Weft Insertion Control Method of Air-jet Loom

An air-jet loom and control method technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problem of not being able to fully suppress weft insertion errors, and achieve the effect of suppressing weft insertion errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0018]

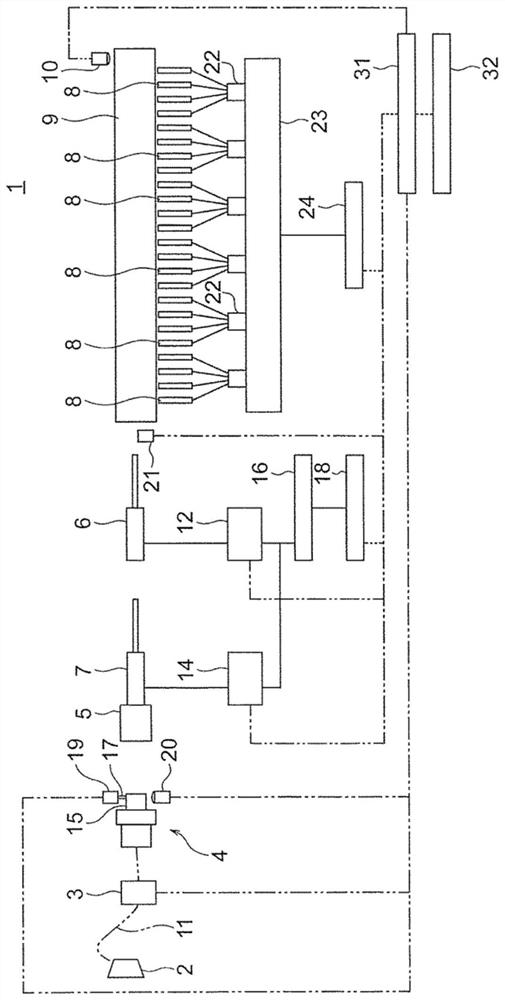

[0019] figure 1 It is a schematic diagram showing a configuration example of the weft insertion device of the air-jet loom according to the embodiment of the present invention.

[0020] The weft insertion device 1 is provided with: a weft yarn bobbin 2, a weft yarn state detection device 3, a weft yarn storage device 4, a weft yarn tension correction device 5, a main nozzle 6, a series nozzle 7, a secondary nozzle 8, a reed 9 for beating up weft, and a weft detecting device. device 10. In addition, the weft insertion device 1 includes a main valve 12 , a tandem valve 14 , a main tank 16 , a regulator 18 , a sub-valve 22 , a sub-tank 23 , a regulator 24 , a control device 31 , and a function panel 32 .

[0021] The weft yarn bobbin 2 functions as a yarn feeding unit that supplies the weft yarn 11 used for weft insertion to the weft yarn accumulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com