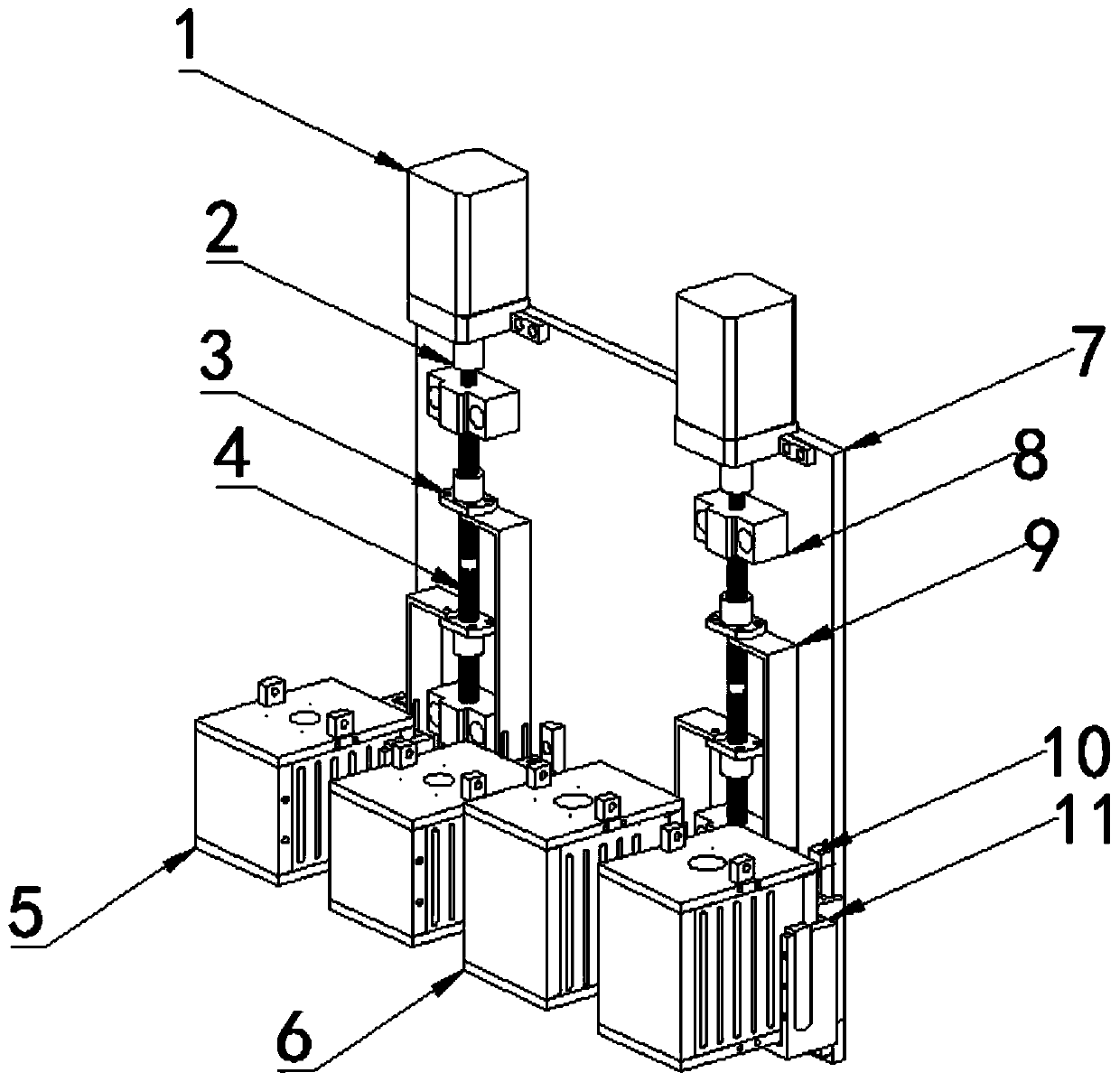

Multi-nozzle interference-free switching device suitable for biological 3D printers and biological 3D printing method

A technology of 3D printers and switching devices, which is applied in the direction of biological material sampling methods, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problem of not being able to well meet the requirements of bionic structures, lack of in-depth research and targeted design , limit the number of bioprinting materials and other issues, achieve high printing effect, improve 3D printing accuracy, and avoid interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Each layer model is only composed of a single printing material

[0046] Step 1: Configure printing materials

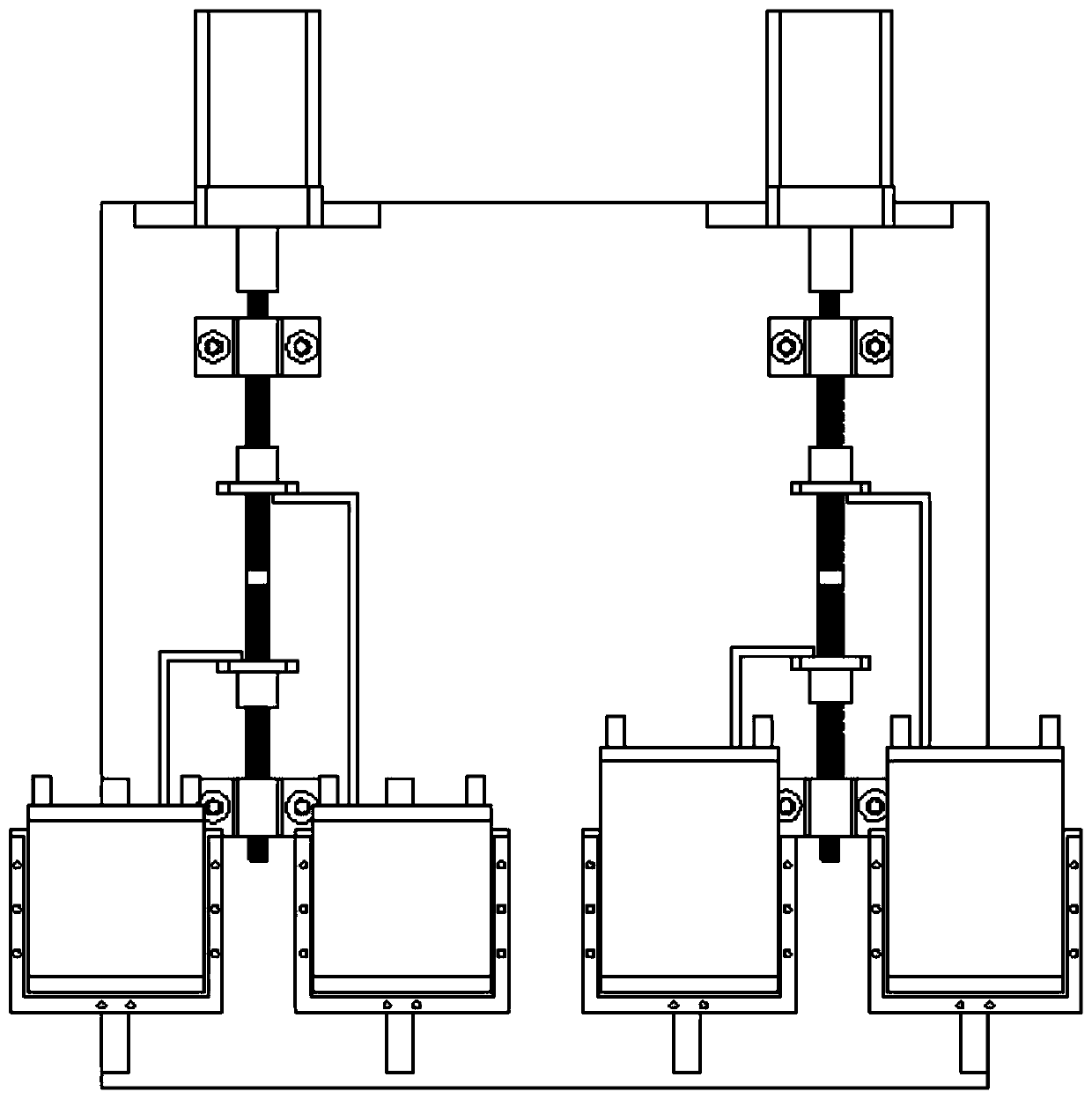

[0047] According to the composition of the model, configure the corresponding printing materials required. In this example, configure 4 copies of the required printing materials, and put them into two 5ml self-made syringes and two 10ml self-made syringes according to the dosage requirements and printing requirements. Syringe barrels, then put two 5ml self-made syringe barrels into two 5ml modular nozzles, and two 10ml self-made syringe barrels into two 10ml modular nozzles, and then put 4 modular nozzles into 4 In a modular nozzle support, both sides are fixed with screws;

[0048] Step 2: Generate print path

[0049] Step A: slice the model in the Z-axis direction according to a certain thickness, each slice of the model is one layer, and then use the control software to generate a path file that can be recognized by the biological 3D printer pr...

example 2

[0053] Example 2: Each layer model is composed of multiple printing materials

[0054] Step 1: Configure printing materials

[0055] According to the composition of the model, configure the corresponding printing materials required. In this example, configure 4 copies of the required printing materials, and put them into two 5ml self-made syringes and two 10ml self-made syringes according to the dosage requirements and printing requirements. Syringe barrels, then put two 5ml self-made syringe barrels into two 5ml modular nozzles, and two 10ml self-made syringe barrels into two 10ml modular nozzles, and then put 4 modular nozzles into 4 In a modular nozzle support, both sides are fixed with screws;

[0056] Step 2: Generate print path

[0057] Step A: slice the model in the Z-axis direction according to a certain thickness, each slice of the model is one layer, and then use the control software to generate a path file that can be recognized by the biological 3D printer printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com