Pipeline inner wall spraying robot adaptive to pipe diameter

A spraying robot and self-adaptive technology, applied in spraying devices, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of uneven paint spraying, difficulty in manual spraying, and difficulty in cleaning pipes, and achieve simple structure and high spraying efficiency. , the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

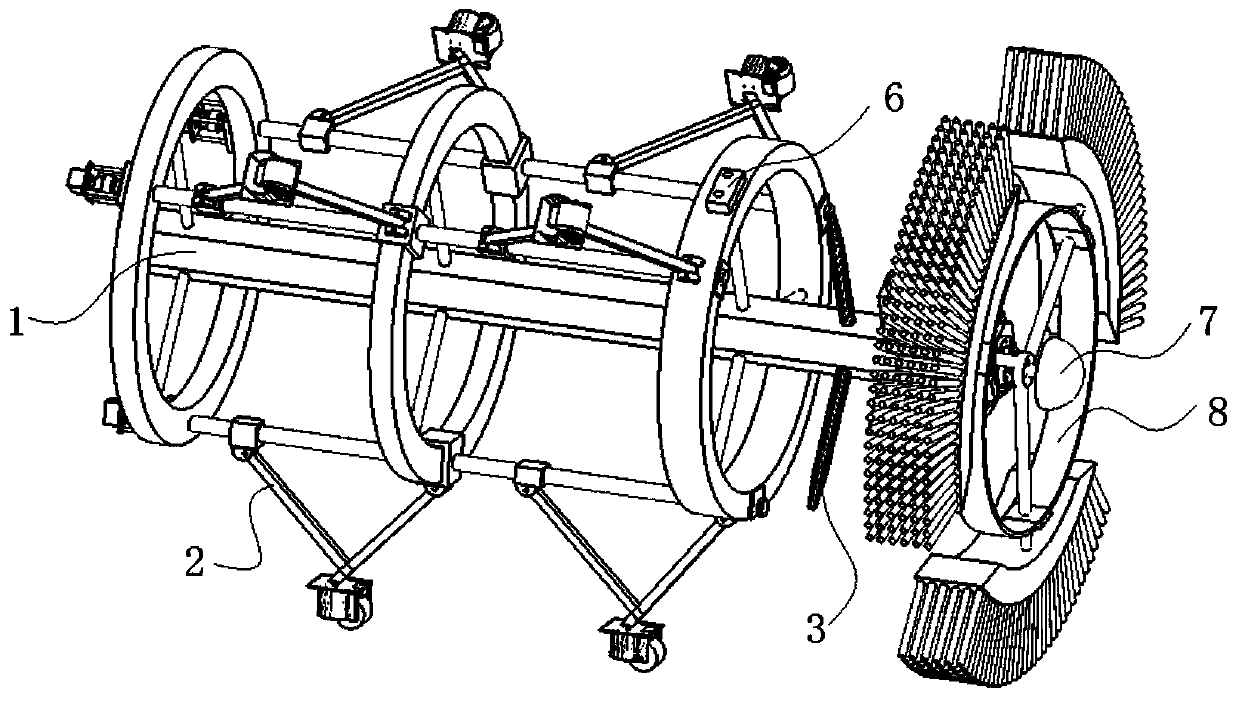

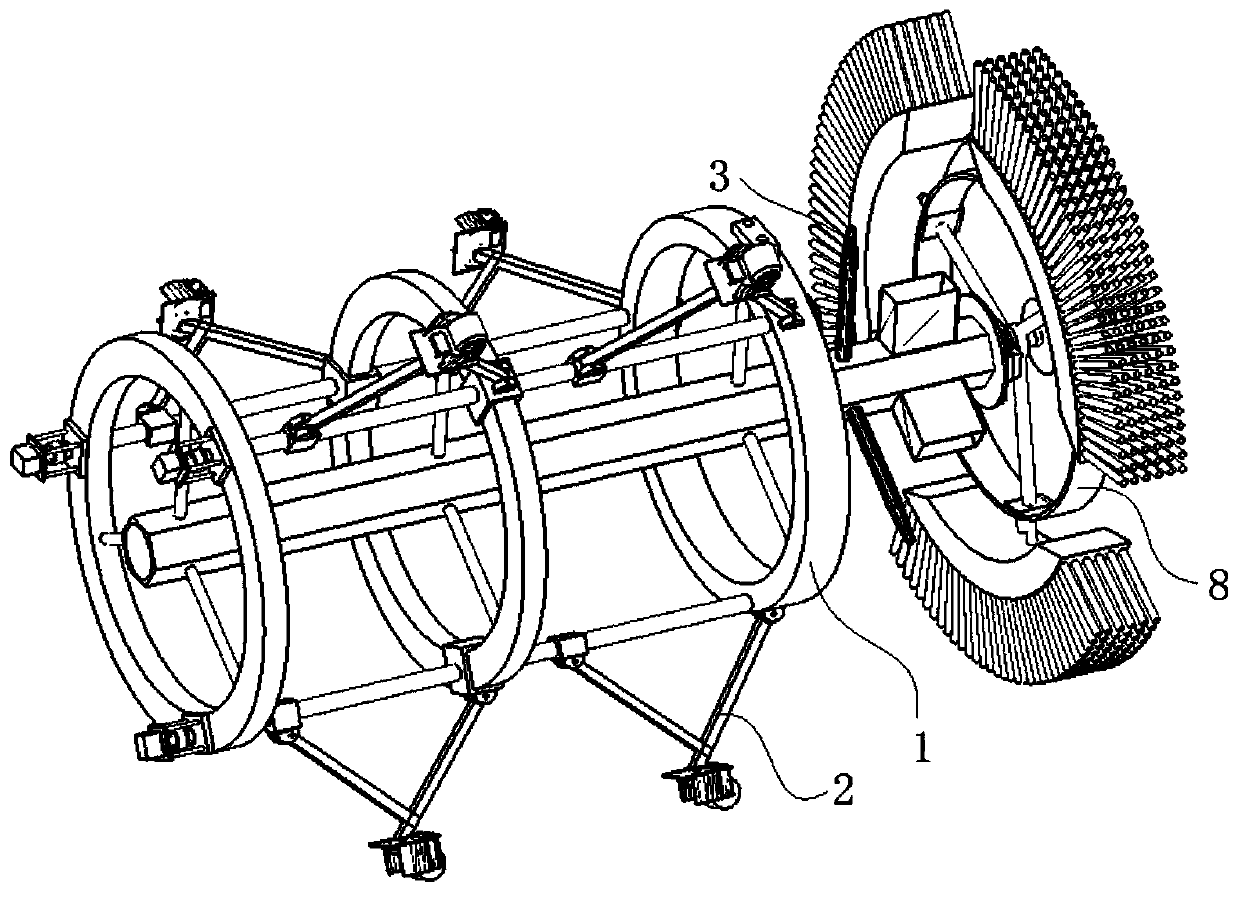

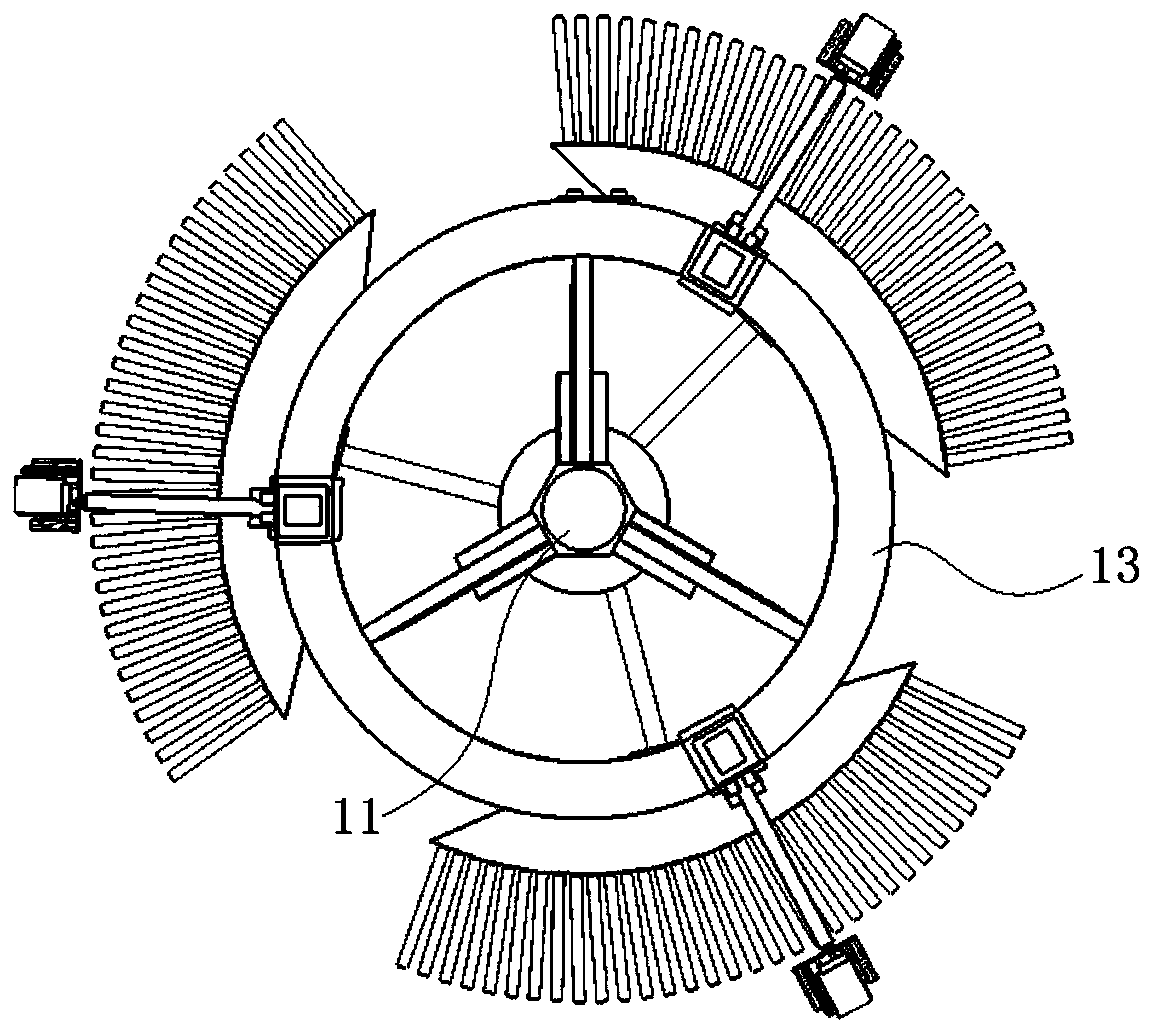

[0033] Such as Figure 1-2 As shown, this embodiment provides a pipeline inner wall spraying robot with adaptive pipe diameter, including a main frame body 1, a motion mechanism 2 and a spraying mechanism 3, the main frame body 1 is used as a fixed base, and the main frame body 1 is a cylinder as a whole Shaped frame structure, specifically, the main frame body 1 includes a main pipe 11, connecting rods 12 and three support rings 13, each support ring 13 is arranged in parallel and aligned at equal intervals, the main pipe 11 runs through the center of each support ring 13, and The connecting rods 12 are connected and fixed with each support ring 13 . Each member of the main frame body 1 is a hollow part to reduce the overall weight of the robot and facilitate walking, such as Figure 4 As shown,.

[0034] Among them, such as Figure 5As shown, the movement mechanism 2 includes a diameter reducing device 4 and a driving wheel assembly 5. The diameter reducing device 4 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com