Tobacco rod clamping mechanism of semi-automatic cigarette making machine

A clamping mechanism and a tobacco weaving machine technology, applied in the field of tobacco weaving machines, can solve the problems of unadjustable clamping force, inability to clamp tobacco leaves, waste of physical strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

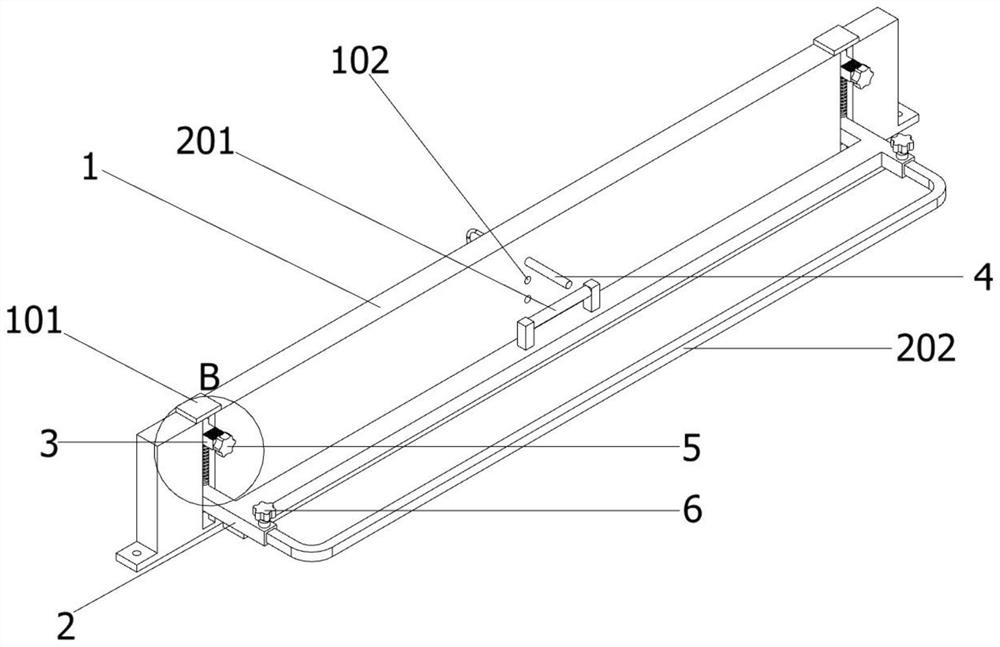

[0034] as attached figure 1 to attach Figure 7 Shown:

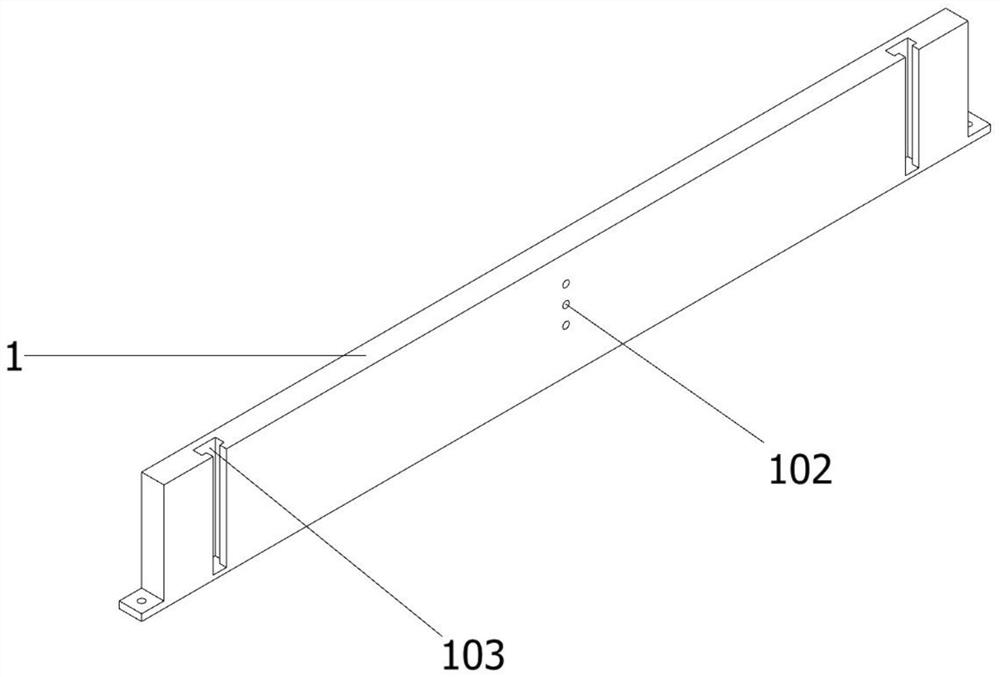

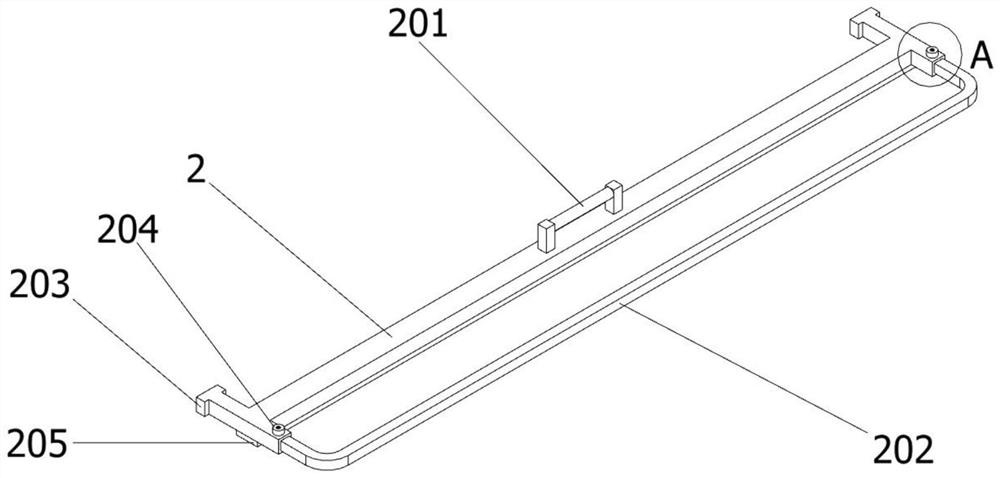

[0035] The present invention provides a tobacco rod clamping mechanism for a semi-automatic cigarette knitting machine, including a rectangular support plate 1, characterized in that: the rectangular support plate 1 is installed on the workbench of the semi-automatic cigarette knitting machine, and the front end of the rectangular support plate 1 is slidably connected with an I-shaped Clamping mechanism 2, as attached figure 1 As shown; two T-shaped limit blocks 3 are slidingly connected to the left and right sides of the rectangular support plate 1, and the front end of each T-shaped limit block 3 is threaded to have a first fastening handwheel 5; I-shaped A second fastening handwheel 6 is threadedly connected to the top of the clamping mechanism 2 on both sides; Figure 6 shown.

[0036] Wherein, the rectangular support plate 1 also includes a rectangular limit block 101, a socket 102, a T-shaped chute 103 and a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com