Automatic sag detection and tension stringing system for overhead transmission line

A technology for overhead transmission lines and wireless communication systems, applied in overhead lines/cable equipment, measuring devices, instruments, etc., can solve problems such as inability to develop, lack of objectivity and consistency of sag data, and high requirements for on-site safety management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

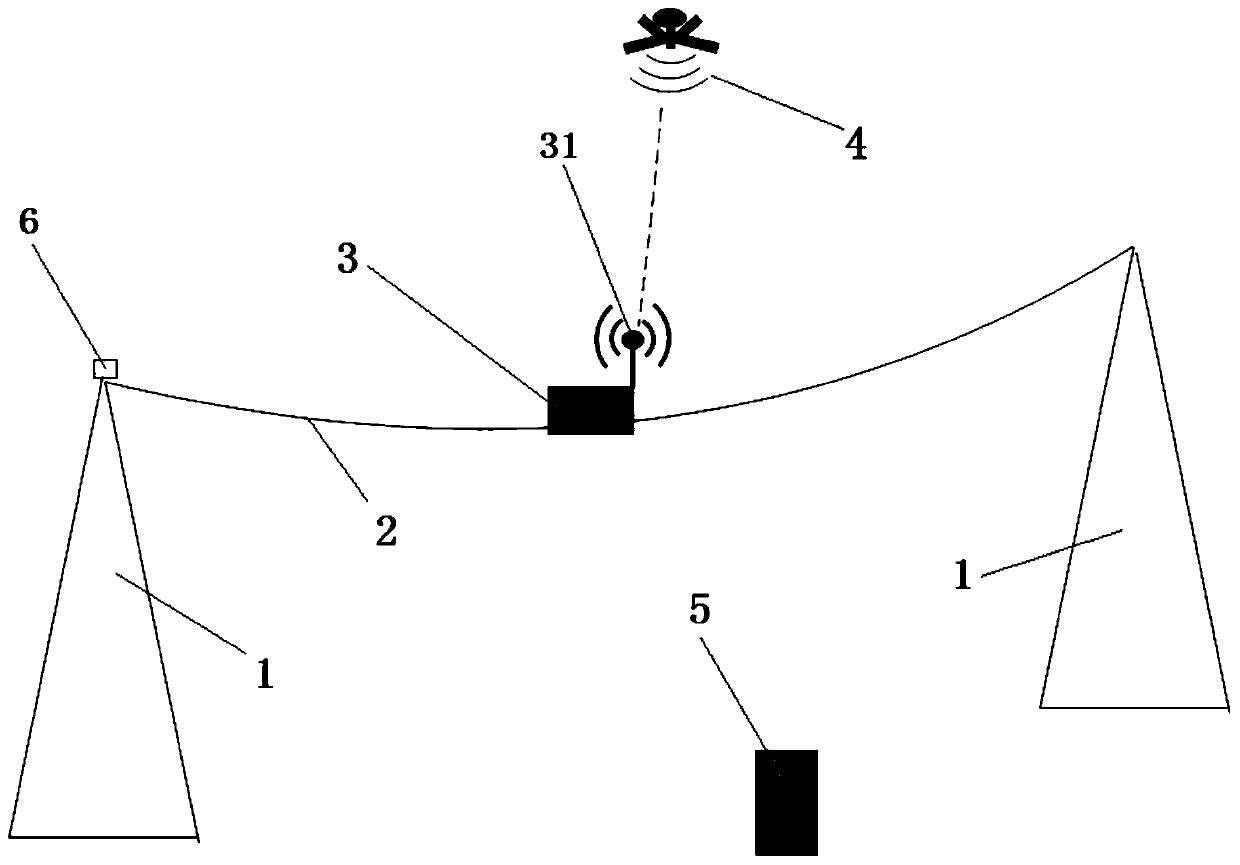

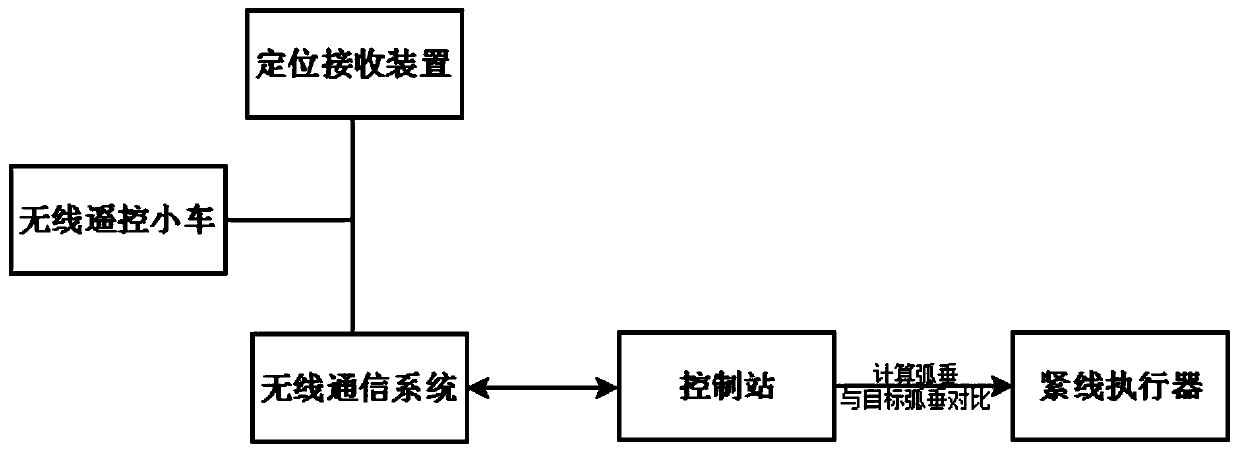

[0027] Such as figure 1 and figure 2 As shown, the overhead transmission line automatic sag detection and line tightening system,

[0028] Including the wireless remote control car 3 that is set on the wire 2 to be tested, the wireless remote control car 3 is provided with a satellite receiving device 31 for receiving the position information sent by the satellite positioning system 4; the wireless remote control car 3 is provided with a wireless communication system; The tight line actuator 6; The control station 5 located on the ground;

[0029] The control station 5 sends a movement command and transmits it to the wireless remote control car 3 through the wireless communication system, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com