A hand-held grinder

A kind of grinding machine and hand-held technology, which is applied in the direction of grinding frame, portable grinding machine, grinding machine tool parts, etc., can solve the problems of operator fatigue, solder joint grinding quality reduction, etc., so as to change the grinding area and ensure grinding Depth and precision, the effect of precise grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

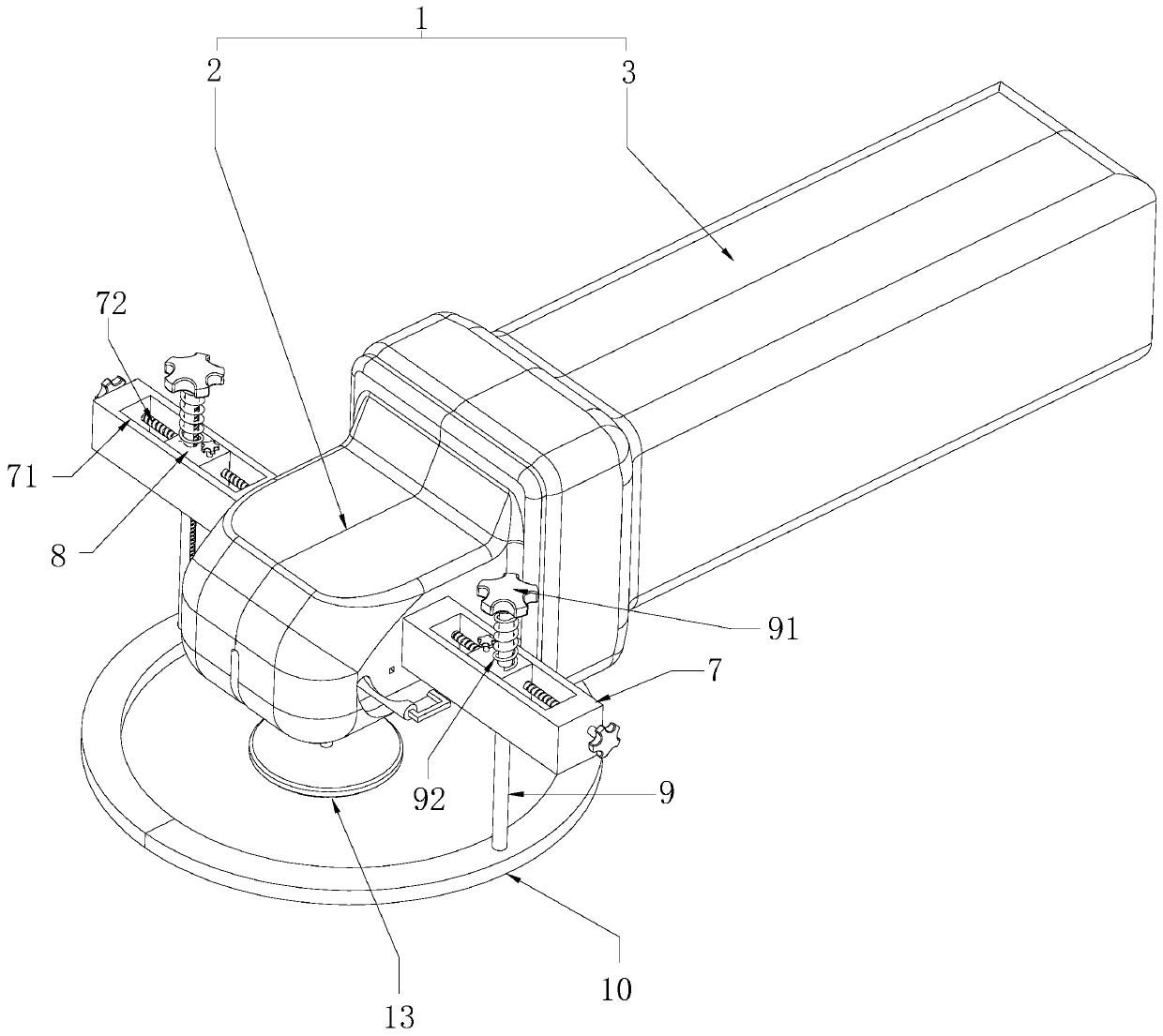

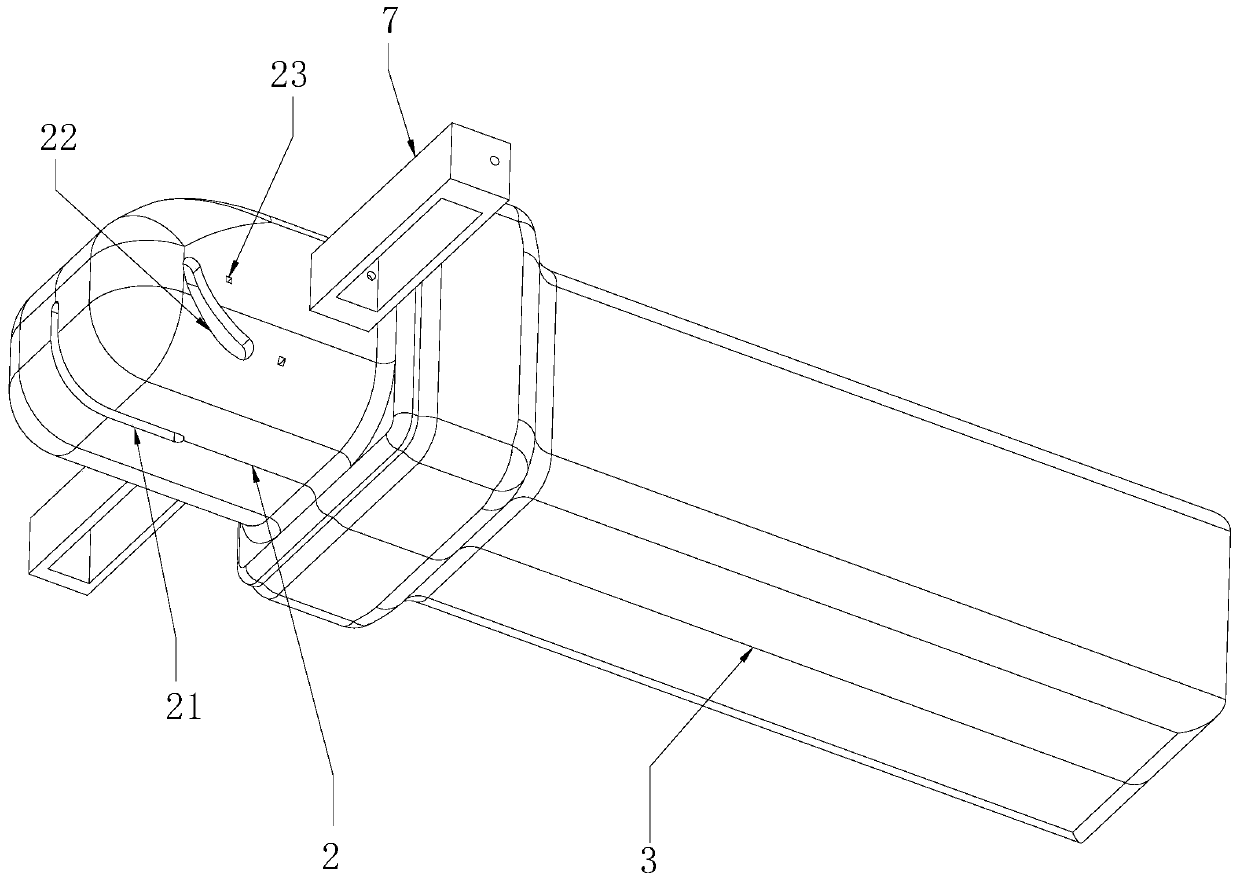

[0034] Such as figure 1 As shown, a hand-held grinding machine includes a frame 1 and a grinding wheel 13. The frame 1 includes a hand-held part 3 and a mounting part 2. A motor 4 is arranged in the hand-held part 3, and a drive shaft is provided at the rotating end of the motor 4. 41, the grinding wheel shaft 5 and the transmission gear set for connecting the grinding wheel shaft 5 and the driving shaft 41 are rotated in the installation part 2, and the grinding wheel 13 is coaxially fixed on the grinding wheel shaft 5, the motor 4 is started, and the transmission gear is used to The group makes the grinding wheel shaft 5 drive the grinding wheel 13 to rotate, and the lower end surface of the grinding wheel 13 is close to the welding spot on the workpiece, so as to realize the purpose of grinding the welding spot.

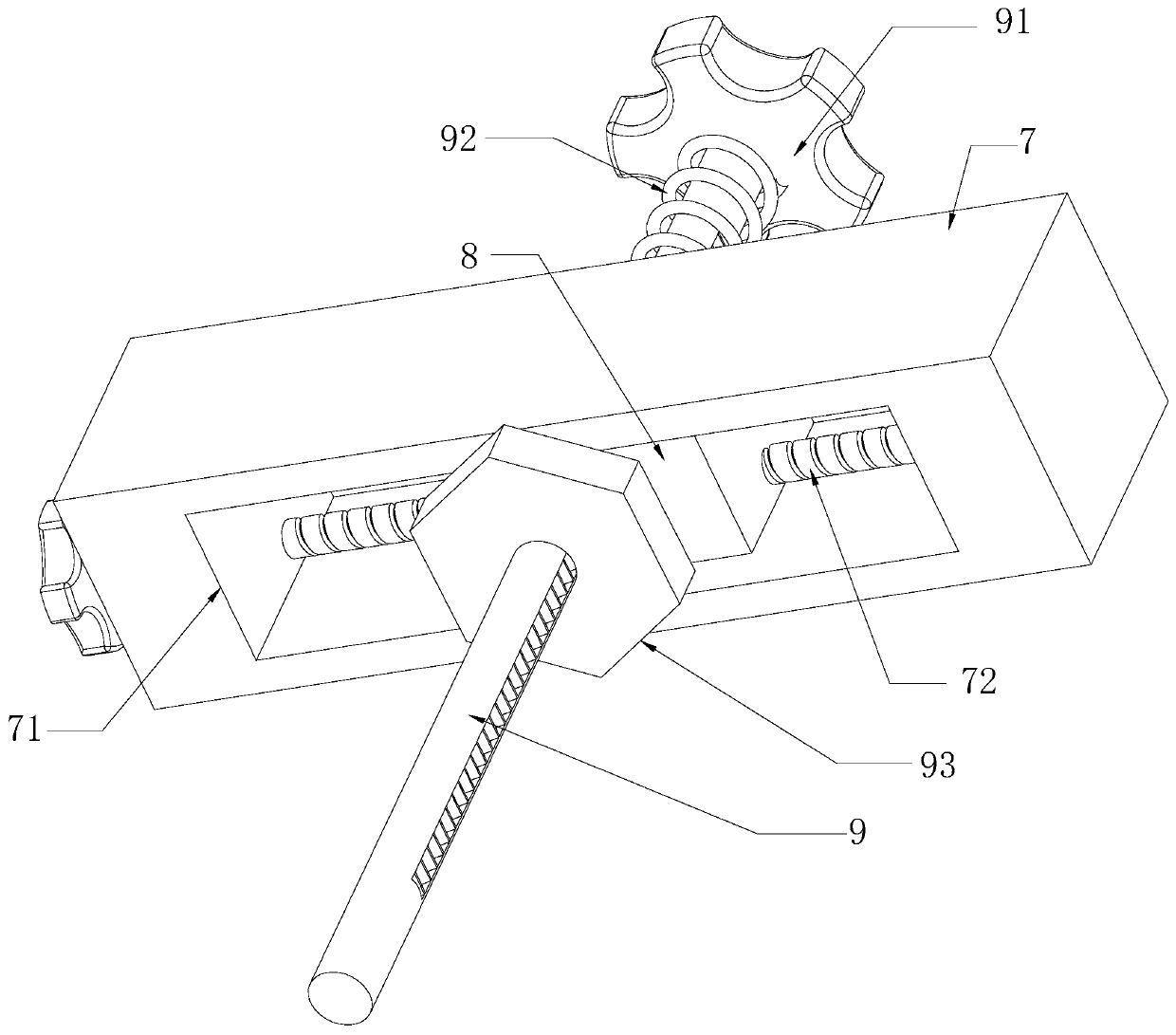

[0035] Such as figure 1 and figure 2 As shown, mounting seats 7 are arranged on both sides of the width direction of the mounting part 2, and the mounting seat...

Embodiment 2

[0046] The difference between embodiment two and embodiment one is:

[0047] Such as Figure 5 As shown, a rack 94 is provided on the lifting rod 9 and along its vertical direction, a gear 11 is rotated on the slide 8, and the gear 11 is engaged with the rack 94, and a gear 94 is rotated on the slide 8 Screw mandrel 12, screw mandrel 12 is meshed with the side of gear 11 away from rack 94, screw mandrel 12 is extended and arranged along vertical direction, is provided with handle at the upper end of screw mandrel 12, turns handle, makes leading screw drive gear 11 to rotate, The gear 11 further drives the rack 94 and the lifting rod 9 to move until the lower end surface of the positioning plate 10 is flush with the grinding surface of the grinding wheel 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com