Thrust chamber of variable working condition liquid-propellant rocket engine

A liquid rocket and engine technology, which is applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of high supply pressure in the supply system and the inability to meet the task requirements of a wide range of variable working conditions, and achieve uniform injection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

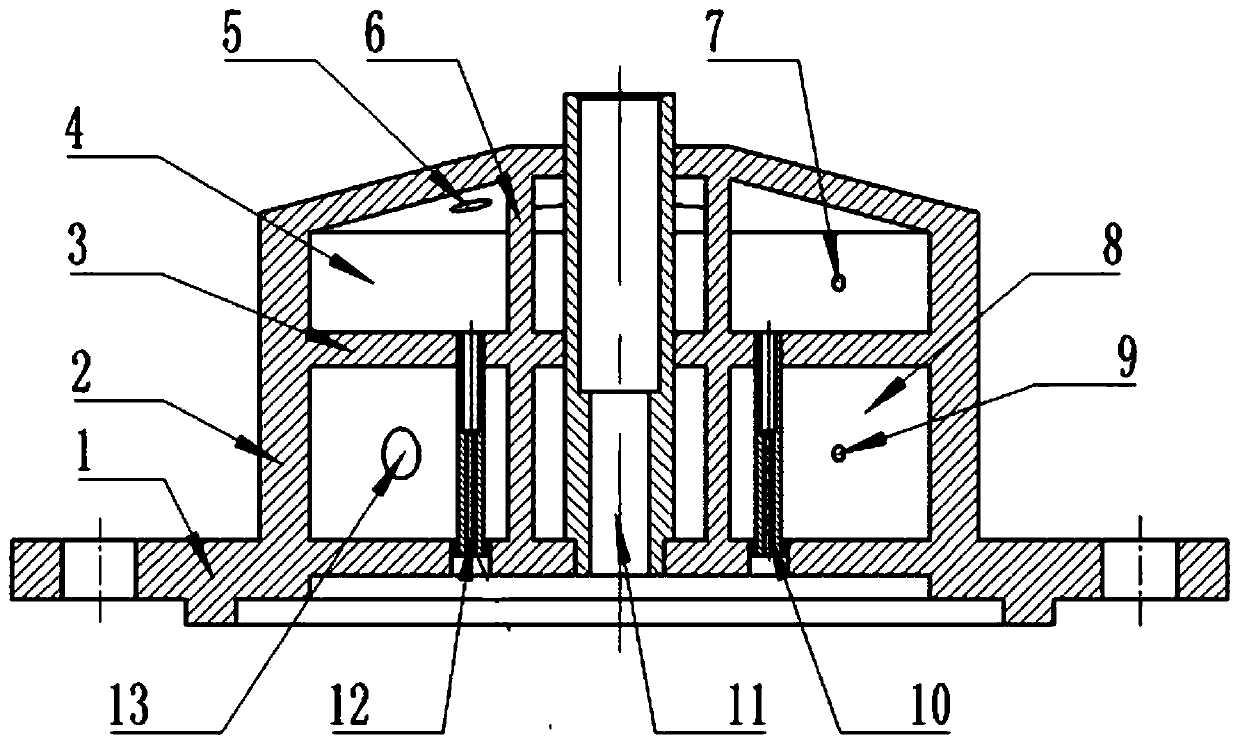

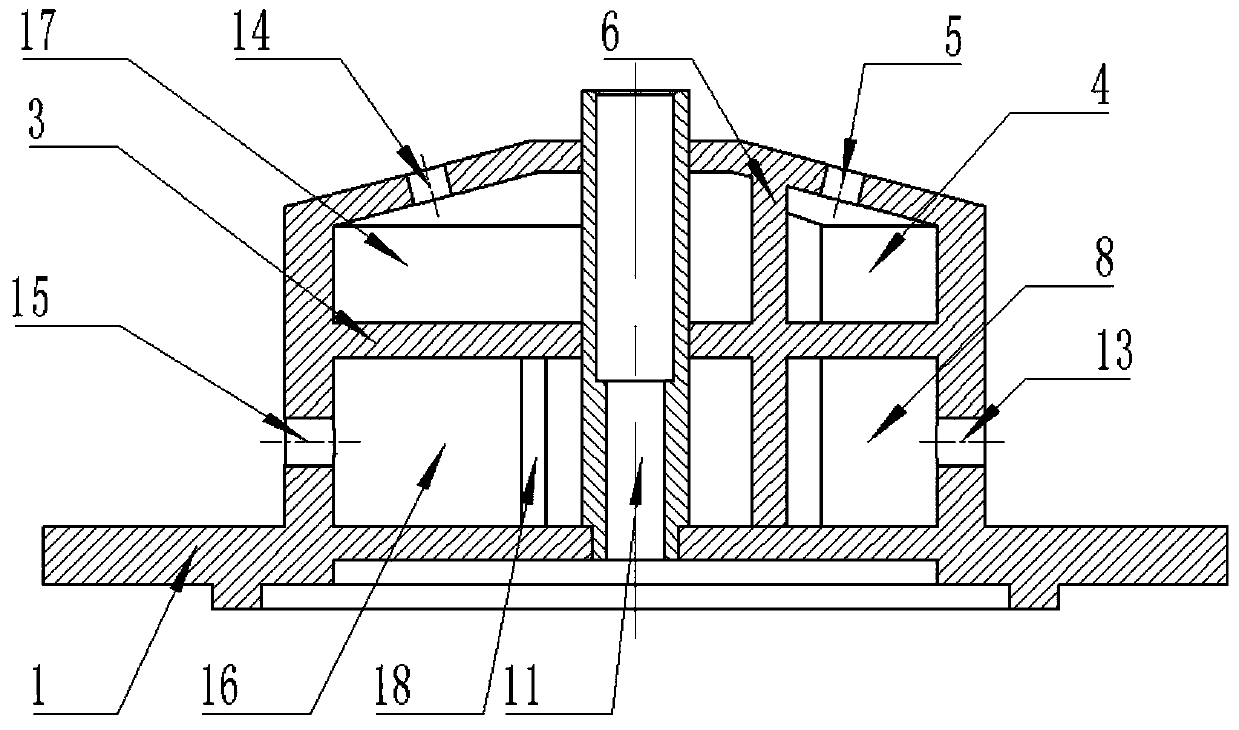

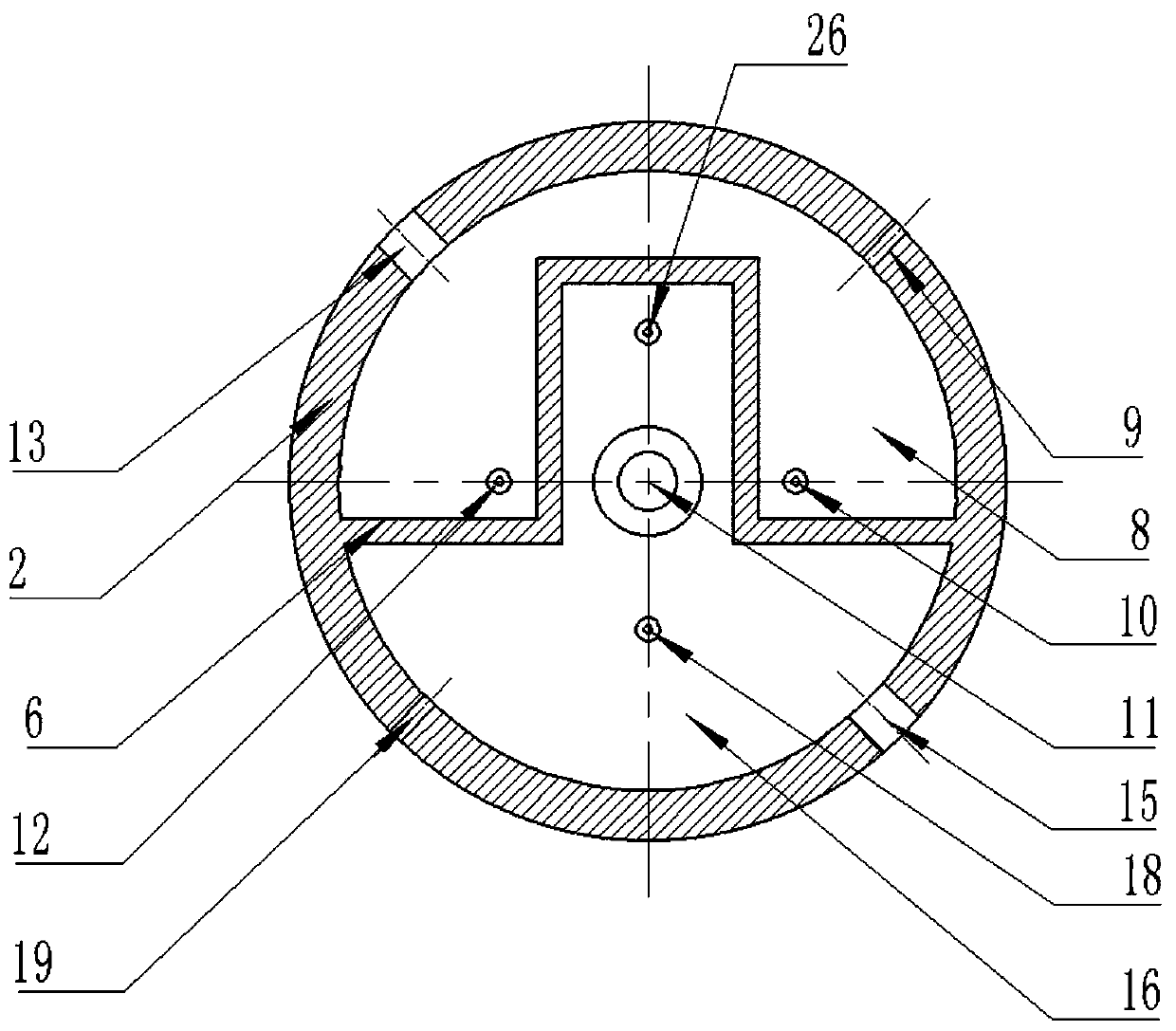

[0023] The present invention is a liquid rocket engine thrust chamber with variable working conditions, such as figure 1 and 2 As shown, it includes: the head body 2, which is a rotary shell structure, the cross section of the rotary shell is circular, and an annular cavity is formed in the shell; the center of the head body 2 is used for axially setting the igniter; the circle An igniter mounting seat 11 is installed in the center of the ring, and the igniter mounting seat 11 is a support. Two groups of gas-liquid outlet holes are opened at the bottom of the rotary housing, and each group is two. The rotary housing includes: a conical housing, with a through hole axially opened at the central axis, and annular cavities with different diameters are formed in the housing; a cylindrical housing, integrally connected with the lower end of the conical housing, and a A through hole is opened in the axial direction, and an annular cavity is formed in the casing. The lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com