3D printing liquid supplementing mechanism and using method thereof

A 3D printing and printing liquid technology, applied in the field of 3D printing, can solve the problems of affecting printing time, poor fluidity of liquid resin, and liquid resin cannot be replenished immediately, so as to achieve a better effect of replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

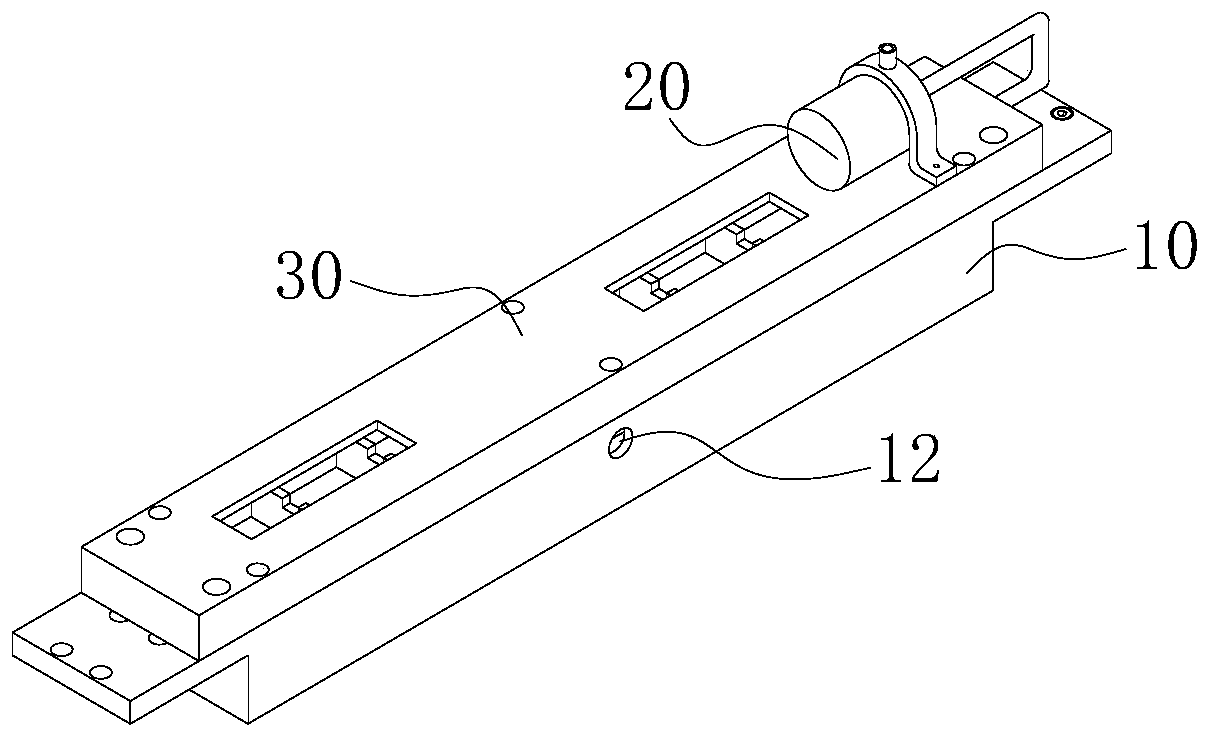

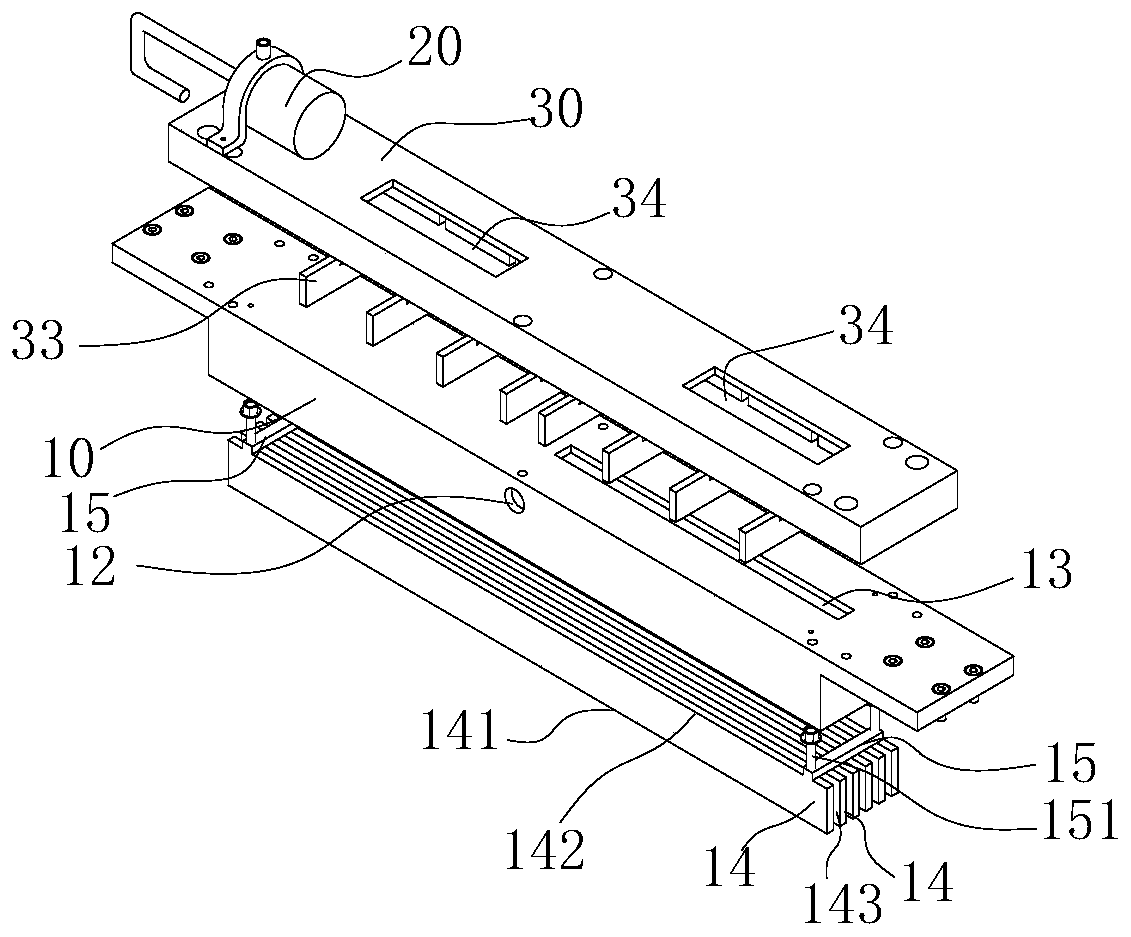

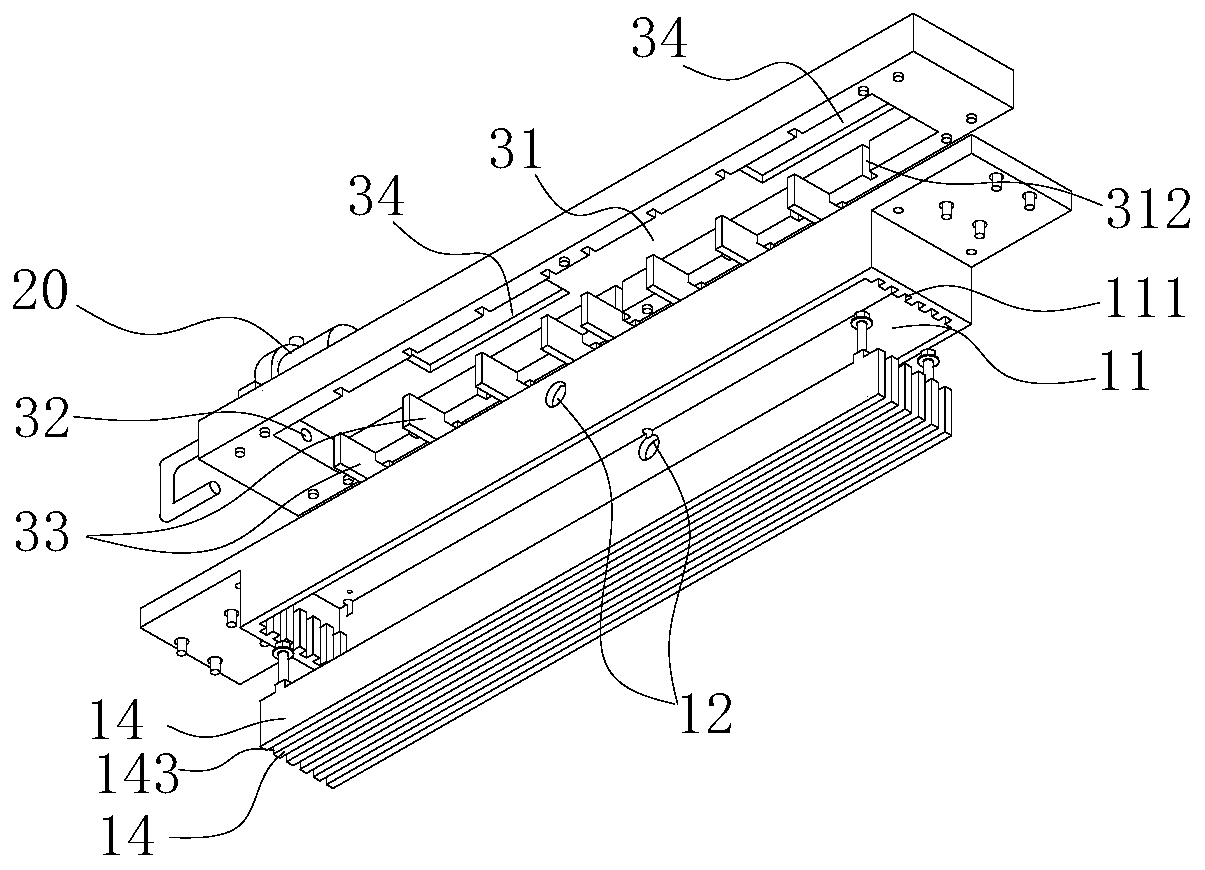

[0057] Embodiments of the present invention will be described in detail below.

[0058] Such as Figure 1 to Figure 6 As shown, the 3D printed liquid replenishment mechanism includes a liquid replenishment device 10 and a vacuum pumping device 20. The liquid replenishment device 10 is provided with a housing chamber 11 inside, and the housing chamber 11 has an opening. The opening of the housing chamber 11 is located in the liquid replenishment device On the end face of the bottom end of 10, the suction end of the vacuum device 20 communicates directly or indirectly with the accommodation chamber 11, and the interior of the accommodation chamber 11 is equipped with a plurality of partition walls 14, and the partition walls 14 There is a gap 143 between them, and the end surface of the partition wall 14 close to the opening is in close contact with the end surface of the bottom end of the liquid replacement device 10 .

[0059] The cavity provided inside the liquid replenishme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com