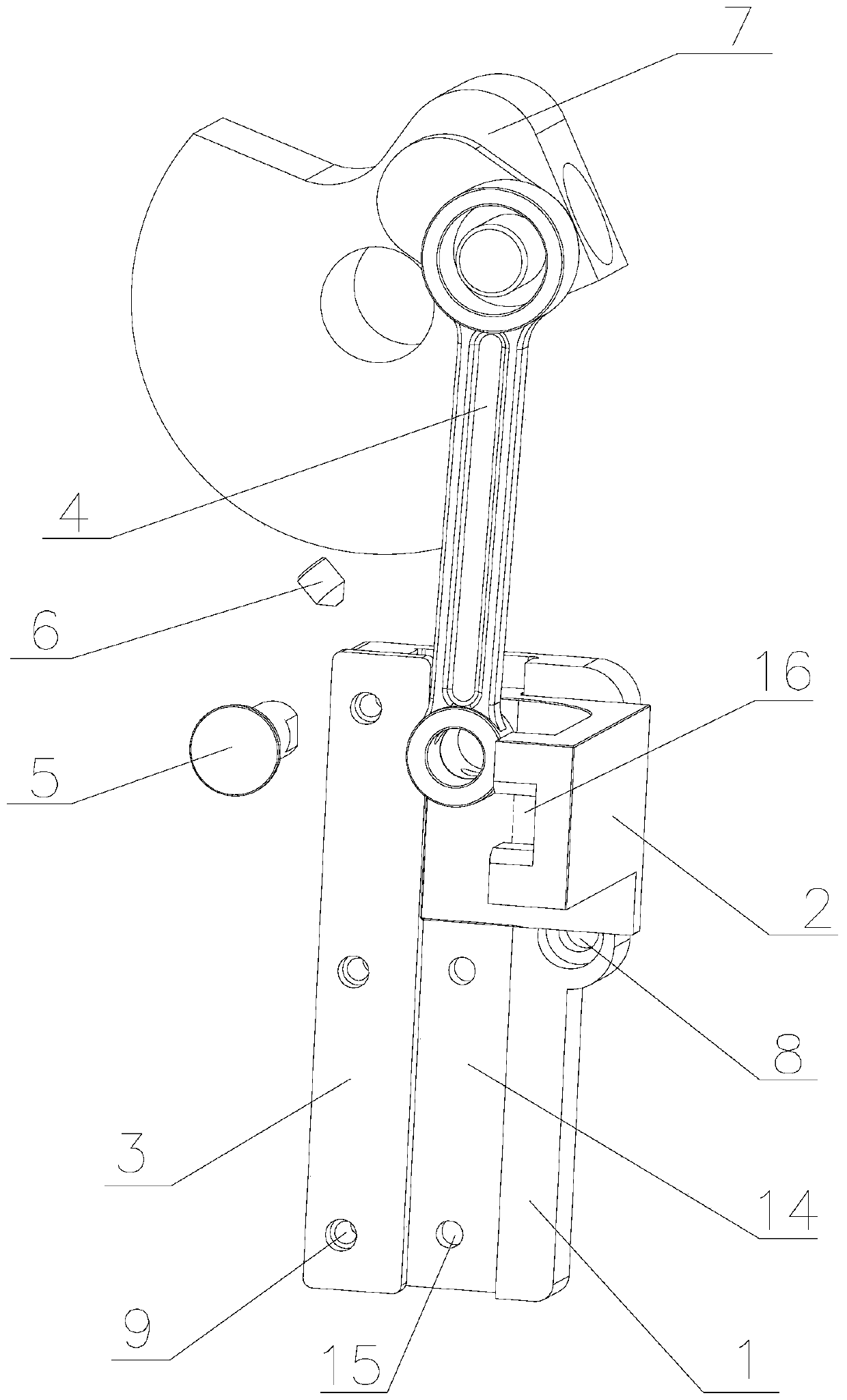

Needle bar linkage sliding device of double-needle longitudinal color-changing computer tricks machine

A sliding device and pattern machine technology, which is applied to sewing machine components, needle holders for sewing machines, textiles and papermaking, etc., can solve the problems of noise, high manufacturing precision and installation and adjustment requirements, and achieve low noise, simplified processing technology, and simplified effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

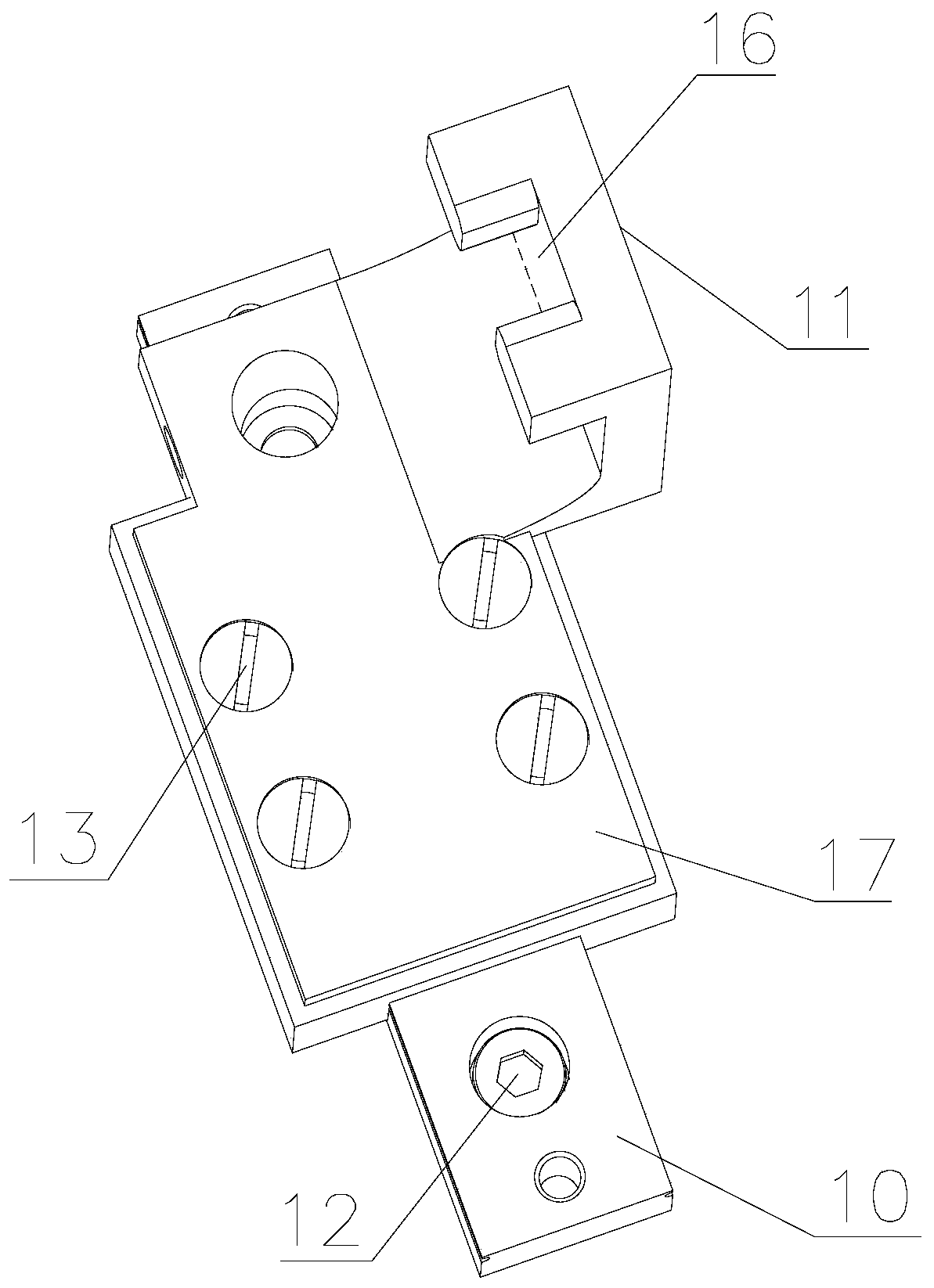

[0017] as attached figure 1 As shown, the present invention provides one of the needle bar linkage sliding devices of a double-needle longitudinal color-changing computerized pattern machine, including a slider base 1, a needle bar linkage slider 2, a driving connecting rod 4, and the middle part of the slider base 1 There is a longitudinal concave chute 14, the root of the needle bar linkage slider 2 is slidably connected to the longitudinal concave chute 14, and slides up and down along the longitudinal concave chute 14, the root of the needle bar linkage slider 2 is along the Y direction There is a shaft hole, and a driving connecting rod 4 is arranged on the outside of the shaft hole. The upper and lower ends of the driving connecting rod 4 are respectively provided with an upper hole and a lower hole. The lower hole of the driving connecting rod 4 and the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap