Wall surface grinding device for building decoration

A technology for building decoration and walking device, which is applied in the direction of grinding drive device, building, building structure, etc., can solve the problems of long construction period and low work efficiency, and achieve the effect of shortening construction period, improving work efficiency, and changing the spraying area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] specific implementation plan

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

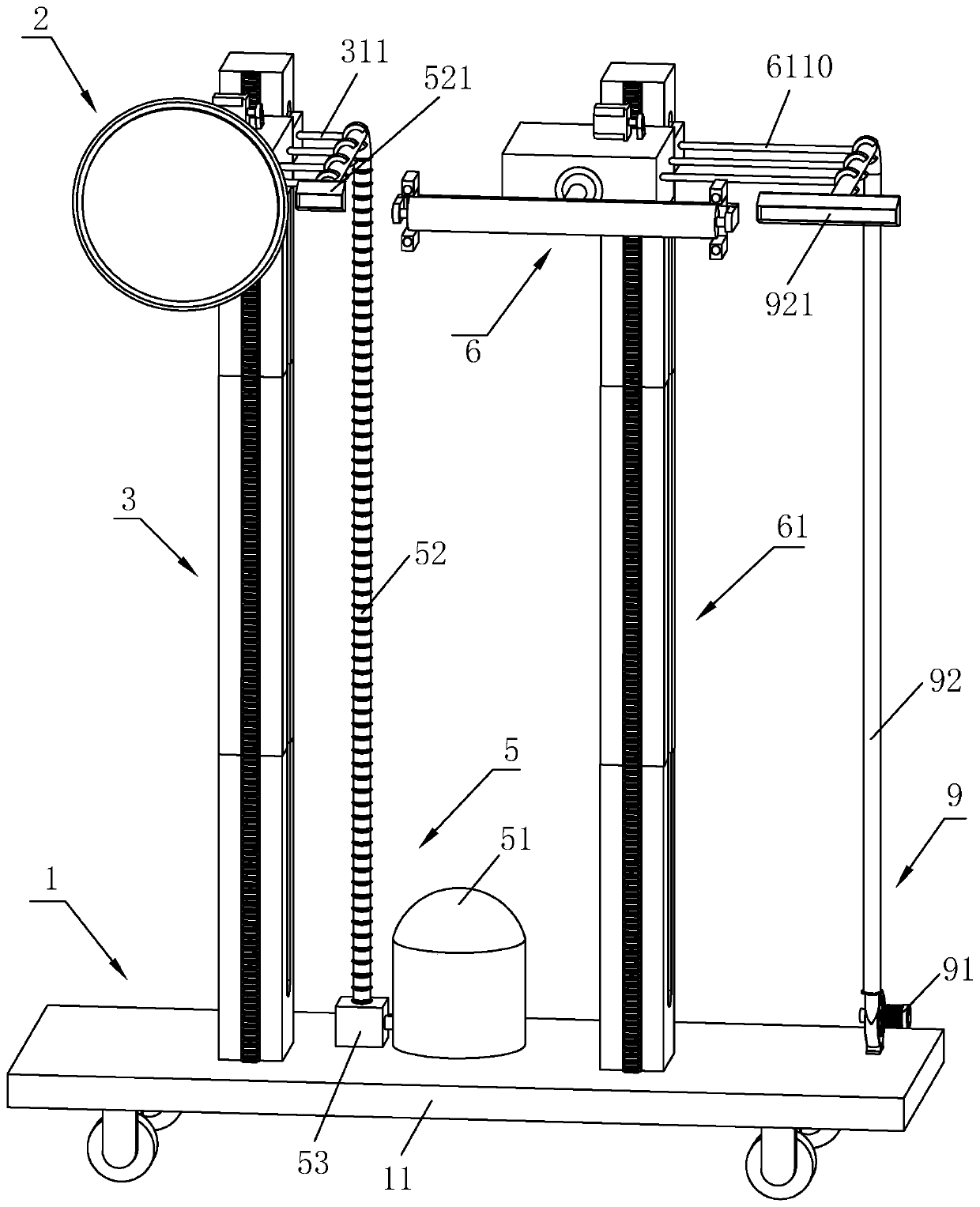

[0040] A wall grinding device for architectural decoration, such as figure 1 As shown, it includes a traveling device 1, a grinding mechanism 2 installed on the traveling device 1 and a spraying device for spraying walls. Wherein, the running device 1 is a vehicle body 11 that can move on the ground. The car body 11 is provided with a first elevating frame 3 for supporting the grinding mechanism 2, and the first elevating frame 3 drives the grinding mechanism 2 to go up and down, and the car body 11 moves laterally to drive the grinding mechanism 2 to move laterally, thereby realizing the change of the grinding mechanism 2. Sand the area.

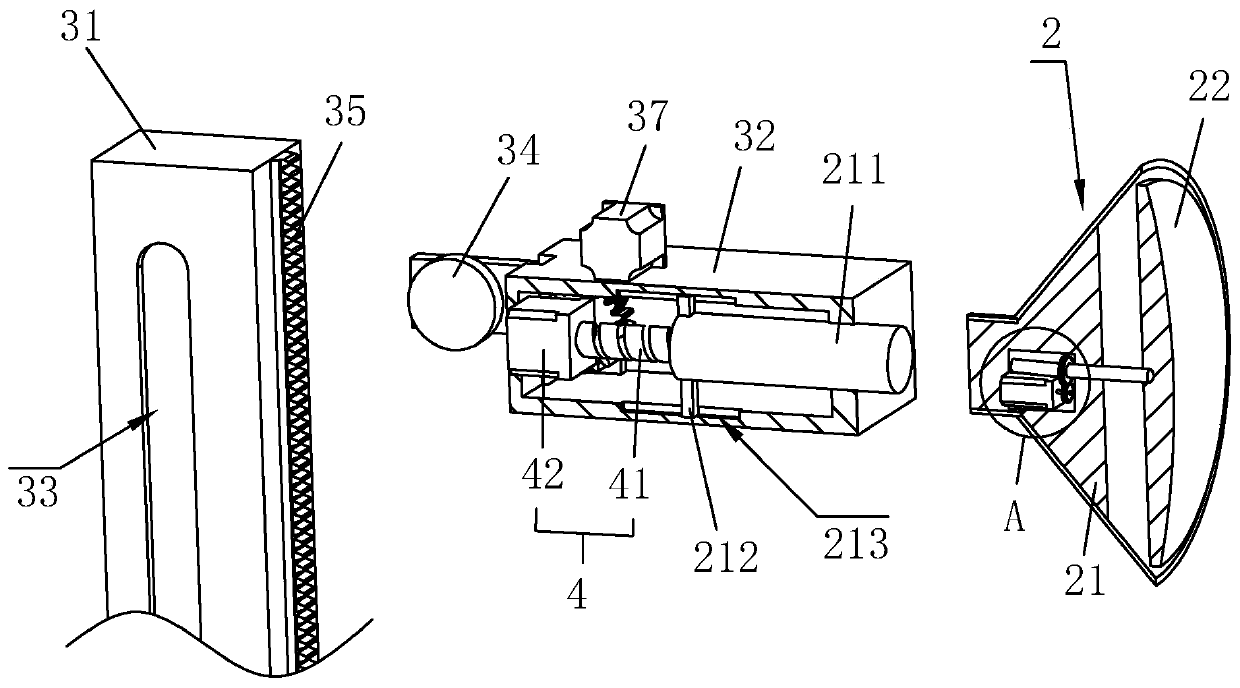

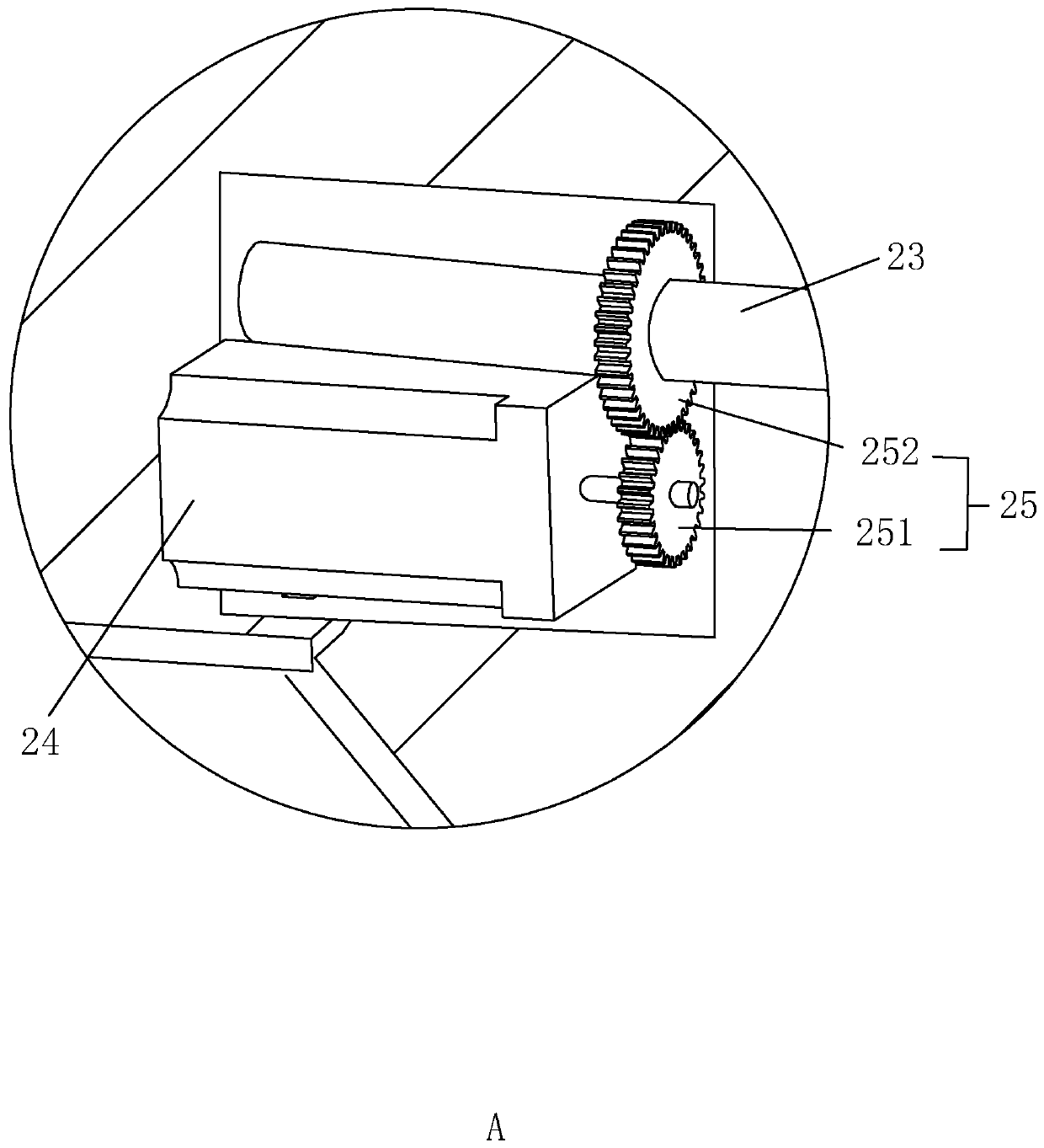

[0041] Specifically, such as figure 1 and figure 2 As shown, the first lifting frame 3 includes a first column 31 fixedly installed on the vehicle body 11 and a first lifting box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com