Injection mold with step-by-step demolding structure

An injection mold and mold release technology, which is applied in the field of injection molds with a step-by-step mold release structure, can solve the problems of mold complexity, reduced reliability and stability, and inability to release the mold normally, and achieves good reliability and stability. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

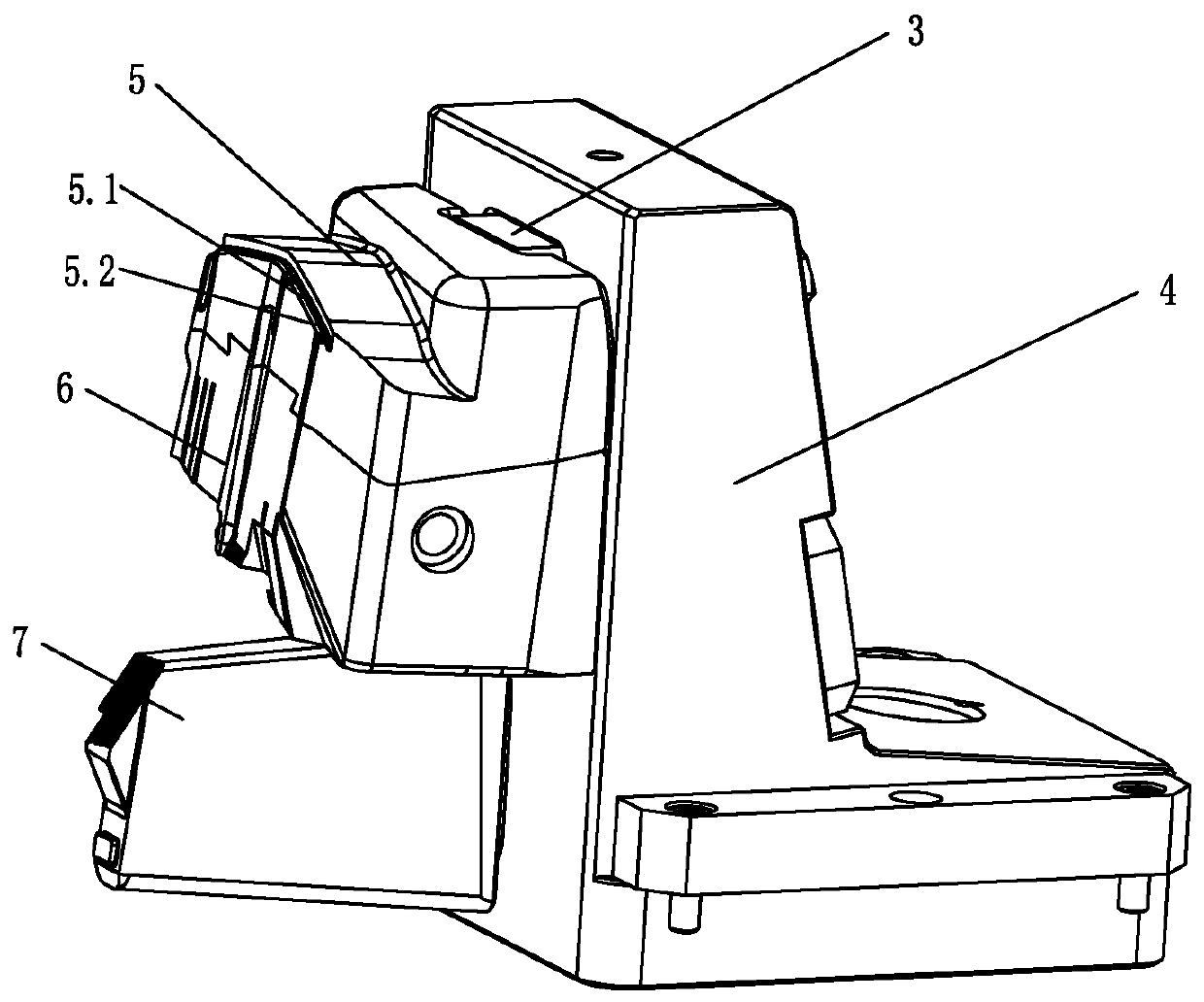

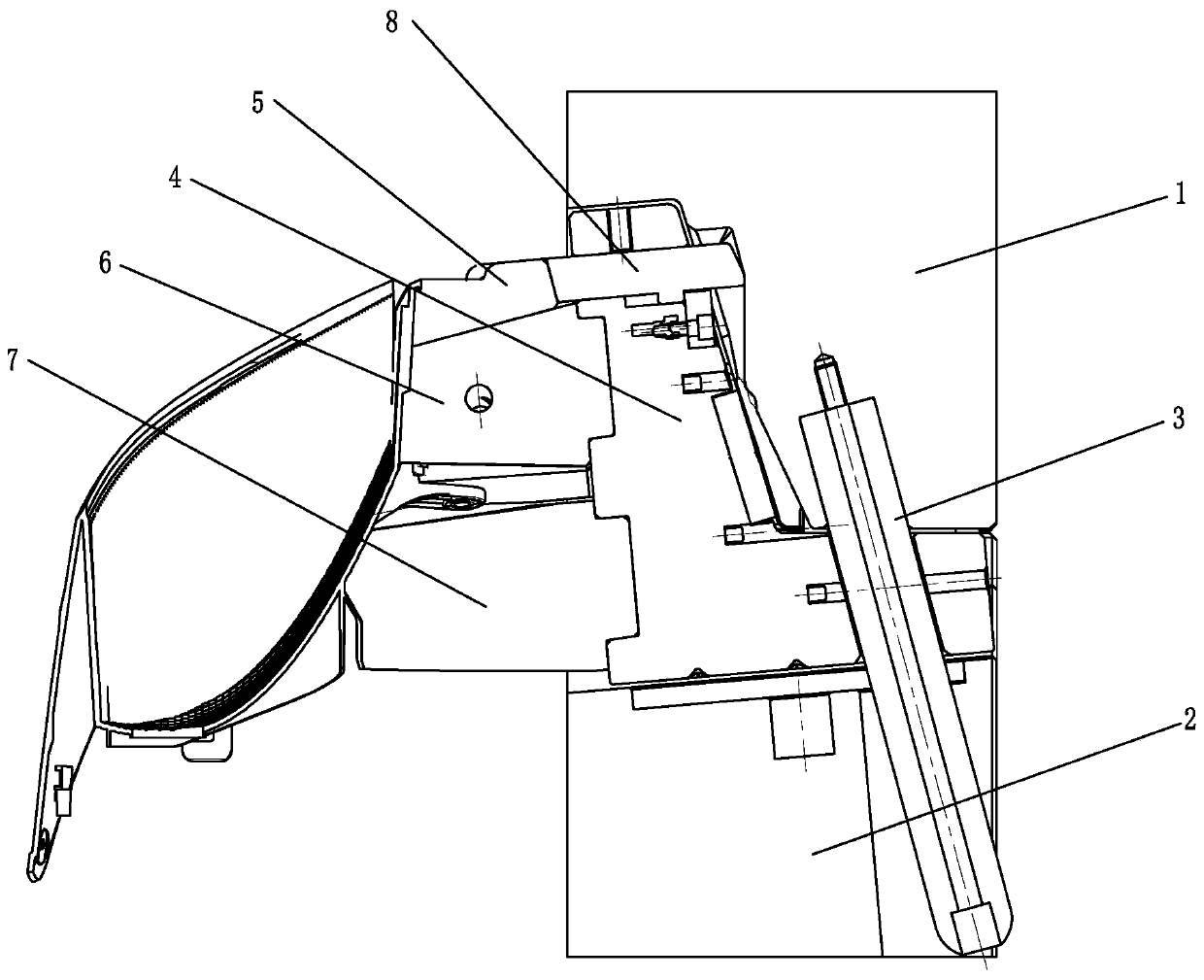

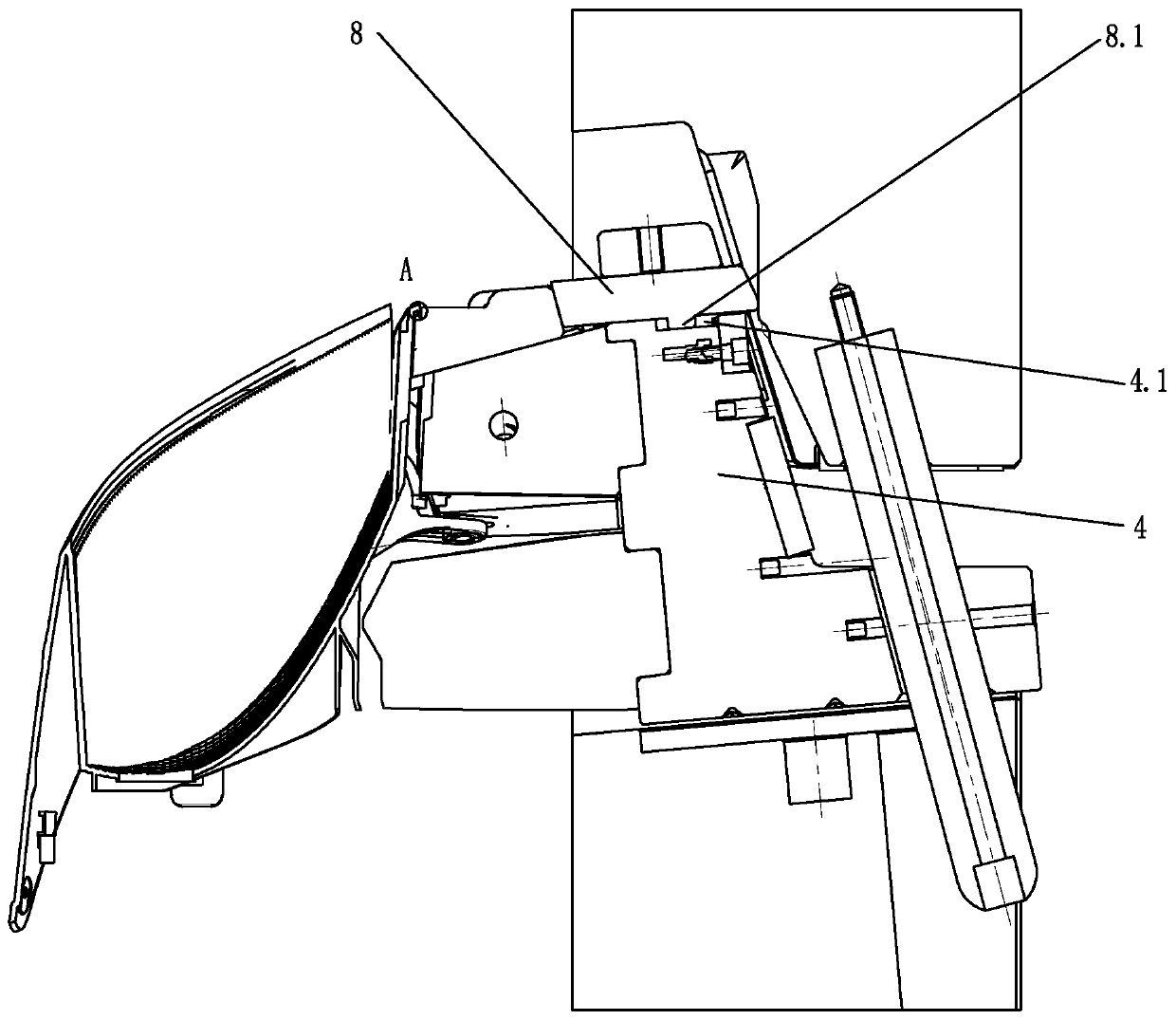

[0025] like Figure 1-5 As shown, the injection mold with the step-by-step demolding structure of the present invention includes an upper mold 1 and a lower mold 2, the upper mold 1 is provided with an inclined guide column 3, and the lower mold 2 is provided with a slider 4, The first insert 5 , the second insert 6 , and the third insert 7 , the sliding block 4 is slidably connected with the lower mold 2 and the connection is the first sliding surface, and the bottom surface of the sliding block 4 is connected to the lower mold 2 . The first sliding surfaces between the top surfaces are inclined at 5-8 degrees, and the side close to the product 101 is lower than the side away from the product 101 .

[0026] The first insert 5 , the second insert 6 , and the third insert 7 are located on the side of the slide 4 from top to bottom and serve as a part of the cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com