Recovery and crushing treatment device of computer circuit boards

A technology for processing equipment and circuit boards, which is applied in grain processing, magnetic separation, solid separation, etc., can solve problems such as easy blockage, and achieve the effect of preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

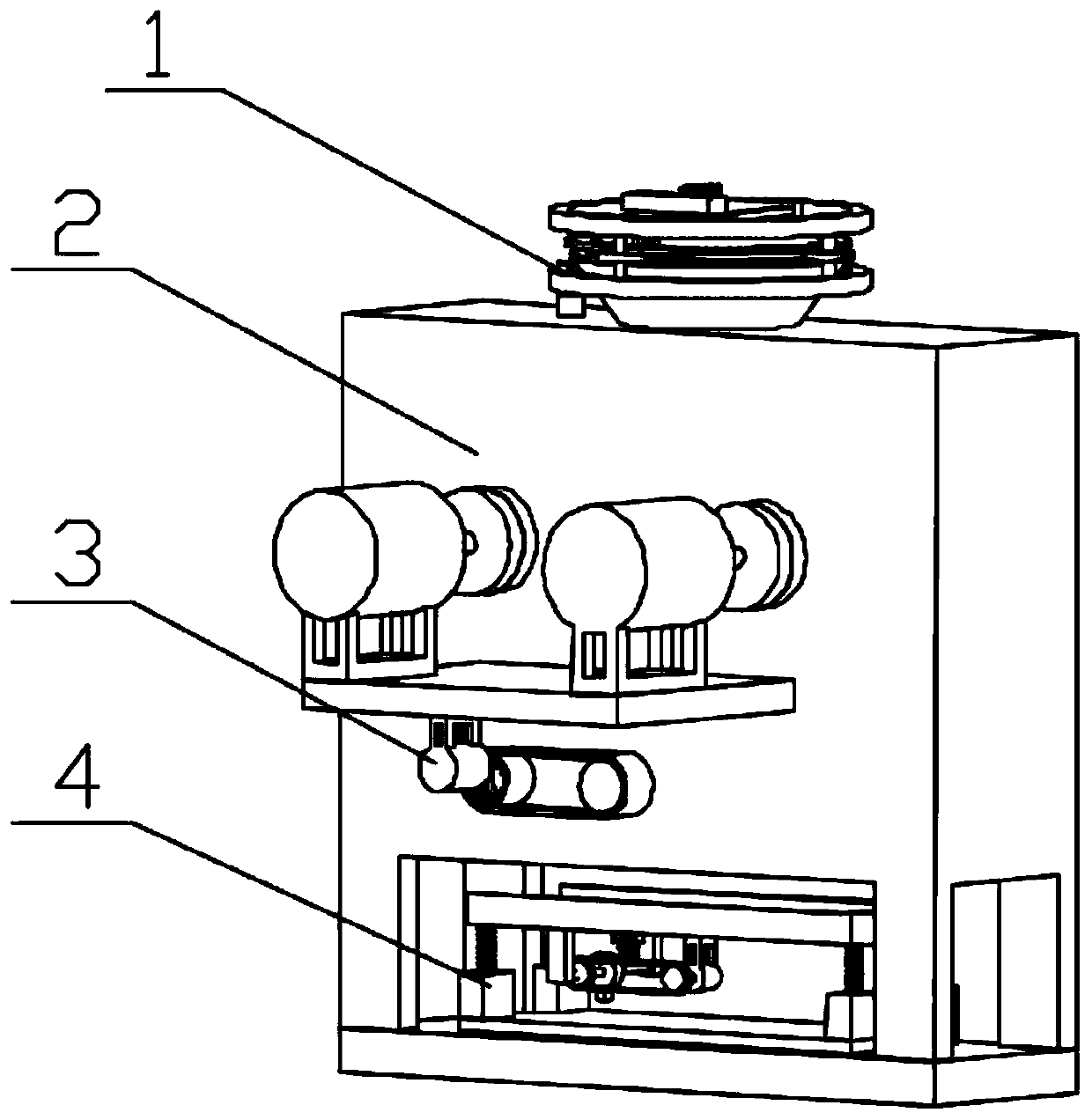

[0042] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 , Figure 25 , Figure 26 Describe this embodiment, the present invention relates to a kind of crushing equipment, more specifically a kind of computer circuit board recycling and crushing processing equipment, including anti-blocking mechanism 1, crushing mechanism 2, iron removal mechanism 3, feeding mechanism 4, the equipment can To prevent material blocking, the equipment can firmly fix the scraper mechanism, the equipment can crush the circuit board, the equipment can absorb iron impurities, the equipment can feed materials better, and the equipment can recover iron impurities.

[0043] The anti-blocking mechanism 1 is connected with t...

specific Embodiment approach 2

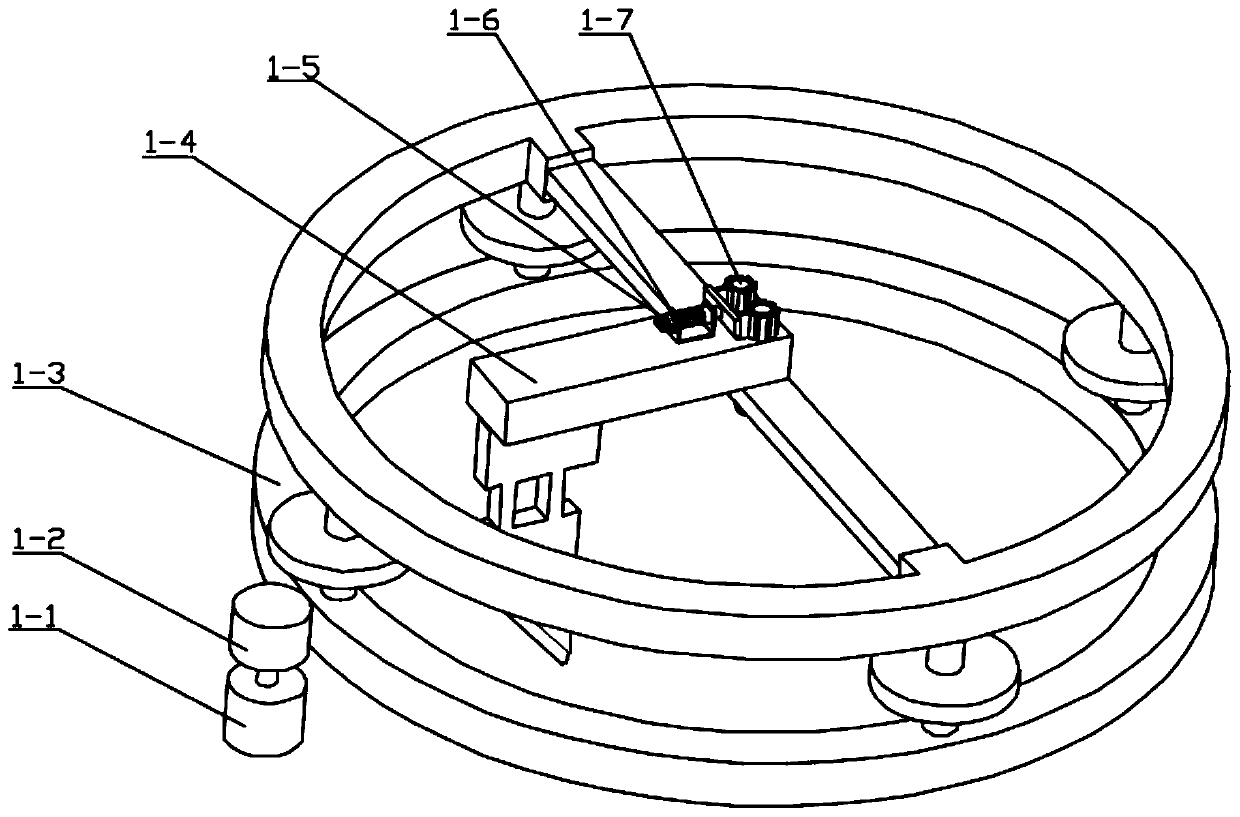

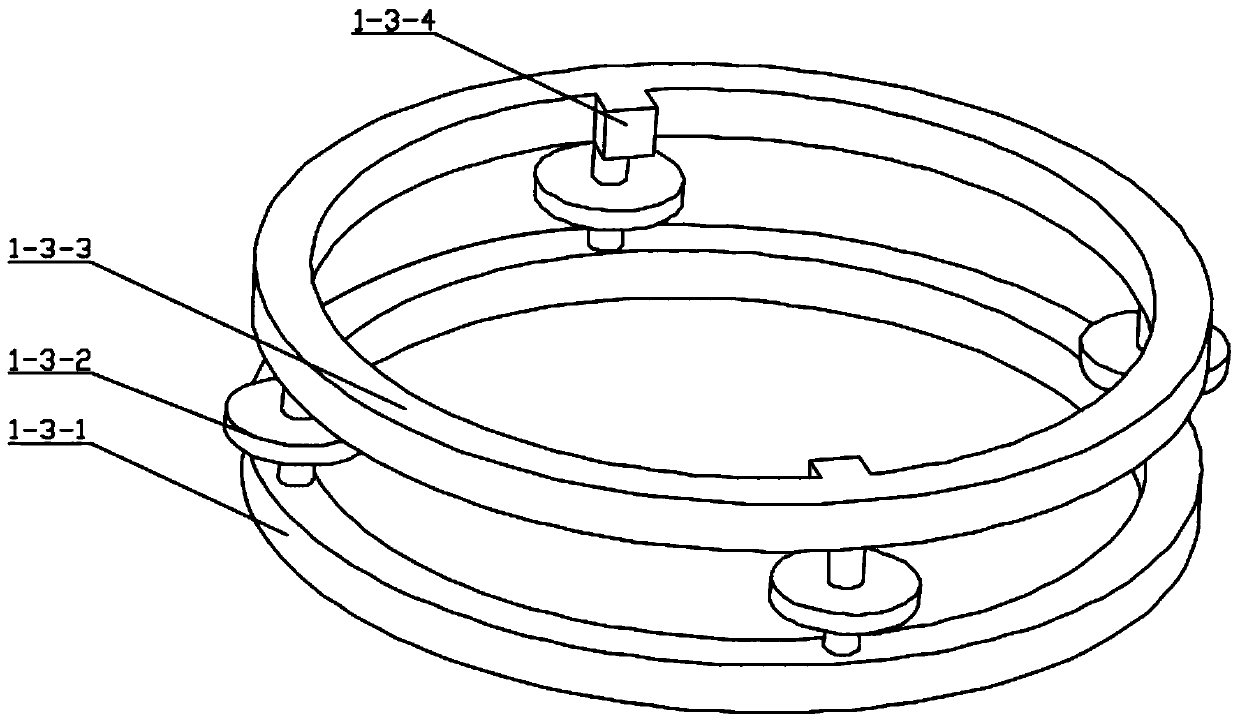

[0045] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 , Figure 25 , Figure 26 Describe this embodiment, this embodiment will further explain Embodiment 1, the anti-blocking mechanism 1 includes an anti-blocking motor 1-1, a motor gear 1-2, a pulley frame mechanism 1-3, and a scraper mechanism 1-4 , Pulling limit mechanism 1-5, frame body mechanism 1-6, limit bolt group mechanism 1-7, anti-blocking motor 1-1 is connected with motor gear 1-2, motor gear 1-2 is connected with pulley frame mechanism 1- 3-phase meshing, the pulley frame mechanism 1-3 is connected with the scraper mechanism 1-4, the scraper mechanism 1-4 is connected with the pulling limit mechanism 1-5, and the pulling limit mech...

specific Embodiment approach 3

[0047] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 , Figure 25 , Figure 26Describe this embodiment, this embodiment will further explain Embodiment 1, the crushing mechanism 2 includes a fuselage mechanism 2-1, a crushing actuator 2-2, and the fuselage mechanism 2-1 is connected to the crushing actuator 2-2 ; Fuselage mechanism 2-1 includes feed hopper 2-1-1, matching groove 2-1-2, fuselage 2-1-3, bearing block 2-1-4, support plate 2-1-5, bearing Seat I2-1-6, base 2-1-7, feed inlet 2-1-8, matching groove 2-1-2 is opened on feed hopper 2-1-1, feed hopper 2-1-1 It is connected with the fuselage 2-1-3, the bearing seat 2-1-4 is connected with the fuselage 2-1-3, the support plate 2-1-5 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com