Anti-misoperation starting safe locking mechanism of high-oil-pressure jacking device

A locking mechanism and high oil technology, applied in the direction of valve device, engine components, engine lubrication, etc., can solve the problems of exceeding the rated value, easy damage of the oil pump, high oil pressure, etc., to avoid heat generation, simple structure, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

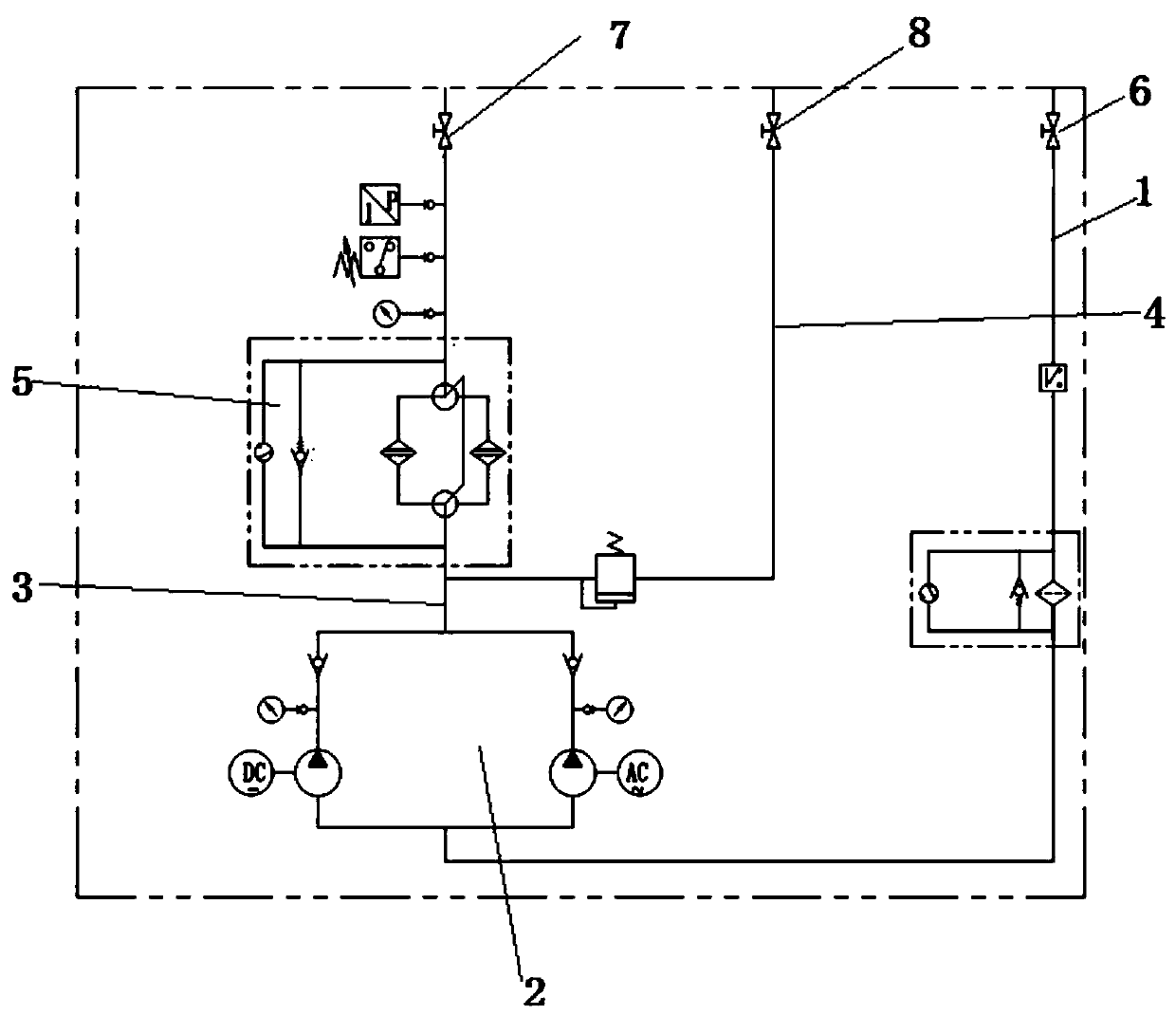

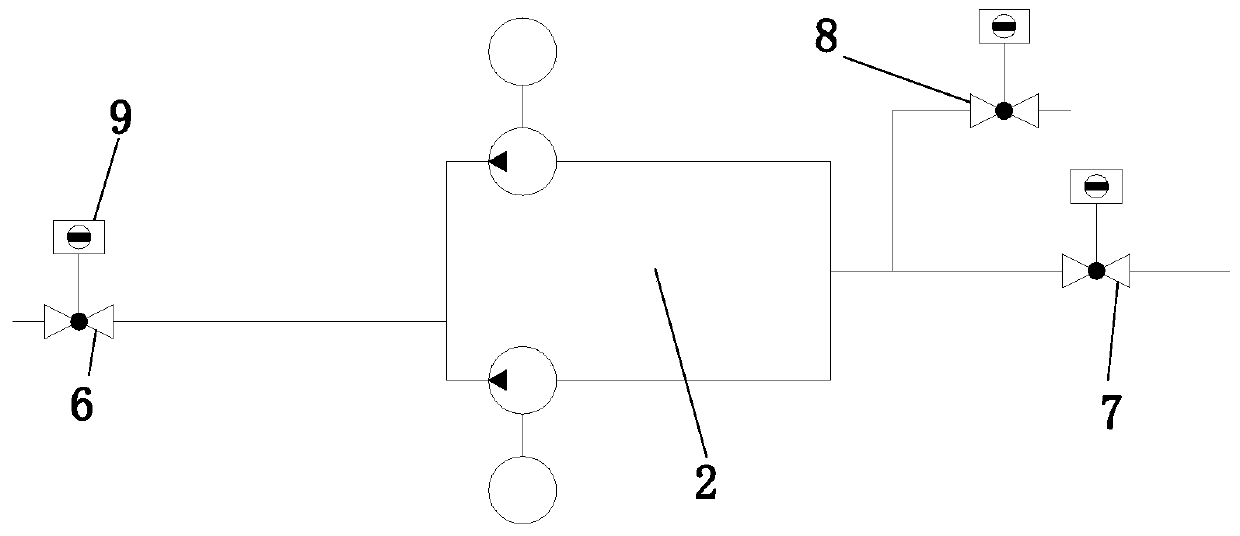

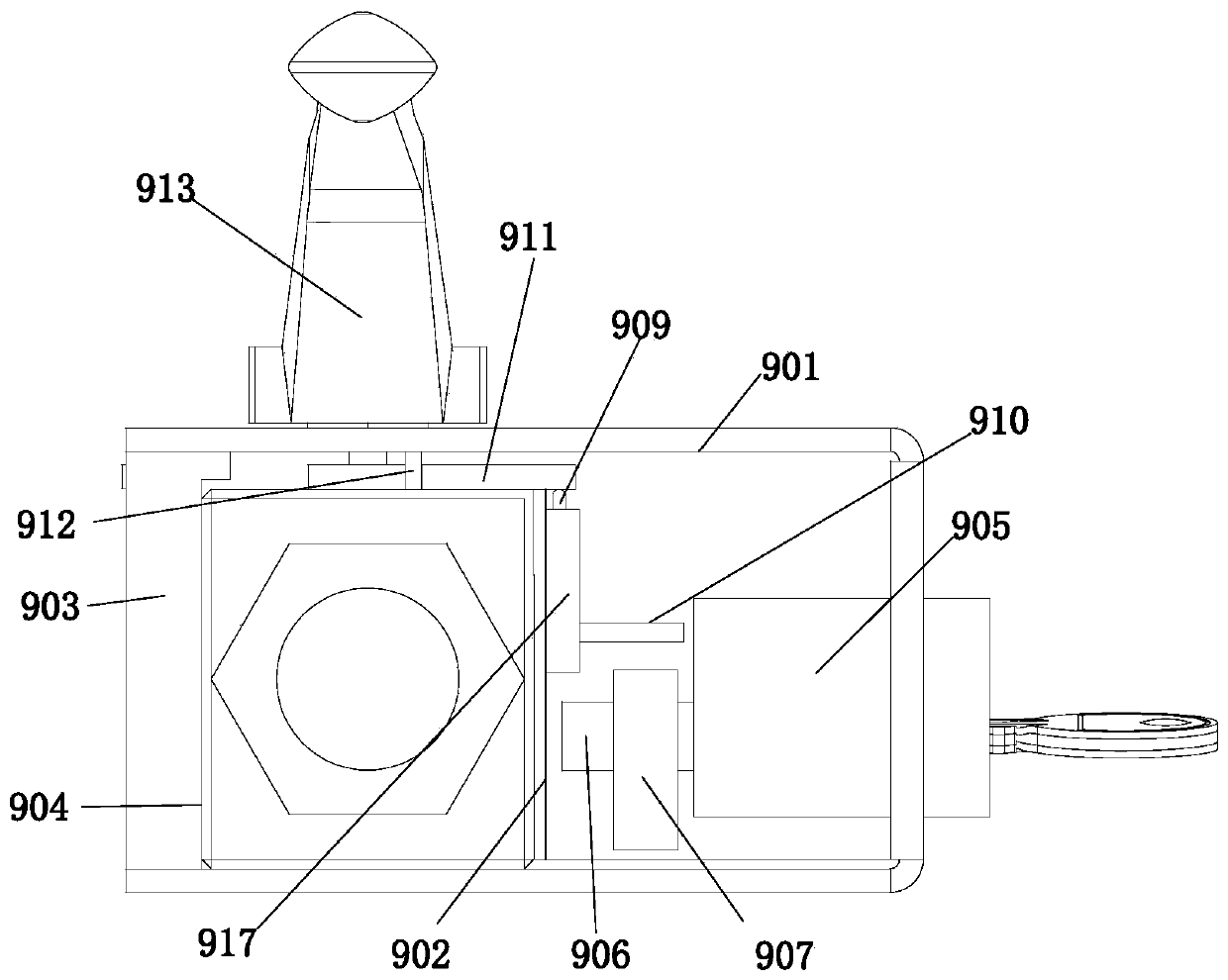

[0023] Example. The high oil pressure jacking device prevents false start safety locking mechanism, which is composed of Figure 1 to Figure 10 As shown, it includes the oil pipe 1, the oil pipe 1 is connected to the high-pressure oil pump 2 and the oil supply pipe 3 in turn, the oil supply pipe 3 is connected to the overflow pipe 4 and the duplex filter 5 in turn, and the overflow pipe 4 is located in the duplex Between the filter 5 and the high-pressure oil pump 2; also includes a control box, the control box is provided with a start-up control circuit connected to the high-pressure oil pump 2, the inlet of the oil pipe 1 is provided with an oil inlet valve 6, and the outlet of the oil supply pipe 3 is provided with a There is an outlet valve 7, and an overflow valve 8 is provided at the outlet e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com