Integrated pot and processing technology thereof

A processing technology, an integrated technology, applied in the field of integrated pots and its processing technology, can solve the problems of easy accumulation of dirt, uneven connection between the spout 1 and the pot body 11, inconvenient cleaning, etc., and achieve long service life and high connection strength , easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

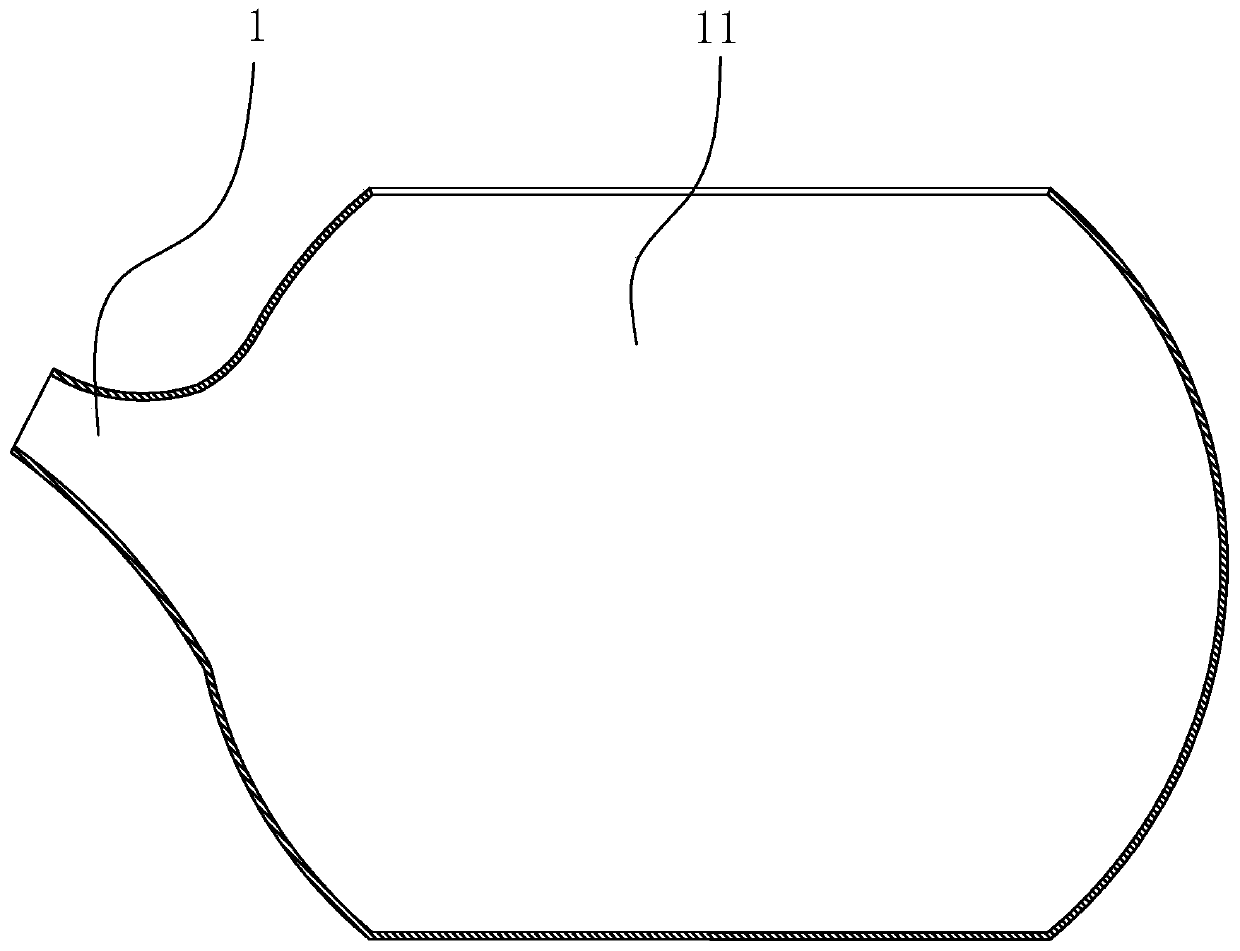

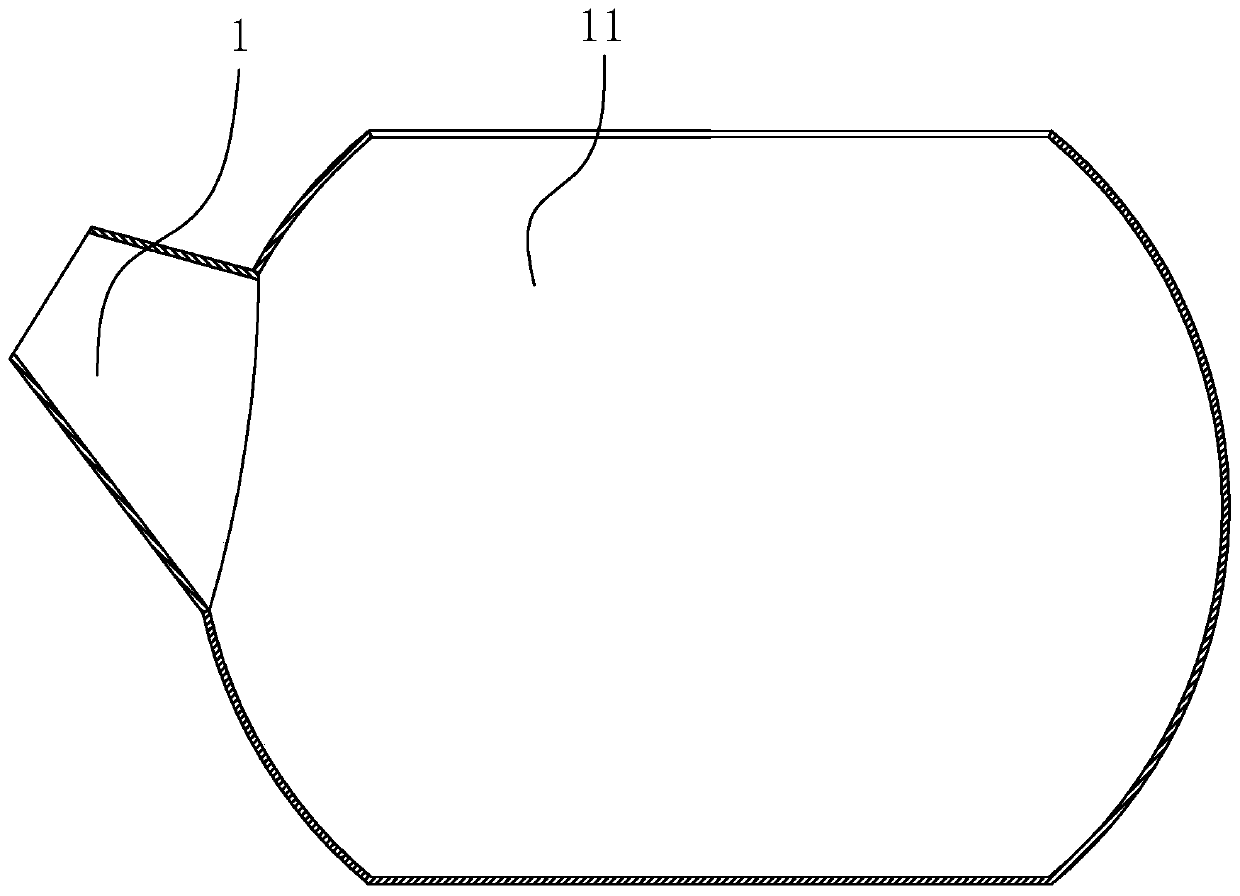

[0040] An integrated pot, referring to Figure X, which includes a connected spout 1 and a pot body 11, the spout 1 and the pot body 11 are integrally formed, and the connection between the spout 1 and the pot body 11 is an arc surface.

[0041] The working principle is as follows: the spout 1 and the pot body 11 are integrally formed, which can make the connection between the spout 1 and the pot body 11 smoother than welding, so that dirt is not easy to hide in the joint between the spout 1 and the pot body 11, And it is easy to clean. In addition, the welded spout 1 is prone to falling off, and the integrally formed spout 1 and the pot body 11 have higher connection strength, and have a longer service life than the welded spout 1 .

Embodiment 2

[0043] A processing technology for an integrated pot, comprising the following steps:

[0044] S1. Prepare the metal sheet. The metal sheet is preferably disc-shaped. The thickness and diameter of the sheet metal are determined according to the required size of the kettle body.

[0045] S2. Scratch the metal sheet with a compass pen to mark the position and diameter of the bottom wall of the pot. Use a musket to burn the metal sheet along the marking line until it turns red. After natural cooling, place it under the metal sheet. Place a disk with the same specifications as the bottom wall of the pot body, and make the disk coincide with the marking line. The outer side of the disc is covered with an elastic layer, the elastic layer is preferably made of rubber, and the thickness of the elastic layer is 0.1 mm. Afterwards, along the marking line on the bottom wall of the pot body, use a hard hammer to knock the surroundings of the metal sheet, so that the surroundings of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com