Separation column, separation device and separation method for separating various metal ions from solution

A metal ion and separation method technology, applied in the fields of energy and materials, can solve the problems of many separation steps, unenvironmental processes, etc., and achieve the effects of environmental friendliness and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0065] This preparation example provides a kind of preparation method of the solution to be separated containing multiple metal ions, and this preparation method comprises the following steps:

[0066] The positive electrode material of the waste lithium battery is used as the cathode, and the graphite electrode is used as the anode; wherein, the manufacturing method of the cathode is as follows: the positive electrode material of the waste lithium battery is taken, disassembled, dried, crushed, and pressed in sequence to obtain the cathode, and the electrode thickness of the cathode is 5mm, the compacted density of the cathode is 5g / cm 3 .

[0067] Put the cathode and anode into the ammonium carbonate electrolyte with a concentration of 1moL / L for electrochemical reaction. The potential applied for the electrochemical reaction is 0.2-1.5V, and the potential value is adjusted from large to small, and the time for applying the potential For 2 hours, the solution to be separate...

Embodiment 1

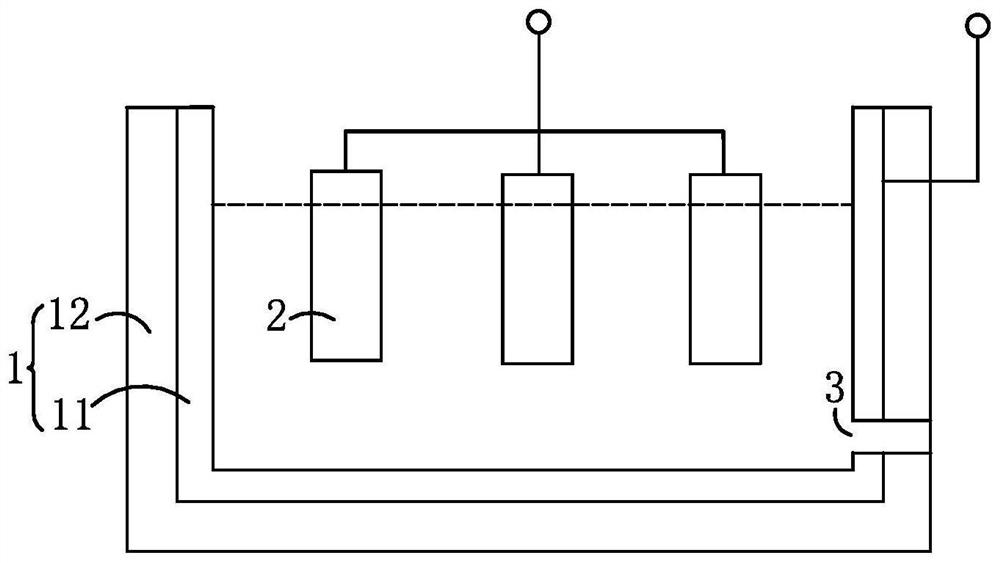

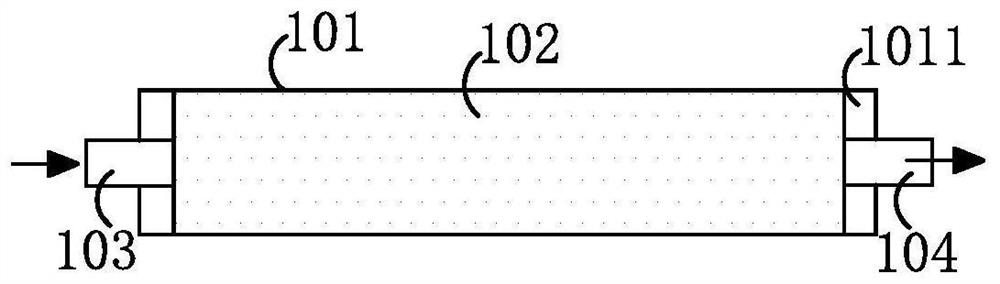

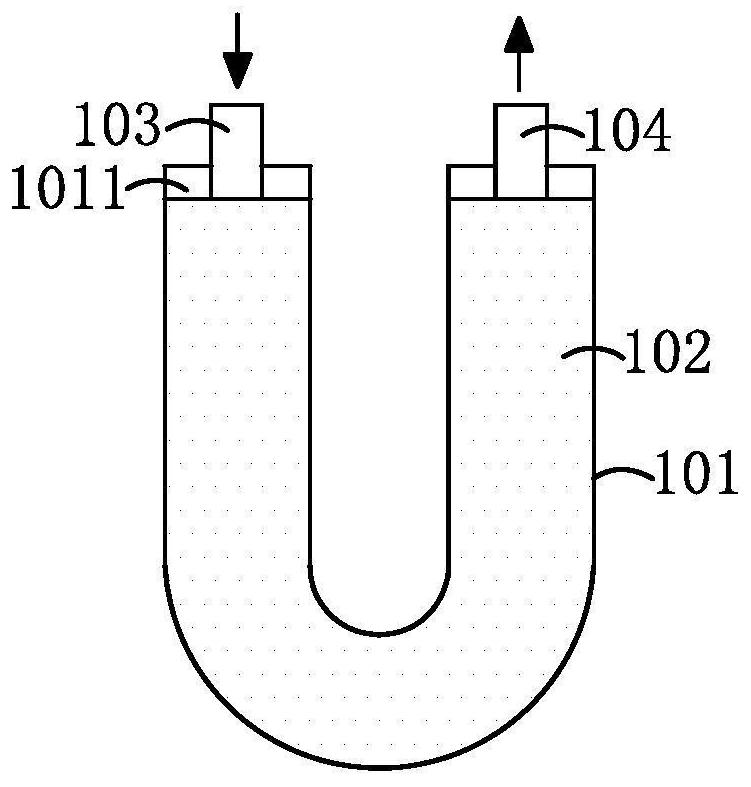

[0074] This embodiment provides a separation column 100 for separating various metal ions from a solution, such as figure 2 As shown, the separation column is strip-shaped, and the separation column includes:

[0075] Separation pipe 101, the two ends of the separation pipe extending along the length direction (i.e. figure 2 The left and right ends of the middle) are respectively provided with potential connection parts 1011;

[0076] Filler 102, the filler 102 is filled in the separation tube 101 by external pressure, and the filling of the filler 102 in the separation tube 101 is uniform and compact, and the filler 102 in this embodiment is diatomite powder with a particle size of about 10 μm;

[0077] The liquid inlet 103 is located at the left end of the separation tube 101, and the liquid inlet 103 is directly connected with the filler 102;

[0078] The liquid outlet 104 is located at the right end of the separation tube 101 , and the liquid outlet 104 is directly con...

Embodiment 2

[0082] This embodiment provides a separation method for separating various metal ions from a solution. The separation method is to use the separation column in the first embodiment above to separate the solution to be separated containing various metal ions prepared in the preparation example.

[0083] combine figure 2 Shown, the separation method of the present embodiment comprises the following steps:

[0084] Driven by the power of the pump (not shown), the solution to be separated containing multiple metal ions is injected from the liquid inlet 103 of the separation column 100, so that the solution to be separated containing multiple metal ions flows from the liquid inlet 103 to the outlet. flow in the direction of port 104;

[0085] The potential connection part 1011 is connected to an external potential, so that different metal ions in the to-be-separated solution containing multiple metal ions flow out from the liquid outlet in different orders.

[0086] In this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com