Efficient and safe logistics supporting device

A support device and safe technology, applied in display stands, display hangers, display shelves, etc., can solve the problems of low structural strength, poor applicability, troublesome storage, etc., and achieve the effect of good load stability, high adaptability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

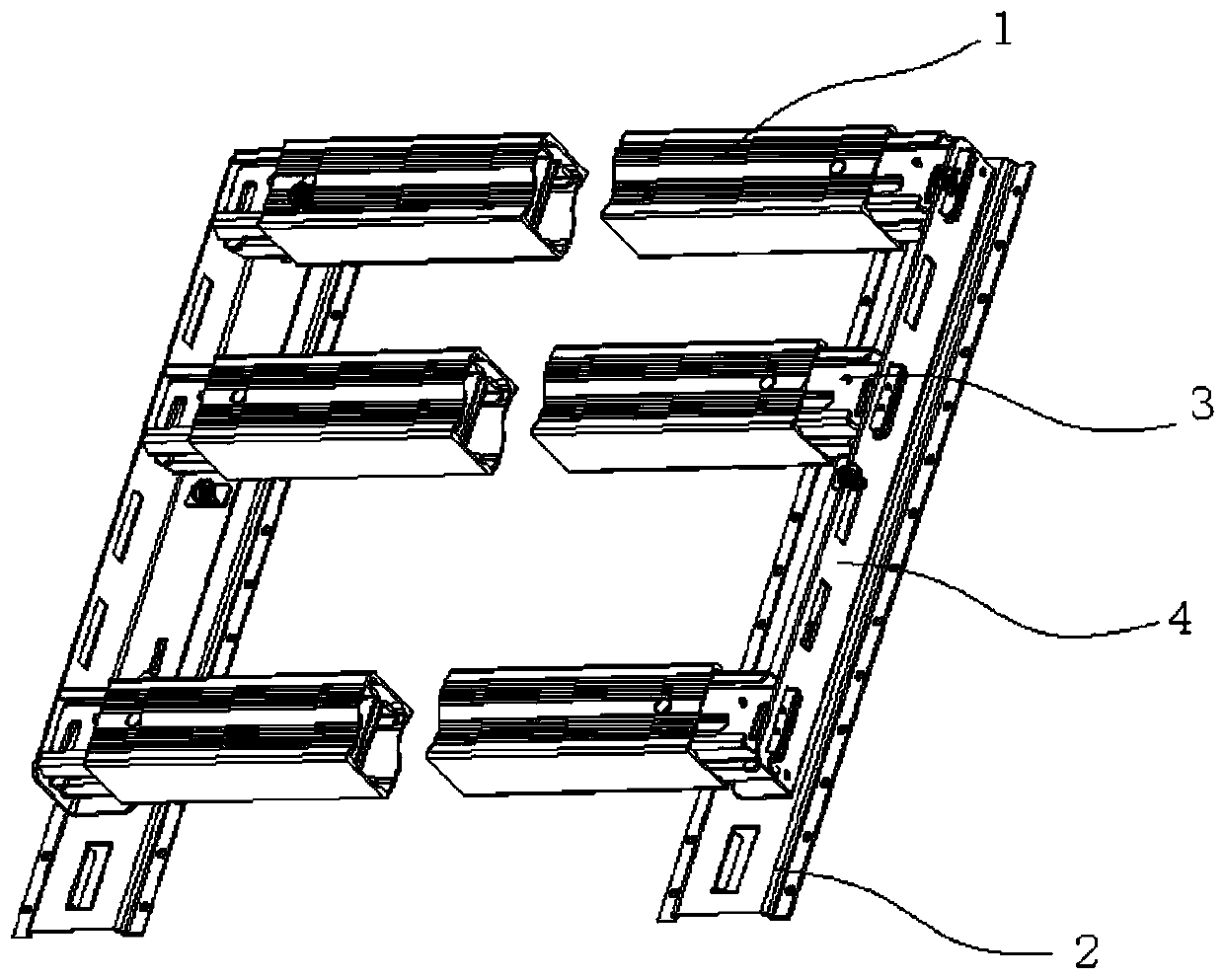

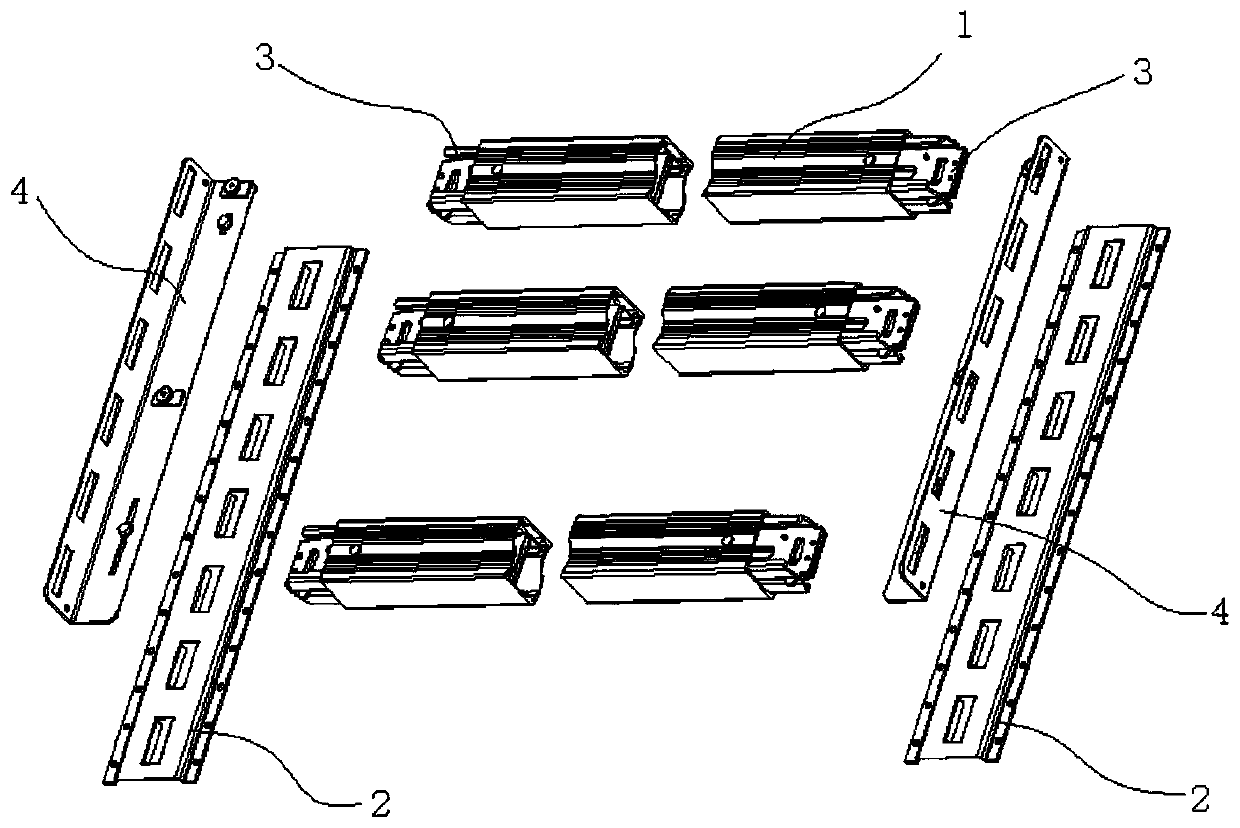

[0029] An efficient and safe logistics support device, comprising support beams 1 and connecting guide rails 2, characterized in that the number of the support beams 1 is multiple, and telescopic connecting joints 3 are arranged symmetrically at both ends, and the connecting guide rails 2 A detachable bracket panel 4 is fixed on the top, and the support beam 1 is connected to the bracket panel 4 through a telescopic connection joint 3, and then connected to the connecting rails 2, and is telescopically arranged between the connecting rails 2;

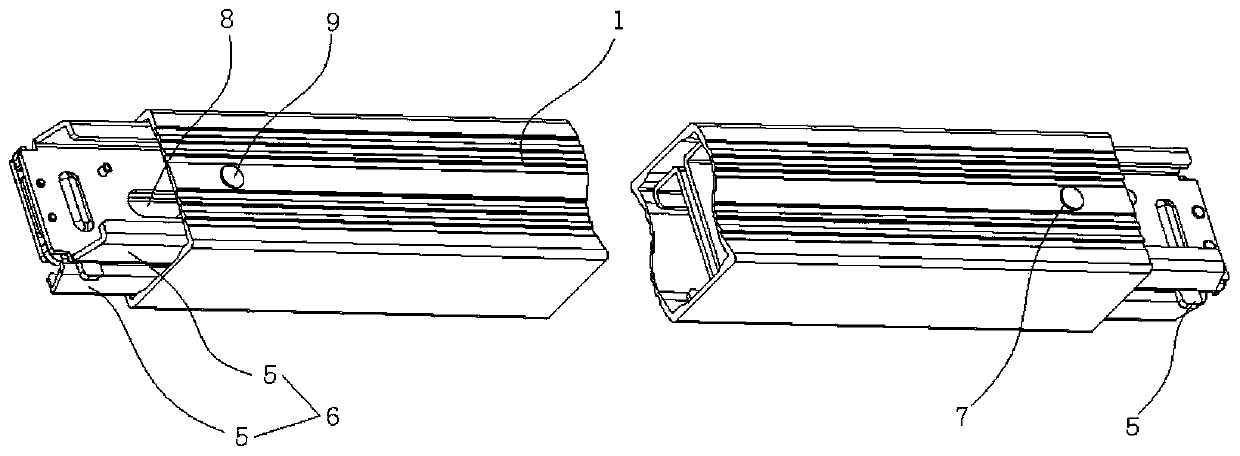

[0030] The supporting beam 1 is connected in the middle, and one end of the connecting joint 3 is slidably arranged in the end of the supporting beam 1, and the other end is provided with a joint assembly 5, and the connecting joint 3 includes two joint plates 6, and the two joint plates 6 are symmetrically arranged, connected by riveting, and a gap is reserved through the boss, and the joint assembly 5 is arranged in the gap between the...

Embodiment 2

[0039] In this embodiment, the connection panel 19 is provided with a first connection hole 22, a second connection hole 23 and a third connection hole 25, and the connection guide rail 2 is provided with a plurality of fourth connection holes 26, and the plurality of connection holes The fourth connection holes 26 are evenly distributed at equal intervals along the connection guide rail 2, the first connection holes 22 and the second connection holes 23 are located at both ends of the connection panel 19, and the third connection holes 25 are located at the first connection Between the hole 22 and the second connecting hole 23, the first connecting hole 22, the third connecting hole 25 and the fourth connecting hole 26 are all waist-shaped holes or slot-shaped holes, the second connecting hole 23 is a round hole, and the first connecting hole 23 is a circular hole. The hole 22, the second connecting hole 23 and the third connecting hole 25 are respectively provided with a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com