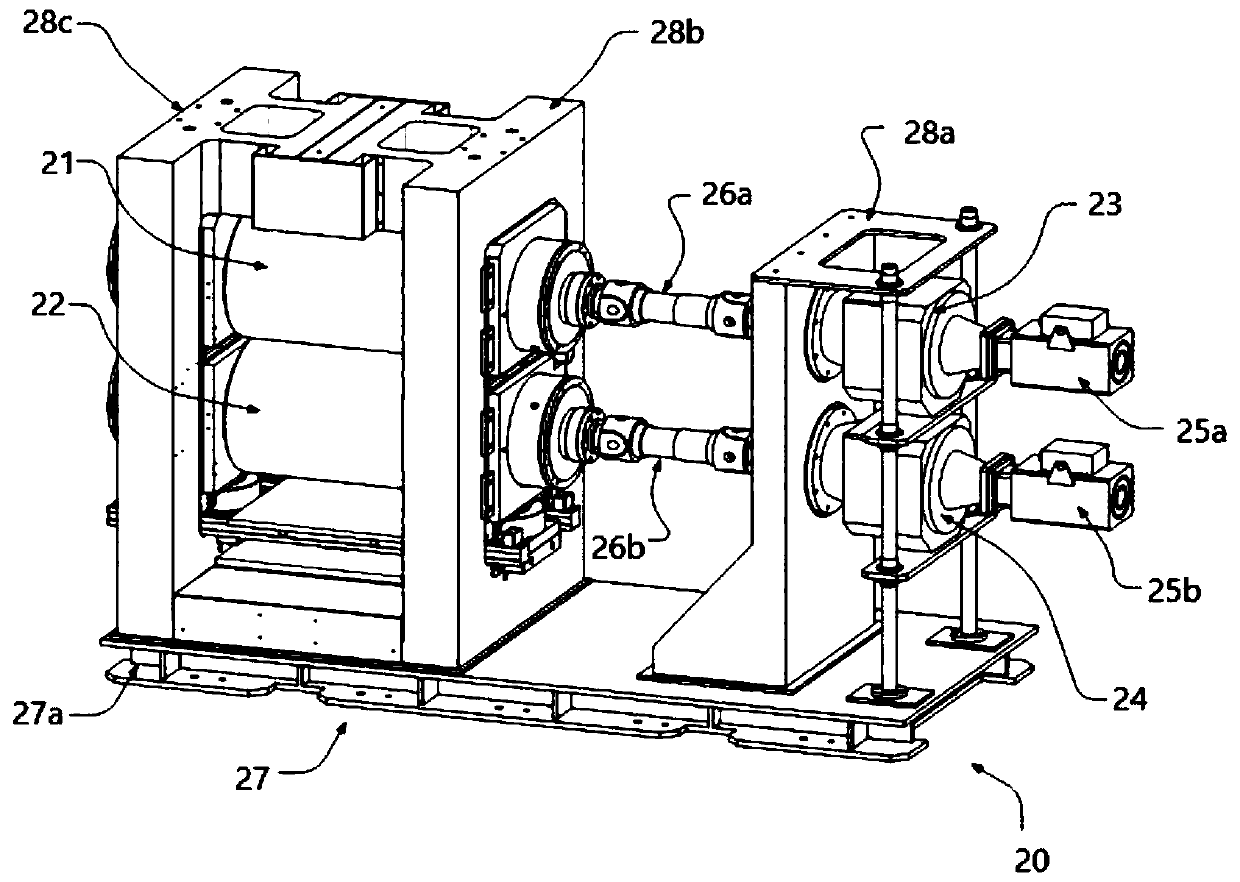

[0025] The embodiment of the present invention discloses a springback control method of an ultra-high-strength steel roll-formed part. The ultra-high-strength steel roll-formed part adopts a steel strip made of ultra-high-strength steel through a roll forming process and a springback compensation pass. Process, after the roll forming pass process is completed and before the springback compensation pass process, the angle of the ultra-high-strength steel roll-formed part is measured, based on the detection angle of the ultra-high-strength steel roll-formed part and the pre-calibrated angle springback compensation The coefficient calculates the angle deviation value, and transmits the angle deviation value to the servo motor control system of the springback compensation pass process, and the springback compensation pass process performs angle springback compensation on the ultra-high-strength steel roll-formed parts according to the angle deviation value.

[0026] In order to ena...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com