Preparation method of comfortable and elastic knitted fabric

A technology of knitted fabrics and stitches, which is applied in the field of preparation of elastic knitted fabrics, can solve the problems of high production cost, non-renewable raw materials, non-conformity to green, environmental protection, energy saving, etc., and achieve excellent elastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

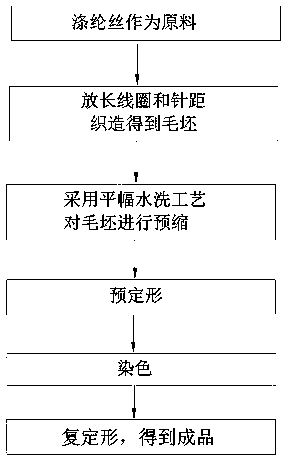

[0024] Such as figure 1 --3 described, a kind of preparation method of elastic knitted fabric, comprises the following steps:

[0025] Step A: select polyester yarn as the raw material yarn count;

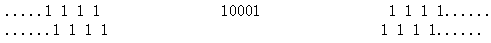

[0026] Step B: Enlarging the needle pitch and lengthening the coil through the manufacturing equipment, and weaving with the predetermined knitting needle arrangement and triangular arrangement to obtain the blank;

[0027] Step C: using an open-width water washing process to perform heat and humidity treatment to preshrink the blank to obtain elasticity;

[0028] Step D: Carry out pre-shaping at a temperature of 150--170 degrees Celsius;

[0029] Step E: dyeing at a temperature of 120-130 degrees Celsius;

[0030] Step F: Perform resetting at a temperature of 130--150 degrees Celsius to obtain a finished product.

[0031] In step A, the polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com