A hand-held auxiliary grinding and polishing device for the end face of a small-sized cone

A polishing device and cone technology, which is applied in grinding/polishing equipment, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of inconvenient clamping, easy overturning of grinding and polishing, and difficult processing, etc., and achieve improved results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

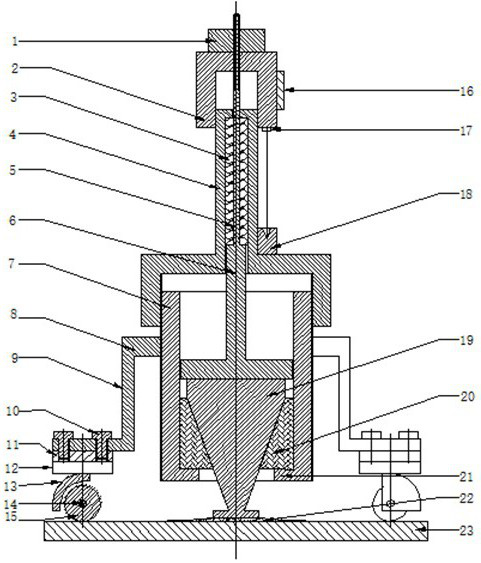

[0018] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention.

[0019] Such as figure 1 and figure 2 The shown hand-held auxiliary grinding and polishing device for the end face of a small-sized cone cylinder includes a fastening nut 1, the fastening nut 1 keeps the position of the length indicating block 2 unchanged, and the fastening nut 1 and the length indicating block 2 It is threadedly connected with the compression block fastening column 5.

[0020] There is a digital display 16 on the side of the length indicating block 2 , and a laser receiver 17 is arranged on the bottom, which is connected with the digital display 16 .

[0021] The lower end of the length indicating block 2 is an upper end cover 4 .

[0022] The upper part of the upper end cover 4 has a built-in compression spring 3 to compress the compression block 6, and a laser emitter 16 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com