Drying method, drying system and zinc-nickel electroplating process in electroplating zinc-nickel process

A technology of zinc-nickel electroplating and drying system, which is applied in the direction of drying gas arrangement, drying, drying machine, etc. It can solve the problems of relatively high requirements for the oven, affecting the process, and limited oven space, so as to speed up product drying and save water. The effect that resources, the drying method are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

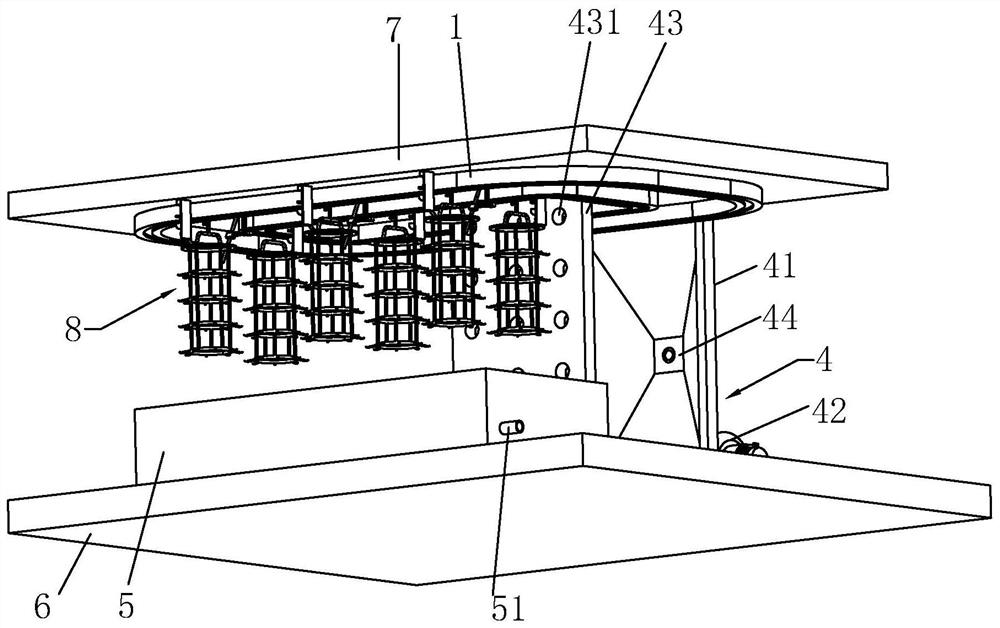

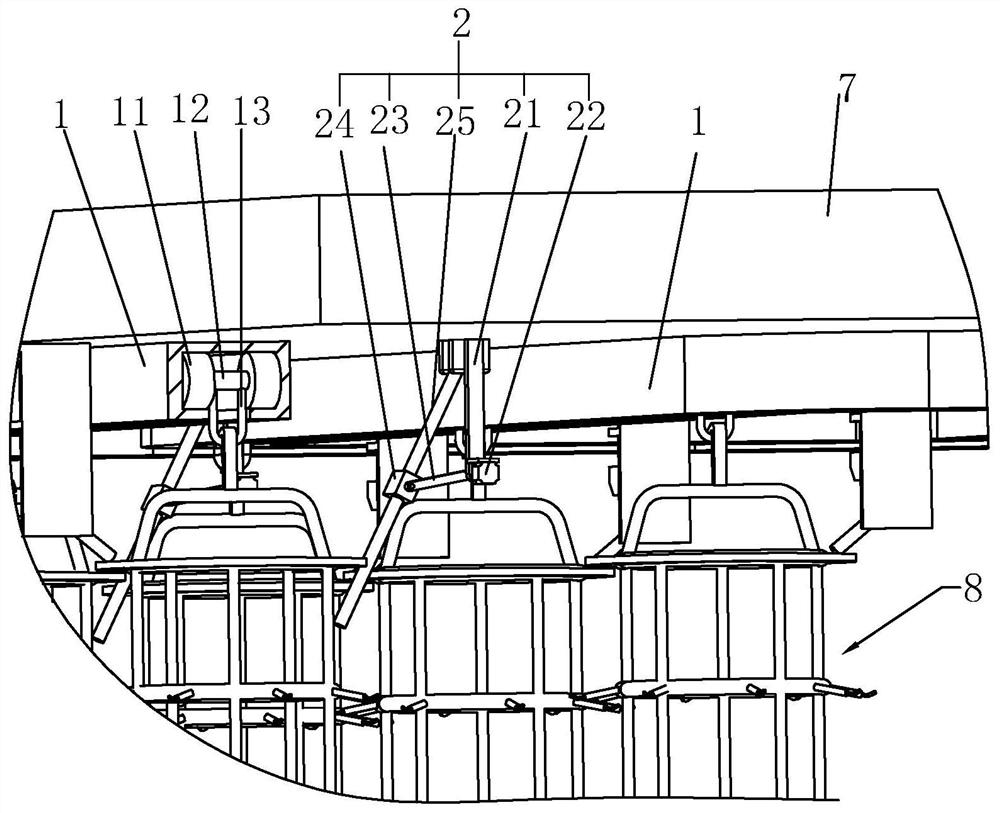

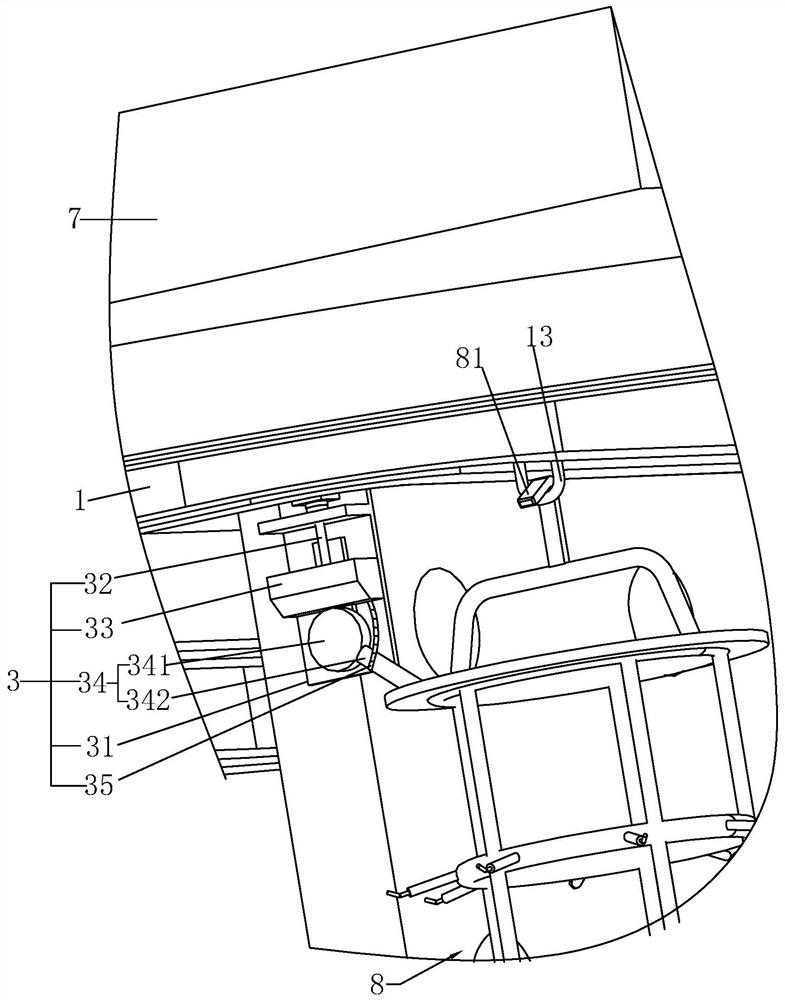

[0066] The following is attached Figure 1-4 And embodiment the present invention is described in further detail.

[0067] The drying method in the electro-zinc-nickel process comprises the following steps:

[0068] (1) Hang the washed product and shake the product to shake off most of the liquid droplets on the surface of the product;

[0069] (2) The wind blows the product to dry the product.

[0070] Step (2) The stroke is hot air, the temperature is 40-70°C, preferably 60°C in this embodiment.

[0071] The product has just been taken out of the water, and there are a large number of droplets on the surface. By shaking, most of the droplets on the surface of the product can be shaken off, which is very conducive to the rapid drying in the later stage; then the product is blown by wind to speed up the evaporation of the droplets on the surface of the product. Further speed up product drying and improve the efficiency of electroplating process. The hot air can speed up th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com