Hydraulic wind power generation device

A wind power generation and hydraulic technology, which is applied in wind power generation, wind turbines, wind turbine control, etc., can solve problems such as energy waste and inconvenient installation, reduce power consumption, expand the range of wind speed cut-in and cut-in, and improve wind power utilization efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

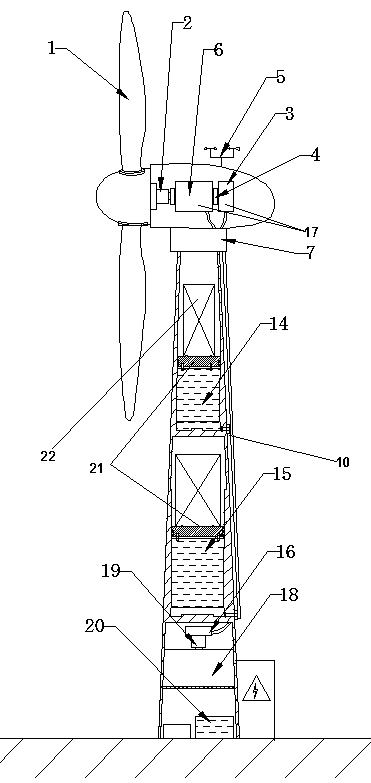

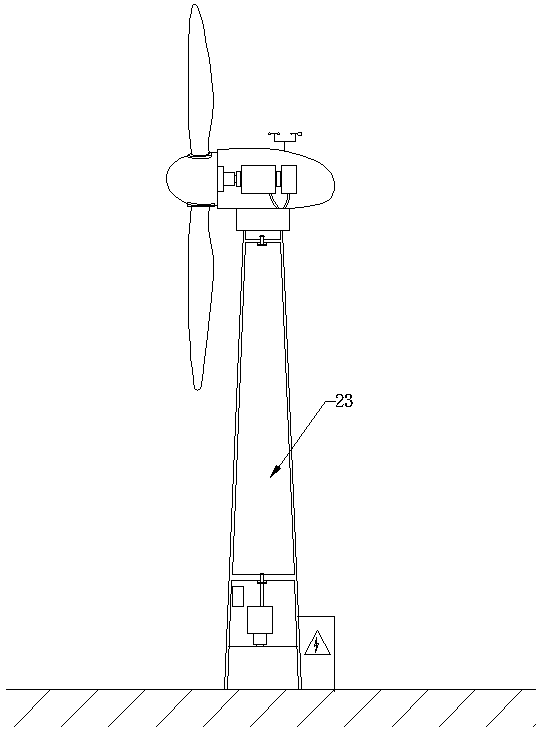

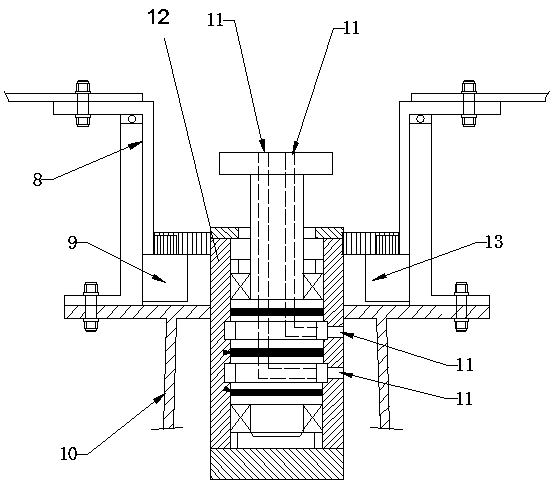

[0035] like figure 1 As shown, a hydraulic wind power generation device is provided with a control module and an accumulator for energy storage with high-pressure working fluid; the fan blade 1 of the wind power generation device drives two or more energy storage pumps through a gearbox 2 17. When the working medium is oil, the energy storage pump is a hydraulic pump. When the hydraulic pump is driven, the oil in the oil tank 20 is pumped into the accumulator 14 to form high-pressure oil for energy storage; the hydraulic pump is divided into large Displacement hydraulic pump 6 and small displacement hydraulic pump 3; each hydraulic pump is connected with a clutch 4 that can disconnect the hydraulic pump from the fan blade; the control module controls the fan blade driven by the clutch according to the current wind speed. The number of hydraulic pumps and the displacement of the hydraulic pumps, thereby expanding the wind speed cut-in and cut-out range of the fan of the wind en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com