Positioning plate for butt joint of steel columns and steel column welding and installation method

An installation method and positioning board technology, which is applied in the field of positioning boards, can solve the problems of steel columns that cannot be accurately positioned, poor working environment, and slow installation process, and achieve the effects of improving installation speed and construction quality, reducing construction costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

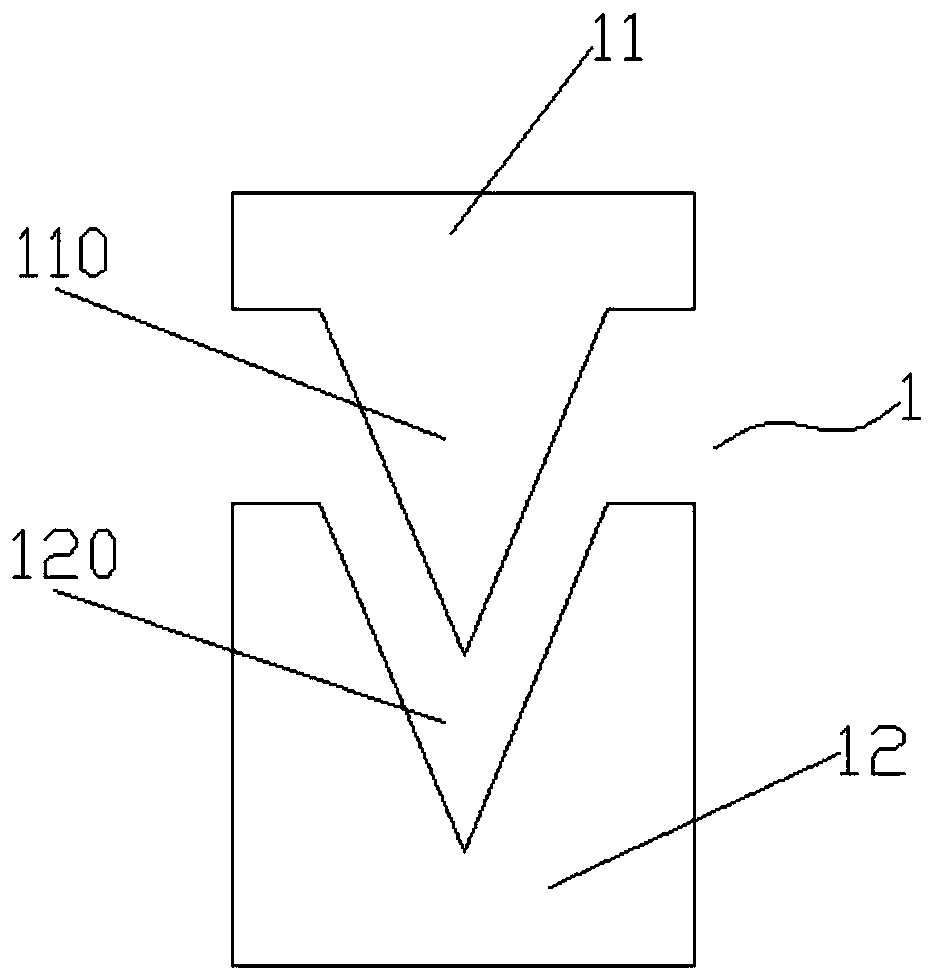

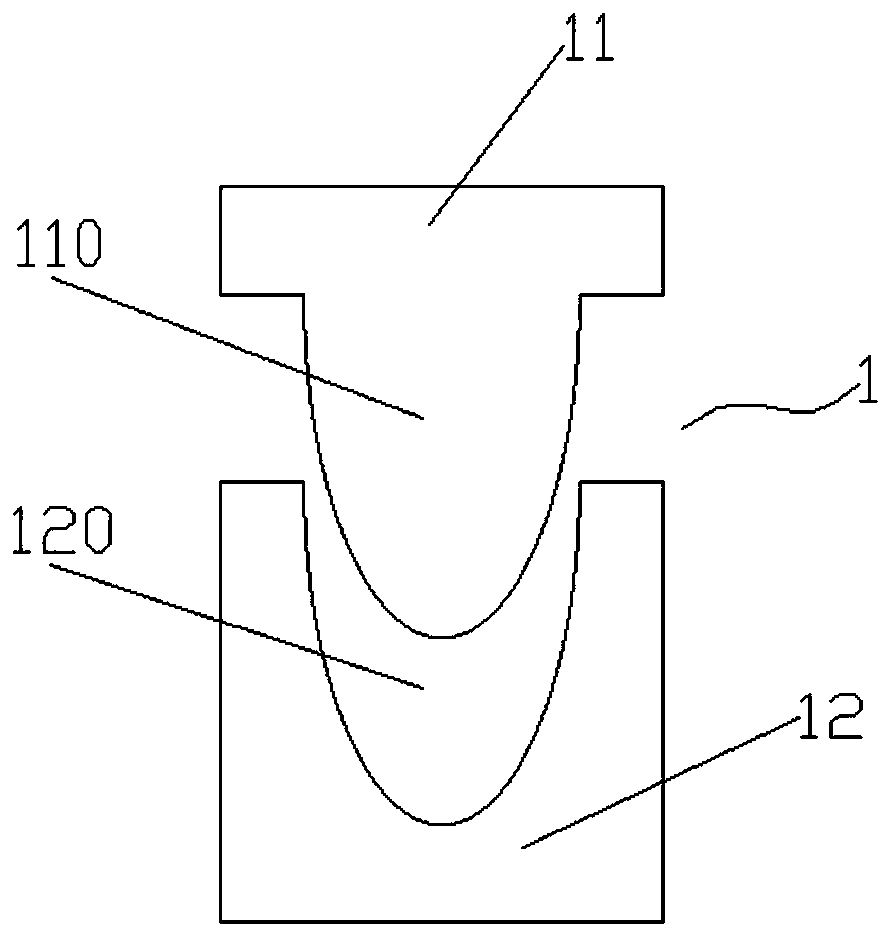

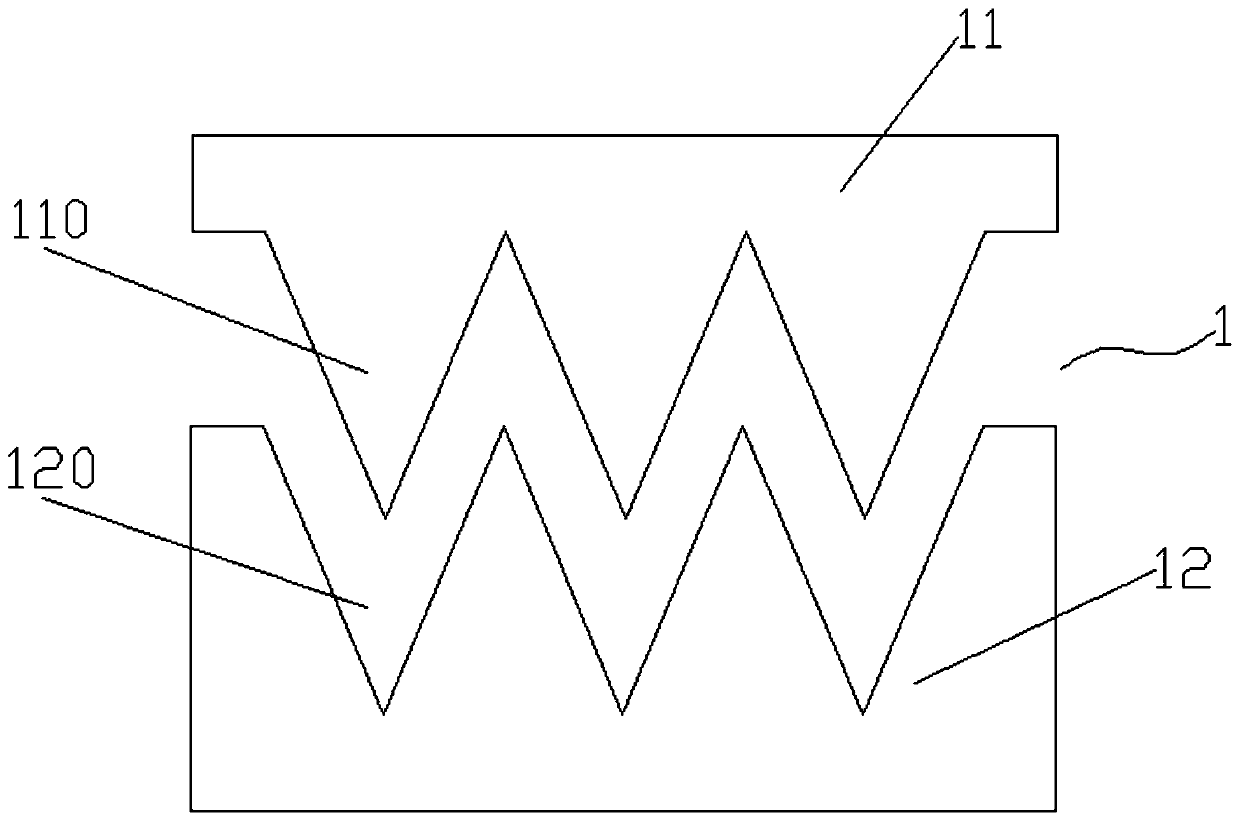

[0028] figure 1 It is a schematic diagram showing the first structure of the positioning plate for steel column butting involved in an embodiment of the present invention. figure 2 It is a schematic diagram showing the second structure of the positioning plate for steel column butting involved in an embodiment of the present invention. image 3 It is a schematic diagram showing the third structure of the positioning plate for steel column butting involved in an embodiment of the present invention. Figure 4 It is a schematic diagram showing the fourth structure of the positioning plate for steel column butting involved in an embodiment of the present invention.

[0029] Such as figure 1 As shown, in this embodiment of the present invention, the positioning plate 1 for steel column butting includes a first connecting plate 11 and a second connecting plate 12. A raised portion 110 is provided on one side of the first connecting plate 11, and a concave portion 120 that matches the ab...

Embodiment 2

[0035] Figure 5 It is a schematic diagram showing the structure of the steel column involved in an embodiment of the present invention during installation.

[0036] reference Figure 5 , To introduce the steel column installation method in this embodiment. The installation method is used to install the upper and lower steel columns. The steel columns can be box-shaped columns, cross-shaped columns, or H-shaped columns. This installation method can be applied to at least two sides of the upper and lower steel columns in the same plane. This embodiment describes the installation method by taking a box-shaped column as an example. The specific installation method includes the following steps:

[0037] Step S1: According to the size of the steel column, the positioning plate 1 described in the first embodiment is produced, wherein the width of the positioning plate 1 should be between one quarter and one half of the width of the side of the steel column. In this embodiment, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com