Oil displacement method suitable for heavy oil reservoir

An oil displacement method and technology for heavy oil reservoirs, which are applied in the field of oil displacement of heavy oil reservoirs, can solve the problems of low recovery factor of high-concentration heavy oil, etc., and achieve improved recovery factor, strong stability, and wide viscosity range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

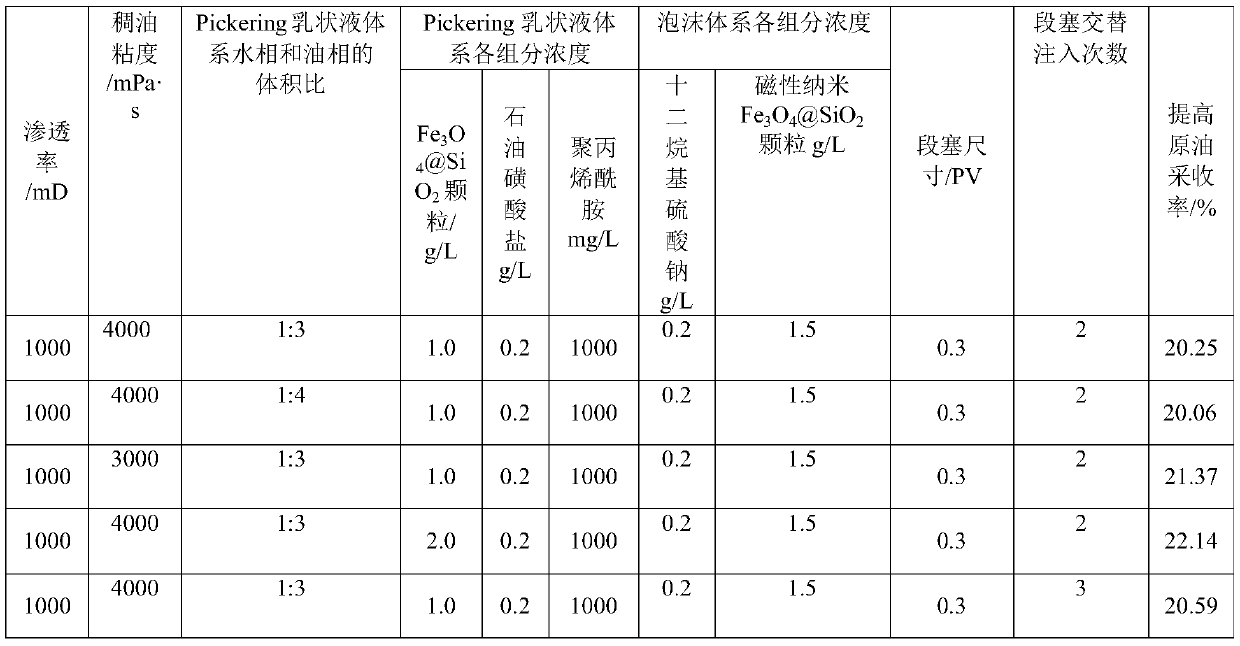

Examples

Embodiment 1

[0025] The preparation method of magnetic nano Fe3O4@SiO2 particles comprises the following steps:

[0026] 1) Fe 3 o 4 Preparation of nanoparticles: dissolving sodium hydroxide in water to form a sodium hydroxide solution with a concentration of 80g / L; adding an equal volume of FeCl 3 solution and FeSO 4 The solution is mixed to obtain a mixed solution of iron salt, FeCl 3 Solution is FeCl 3 Mixed aqueous solution with HCl, FeCl 3 Concentration is 2mol / L, HCl concentration is 0.5mol / L; FeSO 4 Solution is FeSO 4 Mixed aqueous solution with HCl; FeSO 4 The concentration is 1mol / L; the concentration of HCl is 0.5mol / L; the sodium hydroxide solution is heated to 70°C, and the iron salt mixed solution is added dropwise to the sodium hydroxide solution, and the amount of the iron salt mixed solution added is sodium hydroxide 15wt% of the solution, stop heating until the solution turns black, cool to room temperature, separate the black product generated by the reaction, was...

Embodiment 2

[0035] The preparation method of magnetic nano Fe3O4@SiO2 particles comprises the following steps:

[0036] 1) Fe 3 o 4 Preparation of nanoparticles: dissolving sodium hydroxide in water to form a sodium hydroxide solution with a concentration of 80g / L; adding an equal volume of FeCl 3 solution and FeSO 4 The solution is mixed to obtain a mixed solution of iron salt, FeCl 3 Solution is FeCl 3 Mixed aqueous solution with HCl, FeCl 3 Concentration is 2mol / L, HCl concentration is 0.5mol / L; FeSO 4 Solution is FeSO 4 Mixed aqueous solution with HCl; FeSO 4 The concentration is 1mol / L; the concentration of HCl is 0.5mol / L; the sodium hydroxide solution is heated to 75°C, and the iron salt mixed solution is added dropwise to the sodium hydroxide solution, and the amount of the iron salt mixed solution added is sodium hydroxide 15wt% of the solution, stop heating until the solution turns black, cool to room temperature, separate the black product generated by the reaction, was...

Embodiment 3

[0045] The preparation method of magnetic nano Fe3O4@SiO2 particles comprises the following steps:

[0046] 1) Fe 3 o 4 Preparation of nanoparticles: dissolving sodium hydroxide in water to form a sodium hydroxide solution with a concentration of 80g / L; adding an equal volume of FeCl 3 solution and FeSO 4 The solution is mixed to obtain a mixed solution of iron salt, FeCl 3 Solution is FeCl 3 Mixed aqueous solution with HCl, FeCl 3 Concentration is 2mol / L, HCl concentration is 0.5mol / L; FeSO 4 Solution is FeSO 4 Mixed aqueous solution with HCl; FeSO 4The concentration is 1mol / L; the concentration of HCl is 0.5mol / L; the sodium hydroxide solution is heated to 65°C, and the iron salt mixed solution is added dropwise to the sodium hydroxide solution, and the amount of the iron salt mixed solution added is sodium hydroxide 15wt% of the solution, stop heating until the solution turns black, cool to room temperature, separate the black product generated by the reaction, wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap