Berth bogie motion control system and working method thereof

A technology of motion control system and working method, applied in the direction of control/adjustment system, non-electric variable control, vehicle position/route/height control, etc., which can solve the problems of cumbersome operation and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

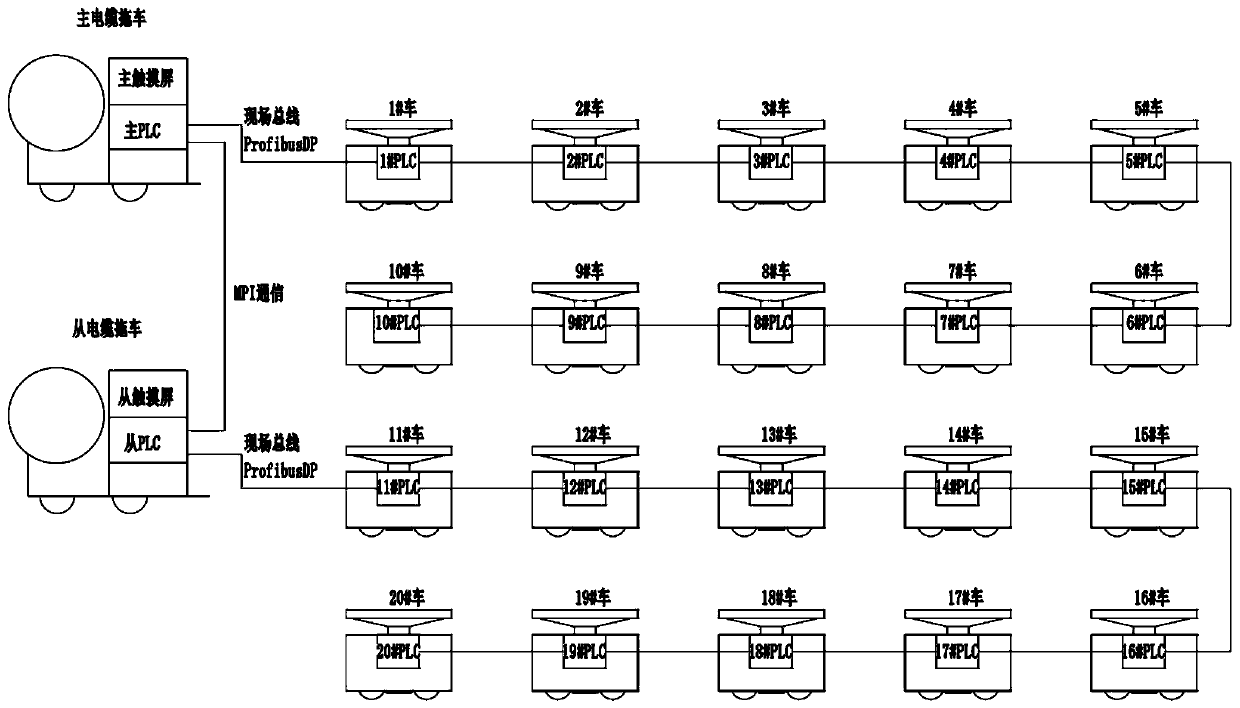

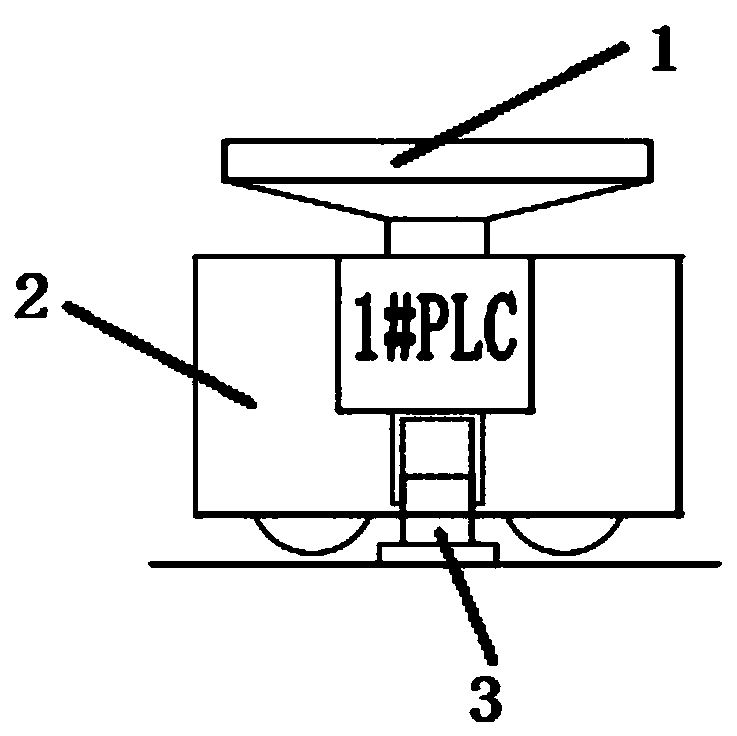

[0040] Such as Figure 1~3 As shown in Fig. 1, a motion control system of a slipway trolley, which includes a slipway trolley group, a master cable trailer and a slave cable trailer.

[0041] In this embodiment, 20 slipway trolleys are used, and the 20 slipway trolleys are named as 1# car to 20# car, 1# car to 10# car is divided into the first group, 11# car to 20# car is divided into the second group, Each slipway trolley is provided with a slipway trolley PLC, and each slipway trolley is provided with a control cabinet, and the control cabinet is suitable for separately controlling the movement of a single slipway trolley.

[0042] The main cable trailer is suitable for centralized control of the movement of the first group of berth trolley groups, the main cable trailer is provided with a main cable trailer PLC, and the second serial communication port of the main cable trailer PLC is connected to the first group of berths. The serial communication port of each slipway tro...

Embodiment 2

[0053] Such as Figure 1~6 As shown, a working method of the motion control system of the slipway trolley, including individual control of a single slipway trolley and centralized control of the slipway trolley group.

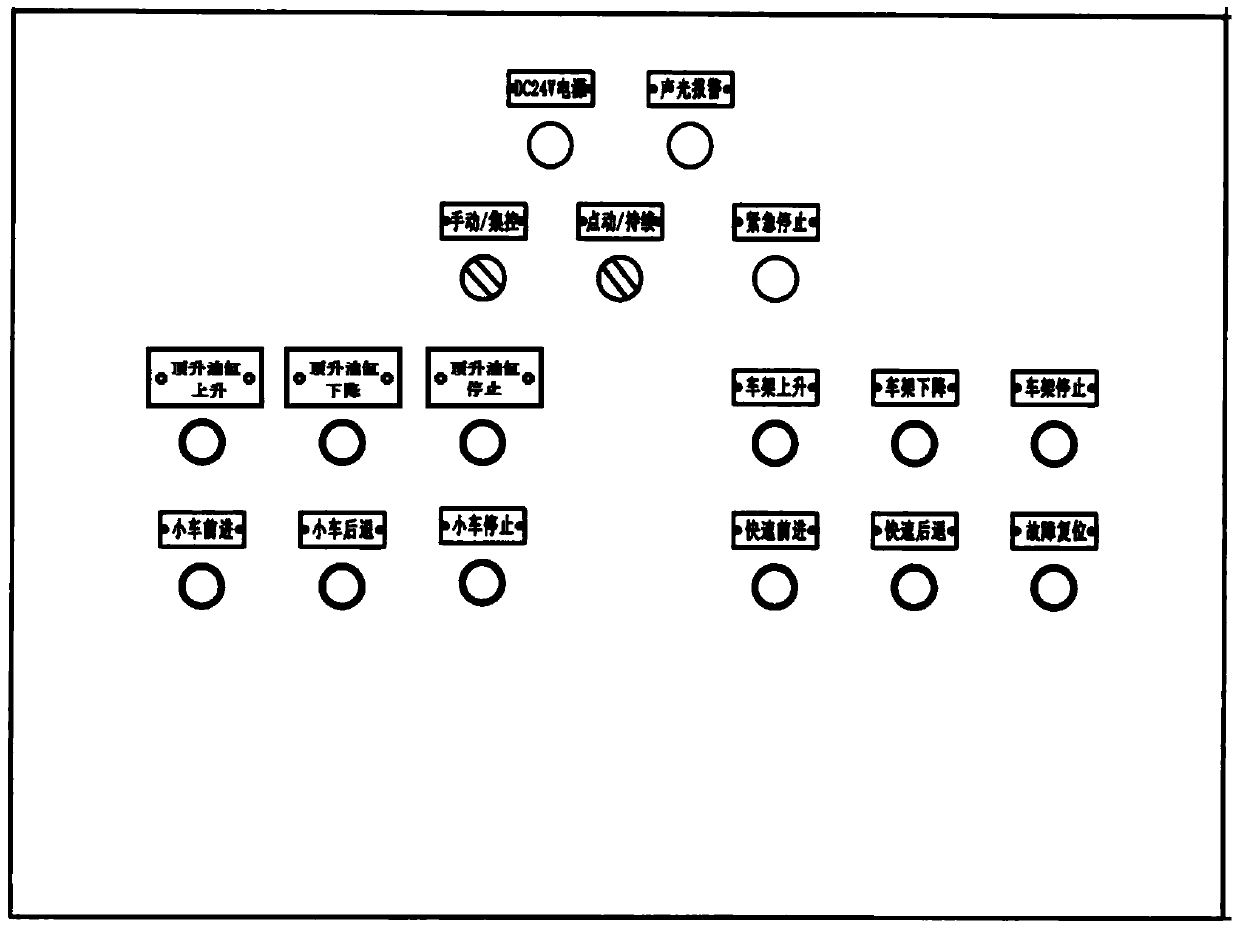

[0054] Further, the steps of the single control of the single berth dolly are:

[0055] Step 1. Switch the control mode knob of the slipway trolley to be controlled separately to the "manual" state;

[0056] Step 2. Press the action button on the control panel of the slipway trolley;

[0057] Step 3, the movement of the slipway trolley;

[0058] Step 4. If the PLC of the slipway trolley has no fault alarm, press the stop button after the slipway trolley moves in place;

[0059] Step 5. If the slipway trolley has not moved in place, continue to repeat steps 3 and 4.

[0060] Further, the control steps after the PLC of the berth trolley has a fault alarm are as follows:

[0061] Step 1. The slipway trolley stops automatically;

[0062] Step 2. If the fault ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com