Labeling and code-spurting integrated equipment for self-heating food packaging box

A food packaging box and labeling technology, which is applied to lighting and heating equipment, packaging, labeling machines, etc., can solve problems such as non-existent, unfavorable food labeling operations, and loss of heating function of self-heating foods, so as to reduce vibration and avoid Heat generation in advance and the effect of improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

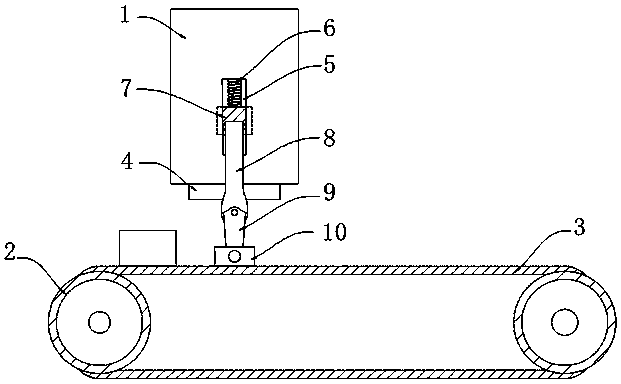

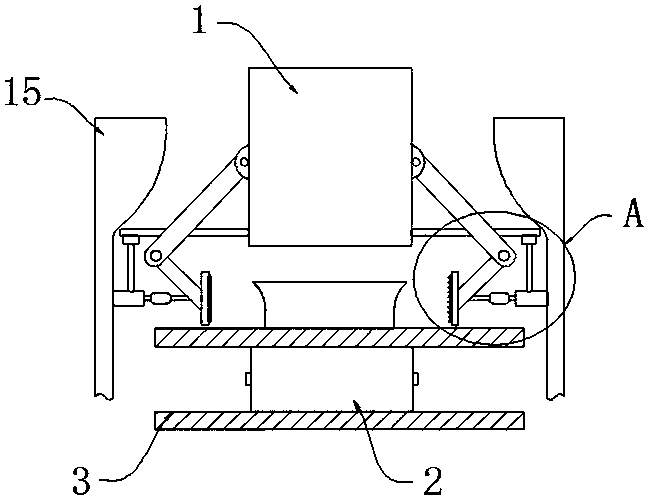

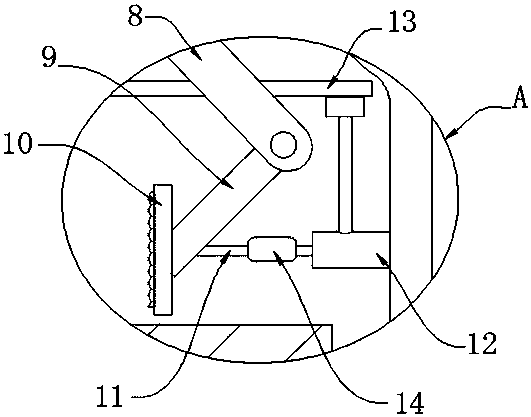

[0016] refer to Figure 1-3 , a self-heating food packaging box labeling and coding integrated equipment, including a labeling machine 1, a belt 3 is provided under the labeling machine 1, two sections of the belt 3 are respectively meshed with a pulley 2, and the rotation of the two pulleys 2 The centers are all fixedly connected with a rotating shaft, and the rotating shaft on a pulley 2 is fixedly connected with an external motor. The bottom of the labeling machine 1 is provided with a sticking dock 4, and the labeling machine 1 is connected with a fixing device. The fixing device includes two chute 5, and the two chute 5 are symmetrically opened on the side wall of the labeling machine 1, and each chute 5 is slidably connected with a slider 7, and the slider 7 is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com