Intelligent speed regulating system for coal mining and coal handling of comprehensive mechanized coal mining face and operating method

A fully mechanized mining face, intelligent speed regulation technology, applied in the direction of transportation and packaging, conveyor control devices, conveyor objects, etc., can solve the problem of reducing the life of the motor, failure of the scraper conveyor, coal shearer and scraper conveyor Overload and other problems of the machine can be solved to achieve the effect of improving real-time performance and stability, avoiding low work efficiency and accurate coal loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

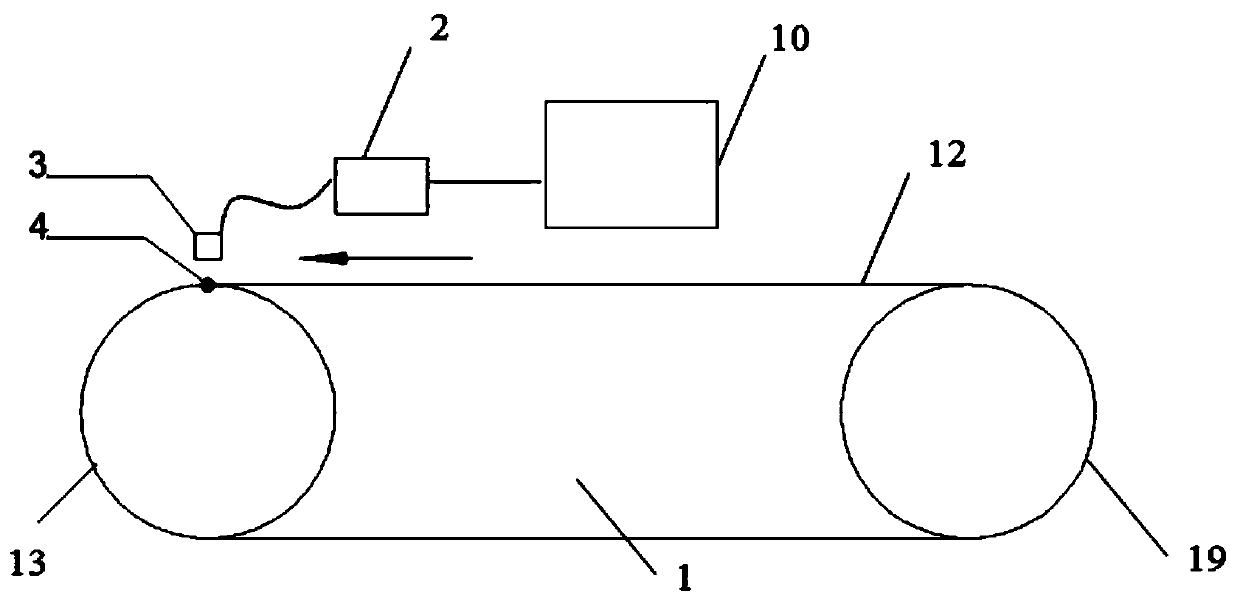

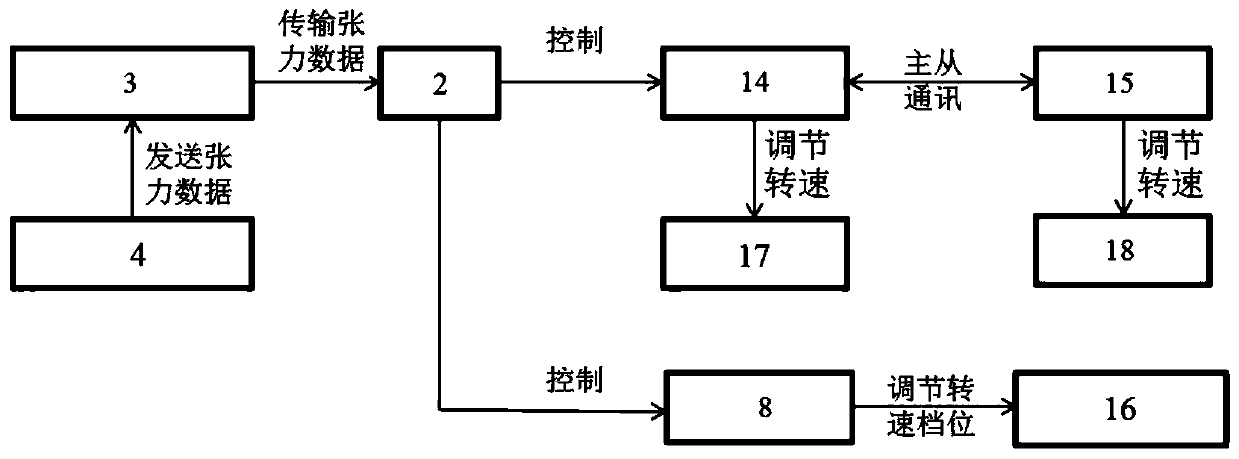

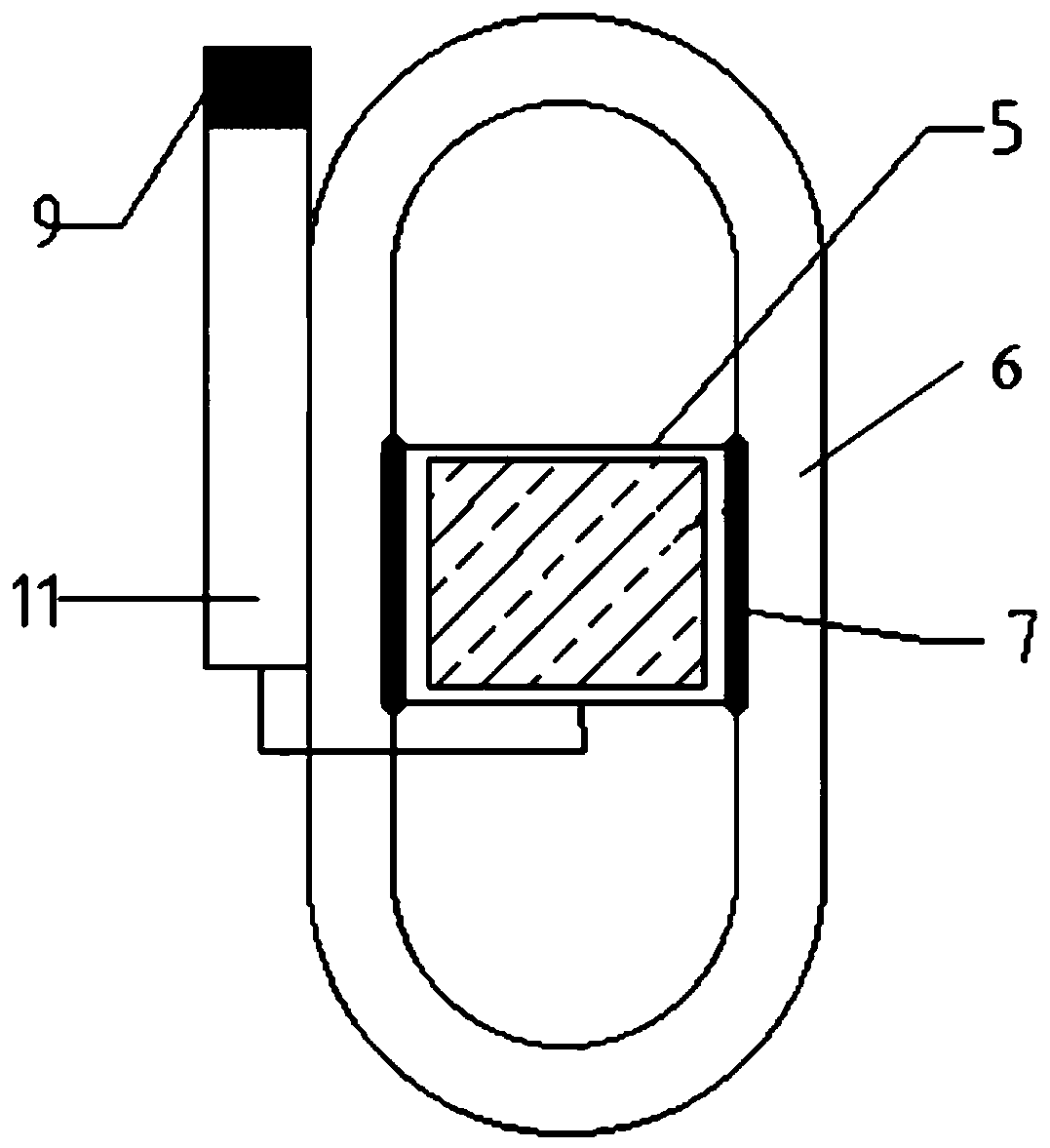

[0040] An intelligent speed regulation system for coal mining and transportation in fully mechanized mining face, figure 1 with figure 2 As shown, acting on the scraper conveyor 1 and the coal shearer 10, the coal shearer 10 includes a coal mining traction motor 16; the scraper conveyor 1 includes a machine head, a machine tail and a scraper chain 12, and the machine head includes a machine head The head motor 17 and the nose sprocket 13, the nose sprocket 13 is set on the rotating shaft of the nose motor 17; on the rotating shaft; the tail sprocket 19 and the head sprocket 13 are connected by the scraper chain 12; the scraper chain 12 is composed of several round-link chains 6 buckled together from the end to the end, and the round-link chain 6 includes two An arc segment and two cylinder segments, the arc segment and the cylinder segment are connected end to end;

[0041] The intelligent speed control system includes a wireless tension monitoring device 4, an eddy current...

Embodiment 2

[0054] The working method of an intelligent speed regulation system for coal mining and coal transportation in a fully mechanized mining face provided by Embodiment 1 includes the following steps:

[0055] (1) The tension value of the meshing point between the head sprocket 13 and the scraper chain 12 of the scraper conveyor 1 under the rated load is stored in the main control computer 2 .

[0056] (2) Turn on the intelligent speed regulation system for coal mining and transportation in fully mechanized mining face.

[0057] (3) During the operation of the intelligent speed-regulating coal mining system, when the scraper chain 12 meshes with the head sprocket 13, the eddy current proximity switch 11 controls the wireless tension monitoring device 4 to send the tension data of the current meshing point, and the wireless signal receives The device 3 receives the tension data and transmits the tension data to the main control machine 2, and the main control machine 2 stores the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com