Volume measurement method and system for minerals loaded by ore bucket

A volume measurement and mine bucket technology, which is applied in the field of volume measurement methods and systems for minerals contained in mine buckets, can solve problems such as high safety risks, low mine extraction efficiency, and increased production costs, and achieve the effect of measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

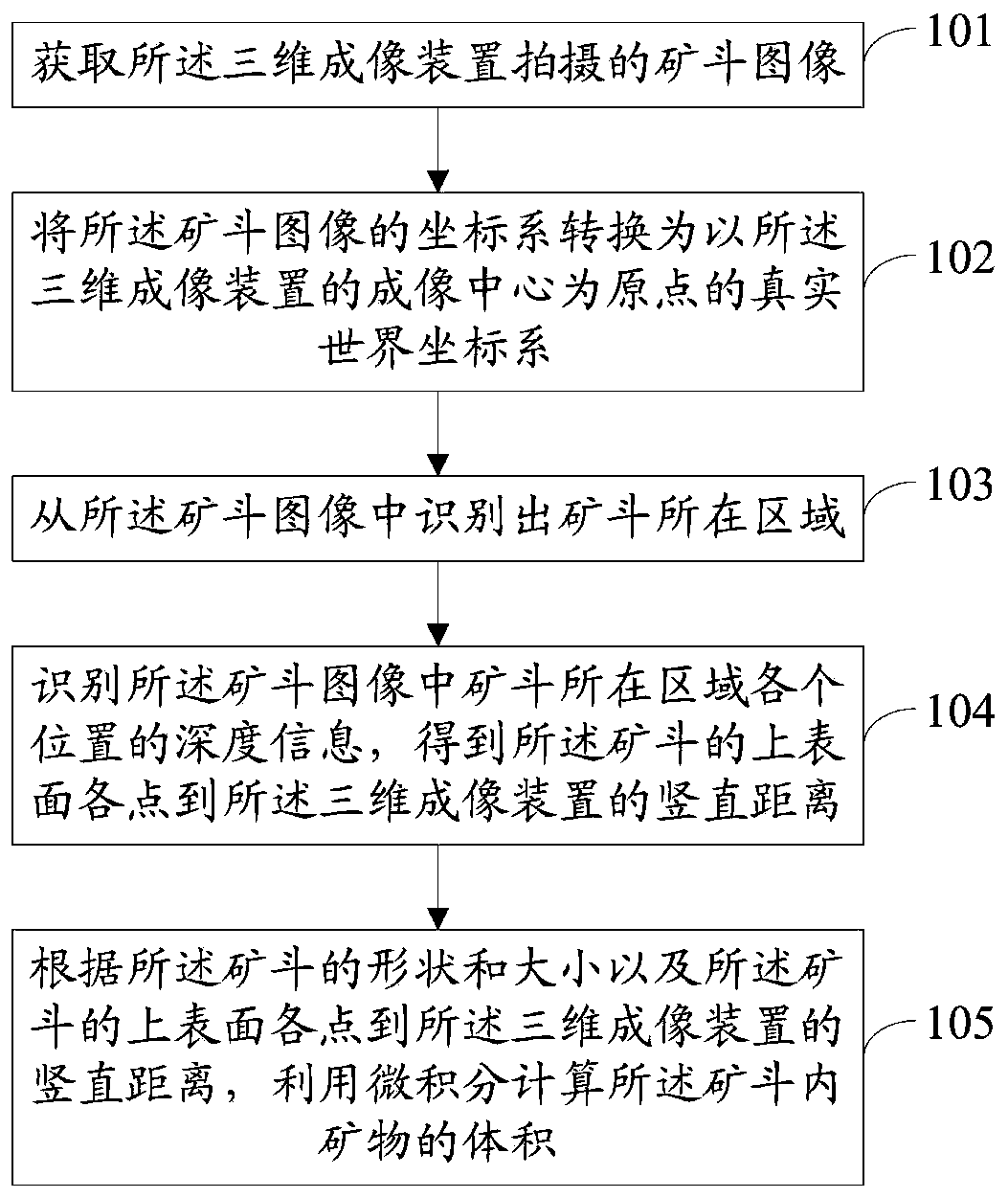

[0059] The method for measuring the volume of minerals contained in a mine hopper in Embodiment 1 is applied to a measuring device.

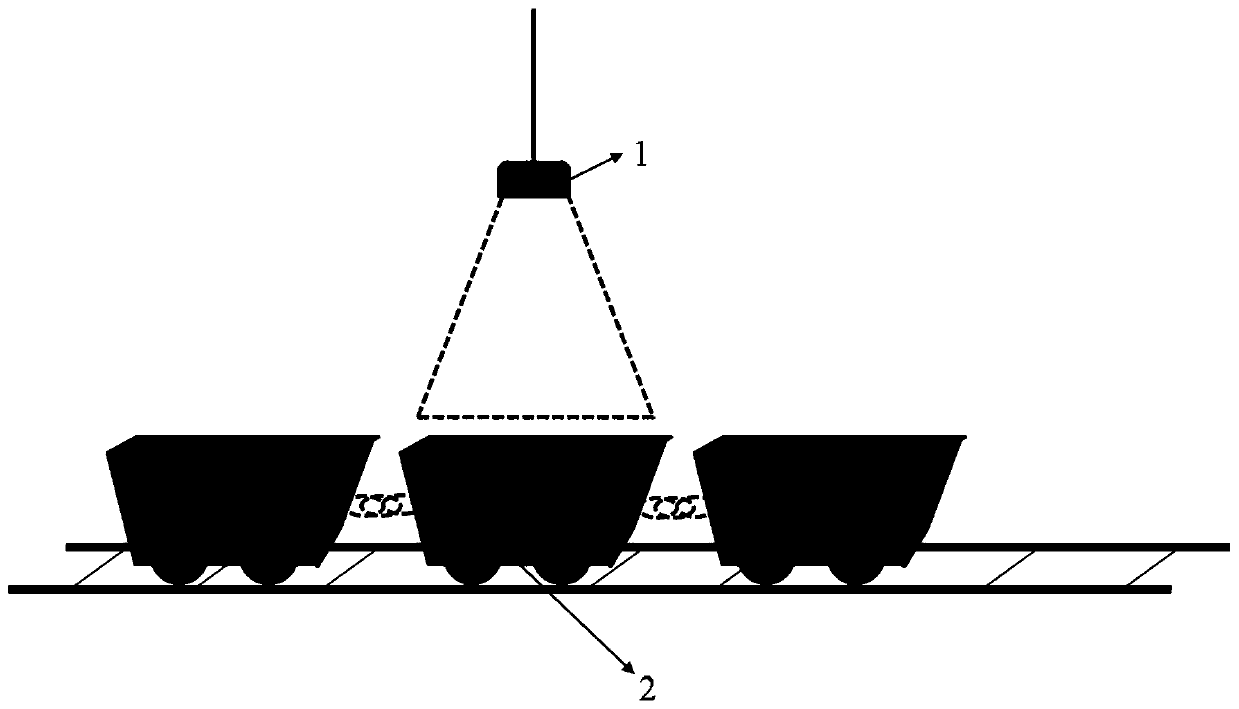

[0060] figure 2 It is a structural diagram of a measuring device used in the method for measuring the volume of minerals carried in a bucket in Example 1 of the present invention.

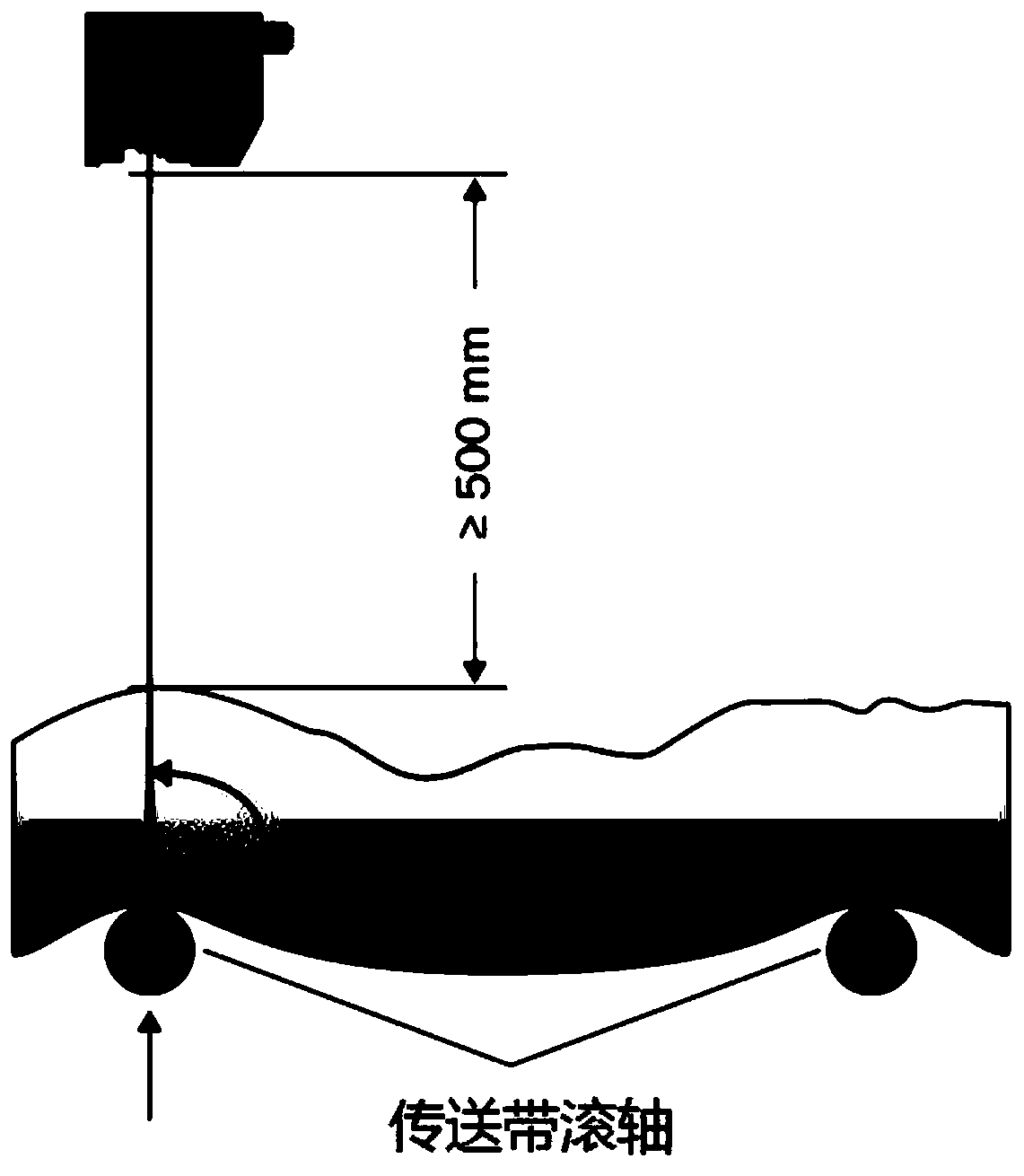

[0061] see figure 2 , the measuring device includes a processor (not shown in the figure) and a three-dimensional imaging device 1 located directly above the track of the mine bucket; the height of the three-dimensional imaging device 1 is higher than that of the mine bucket 2. The shooting direction of the three-dimensional imaging device 1 faces directly below; the output end of the three-dimensional imaging device 1 is connected to the input end of the processor; the three-dimensional imaging device 1 is used to take images of mine buckets, and the processor is used for Calculate mineral volume.

[0062] The three-dimensional imaging device may be a depth cam...

Embodiment 2

[0104] This embodiment 2 discloses a system for measuring the volume of minerals carried in a mine bucket, which is applied to a measuring device; the measuring device includes a processor and a three-dimensional imaging device located directly above the track of the mine bucket; the shooting direction of the three-dimensional imaging device faces Directly below; the output end of the three-dimensional imaging device is connected to the input end of the processor; the three-dimensional imaging device is used to take images of mine buckets, and the processor is used to calculate mineral volume;

[0105] The measurement system includes:

[0106] An image acquisition module, configured to acquire the mine bucket image captured by the three-dimensional imaging device; the mine bucket image captured by the three-dimensional imaging device includes image depth information;

[0107] A depth acquisition module, configured to identify the depth information of each position in the area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com