Bipyridyl iron complex and its preparation method and application in conjugated diene polymerization

A technology of iron bipyridine and conjugated diene is applied in the direction of iron organic compounds, iron group organic compounds without C-metal bonds, etc., can solve the problems of lack of efficient preparation and the like, and achieves simple and easy preparation, low cost and high activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1. Preparation of bipyridyl iron complex catalyst 1 (structural formula is as follows).

[0043]

[0044] Add anhydrous Fe(acac) to a 50 mL Schlenk bottle under argon atmosphere 2 (127.0mg, 0.5mmol), dissolved in 6mL of absolute ethanol at 60°C; then a solution of 2,2'-bipyridine (78.0mg, 0.5mmol) in ethanol (4mL) was added dropwise to the system. React at 60°C for half an hour, then return to room temperature and stir overnight. The filtrate was collected by filtration, concentrated, washed twice with cold ethanol, and vacuum-dried for 12 h to obtain product 1 as a brown-yellow solid with a yield of 68%.

[0045] Mass Spectrometry: C 20 h 22 FeN 2 o 4 :[M+H]+: theoretical value: 411.1002; measured value: 410.0998.

[0046] Elemental Analysis: C 20 h 22 FeN 2 o 4 : Theoretical value: C, 58.55%; H, 5.41%; N, 6.83%; Measured value: C, 58.34%; H, 5.53%; N, 7.09%.

Embodiment 2

[0047] Example 2. Preparation of pyridine imine iron complex catalyst 2 (structural formula is as follows).

[0048]

[0049] Add anhydrous Fe(acac) to a 50 mL Schlenk bottle under argon atmosphere 3 (211.8mg, 0.6mmol), dissolved in 6mL of absolute ethanol at 60°C; then a solution of 2,2'-bipyridine (93.6mg, 0.6mmol) in ethanol (4mL) was added dropwise to the system. React at 60°C for half an hour, then return to room temperature and stir overnight. The filtrate was collected by filtration, concentrated, washed twice with cold ethanol, and dried in vacuum for 12 h to obtain product 2 as a reddish-brown solid with a yield of 78%.

[0050] Mass Spectrometry: C 25 h 29 FeN 2 o 6 :[M+H]+: theoretical value: 510.1448; measured value: 510.1443.

[0051] Elemental Analysis: C 25 h 29 FeN 2 o 6 : Theoretical value: C, 58.95%; H, 5.74%; N, 5.50%; Measured value: C, 58.54%; H, 5.61%; N, 5.85%.

Embodiment 3

[0052] Example 3. Preparation of pyridine imine iron complex catalyst 3 (structural formula is as follows).

[0053]

[0054] Add anhydrous Fe(acac) to a 50 mL Schlenk bottle under argon atmosphere 2 (127mg, 0.5mmol), dissolved in 6mL of absolute ethanol at 60°C; then, a solution of 5,5'-dimethyl-2,2'-bipyridine (92.0mg, 0.5mmol) in ethanol (4mL) was dropped added to the system. React at 60°C for half an hour, then return to room temperature and stir overnight. The filtrate was collected by filtration, concentrated, washed twice with cold ethanol, and dried in vacuum for 12 h to obtain tan solid product 3 with a yield of 55%.

[0055] Mass Spectrometry: C 22 h 26 FeN 2 o 4 :[M+H]+: theoretical value: 439.1315; measured value: 439.1319.

[0056] Elemental Analysis: C 22 h 26 FeN 2 o 4 : Theoretical value: C, 60.29%; H, 5.98%; N, 6.39%; Measured value: C, 59.90%; H, 6.21%; N, 6.65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

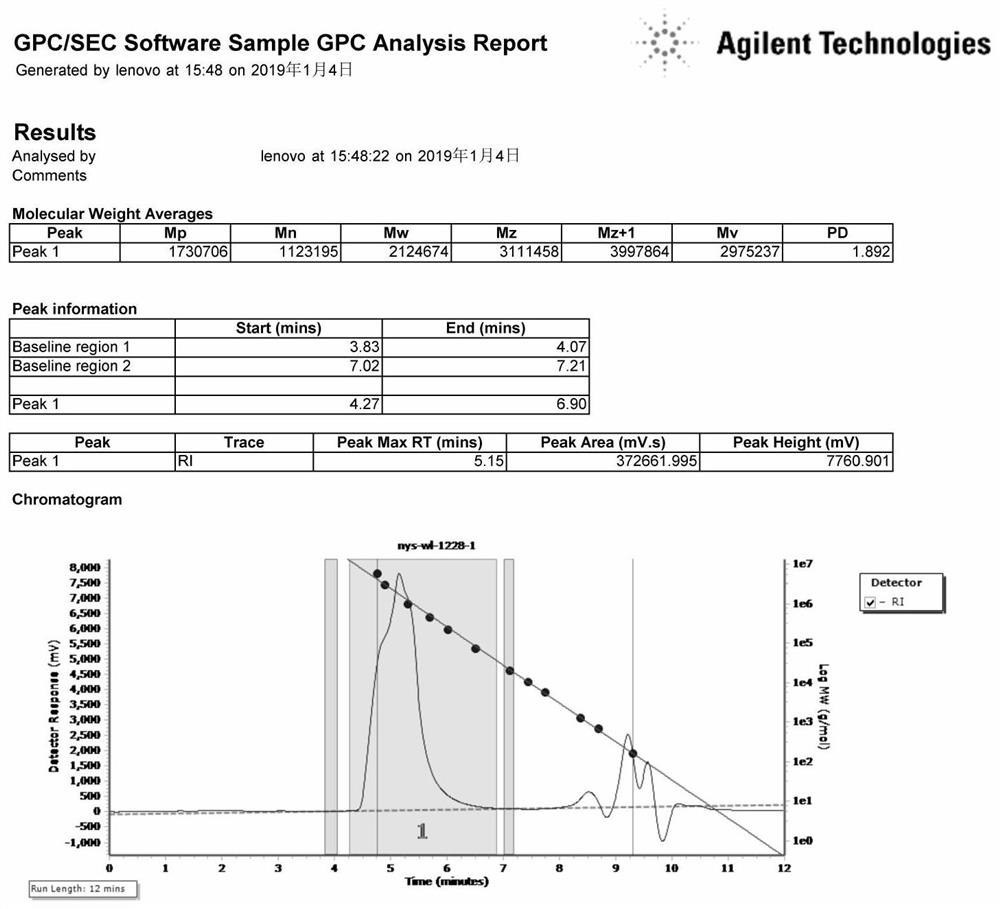

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com