An automatic anti-wear and torque-reducing tool for coiled tubing

A technology for coiled tubing and tools, applied in the field of automatic anti-wear and torsion-reducing tools, can solve the problems of reducing drilling efficiency, twisting and breaking of coiled tubing, chipping drilling tools, etc., achieving good practicability, reducing back torque, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

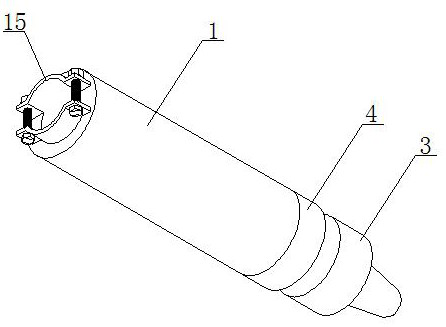

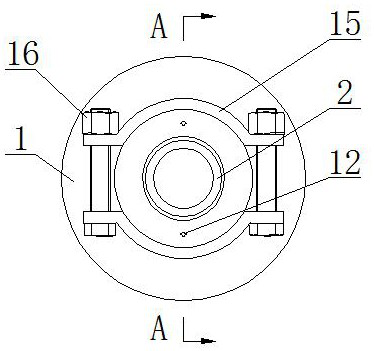

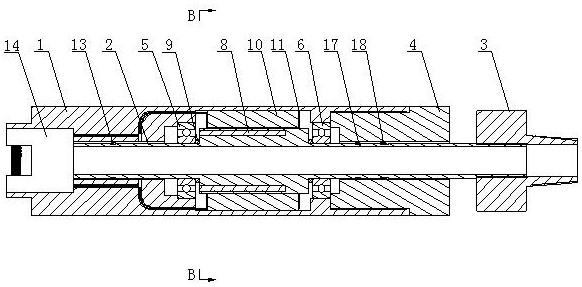

[0025] The automatic anti-wear and torque-reducing tool for coiled tubing operation consists of a housing 1, a mandrel 2, a lower joint 3 and a mounting seat 4. The housing 1 is cylindrical in shape, and one end of the housing 1 is provided with a stepped hole. , the upper bearing 5 is fixedly installed on the stepped hole, the other end of the housing 1 is provided with a limiting shoulder, and the lower bearing 6 is fixedly installed on the limiting shoulder.

[0026] Inside the housing 1, the mandrel 2 is movably installed through the upper bearing 5 and the lower bearing 6, and the upper bearing 5 and the lower bearing 6 center the mandrel 2 in the housing 1; the mandrel 2 is in the shape of a reducing cylinder Sealing ring A9 is set between the mandrel 2 above the upper bearing and the housing 1, and the mandrel 2 forms a sealed state through the annular layer between the sealing ring A9 and the housing 1, so as to prevent the mandrel 2 from being connected to the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com