Generator saddle assembly and shaft end generator assembly

A technology for carrying saddles and generators, which is applied in the directions of electric components, electrical components, casings/covers/supports, etc., and can solve the problems of easily damaged railway generators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

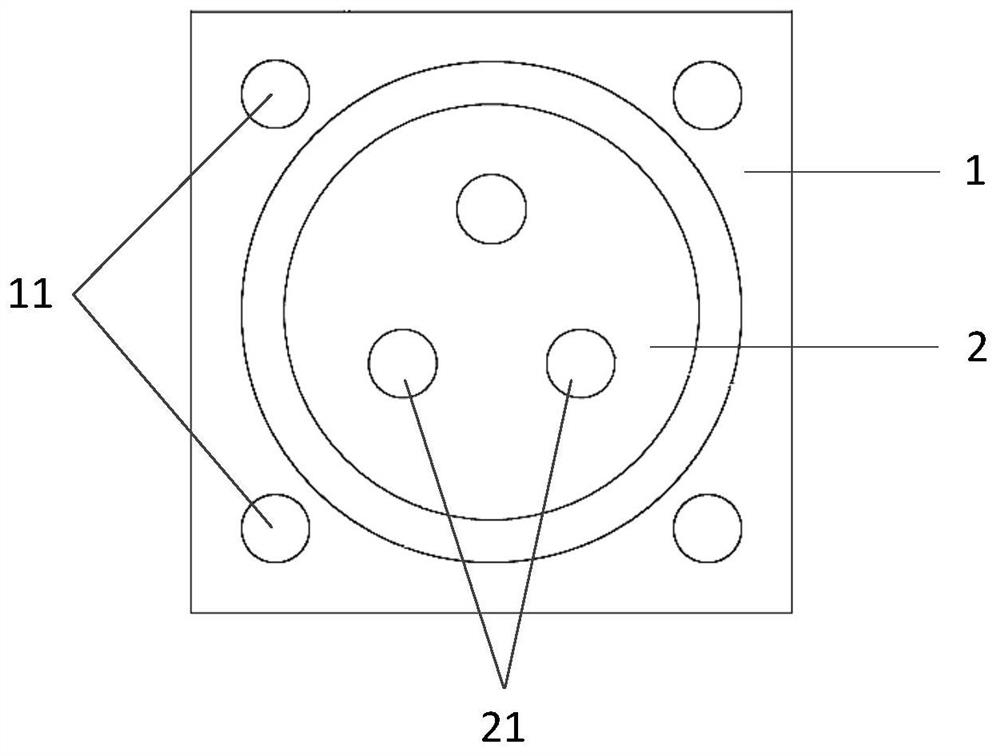

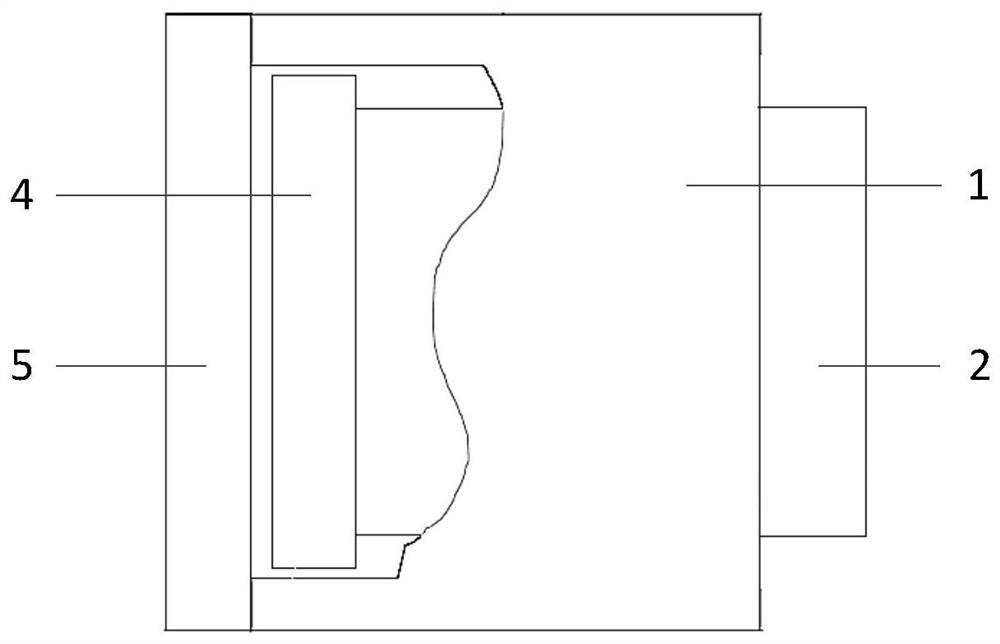

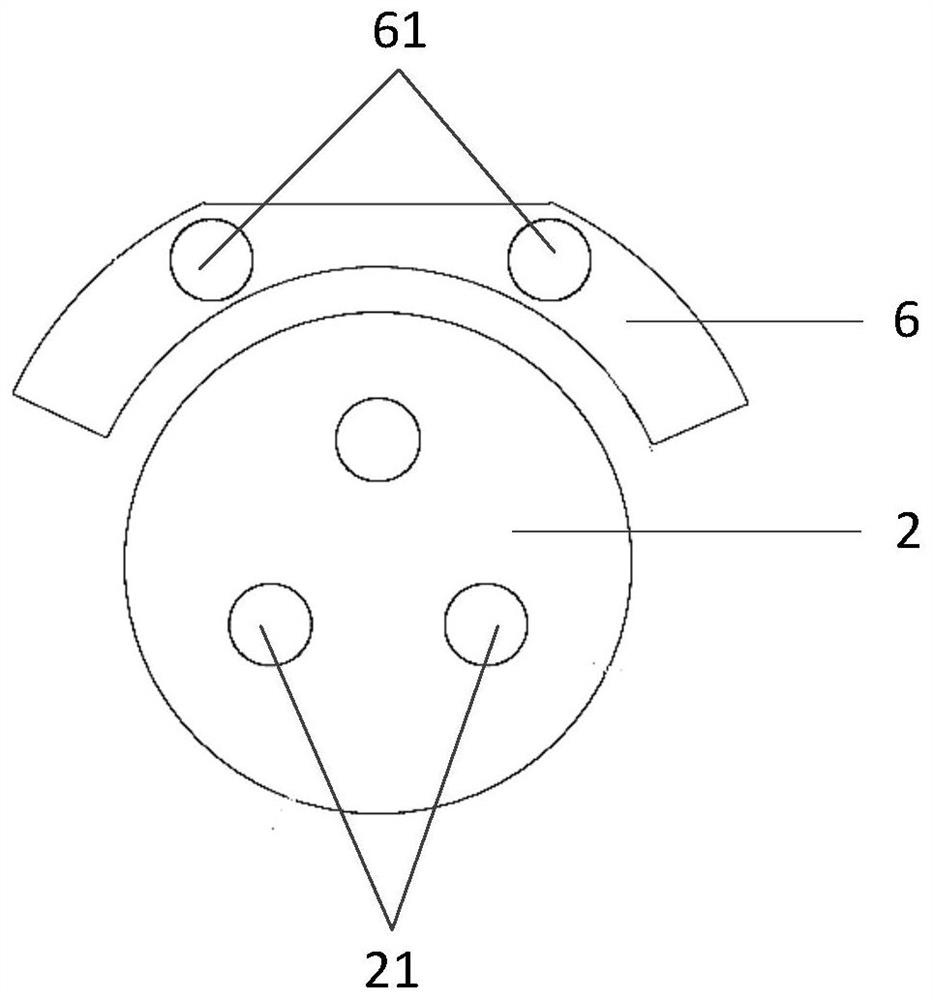

[0094] like Figure 3A and 3B As shown, the shaft end generator assembly of this embodiment has a load saddle assembly. The saddle assembly has a split structure comprising: i) a first portion 610 obtained by modifying a conventional saddle, wherein the first portion 610 can pass through a groove 614 formed thereon (see Figure 4C ) to a car truck, eg, in a similar manner to a conventional saddle; and ii) a second portion 620 connected to the first portion 610 via screws 630 . The first part 610 and the second part 620 together form a base for mounting the stator of the shaft end generator.

[0095] In this embodiment, the first portion 610 is the upper portion and can support the bogie payload, and the second portion is the underside portion and does not support the bogie payload. However, the present disclosure is not limited thereto, and the first part 610 and the second part 620 may also be a right part and a left part, respectively. The first and second portions 610, ...

no. 2 approach

[0117] Figure 5A and 5B A shaft end generator assembly in a second embodiment of the present disclosure is schematically shown. exist Figure 5A and 5B , some components of the generator assembly are omitted to clearly show the structure.

[0118] This embodiment has a similar concept to the first embodiment, and only the differences therebetween will be described below.

[0119] like Figure 5A and 5B As shown, the saddle assembly has a split structure comprising: i) a first part 610 obtained by modifying a conventional saddle, wherein the first part 610 can be mounted to the car truck through a groove 614 formed thereon, and the first part 610 is A portion 610 supports the bogie payload; and ii) a second portion 620 connected to the first portion 610, wherein the second portion 620 does not support the bogie payload. The first part 610 and the second part 620 have similar structures and can be replaced with each other.

[0120] Instead of surrounding the shaft 200 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com