Feed rolling device with pre-compaction function

A rolling device and pre-compacting technology, applied in the fields of feed, food science, application, etc., can solve the problems of easy pulverization, low adhesion, unfavorable storage and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

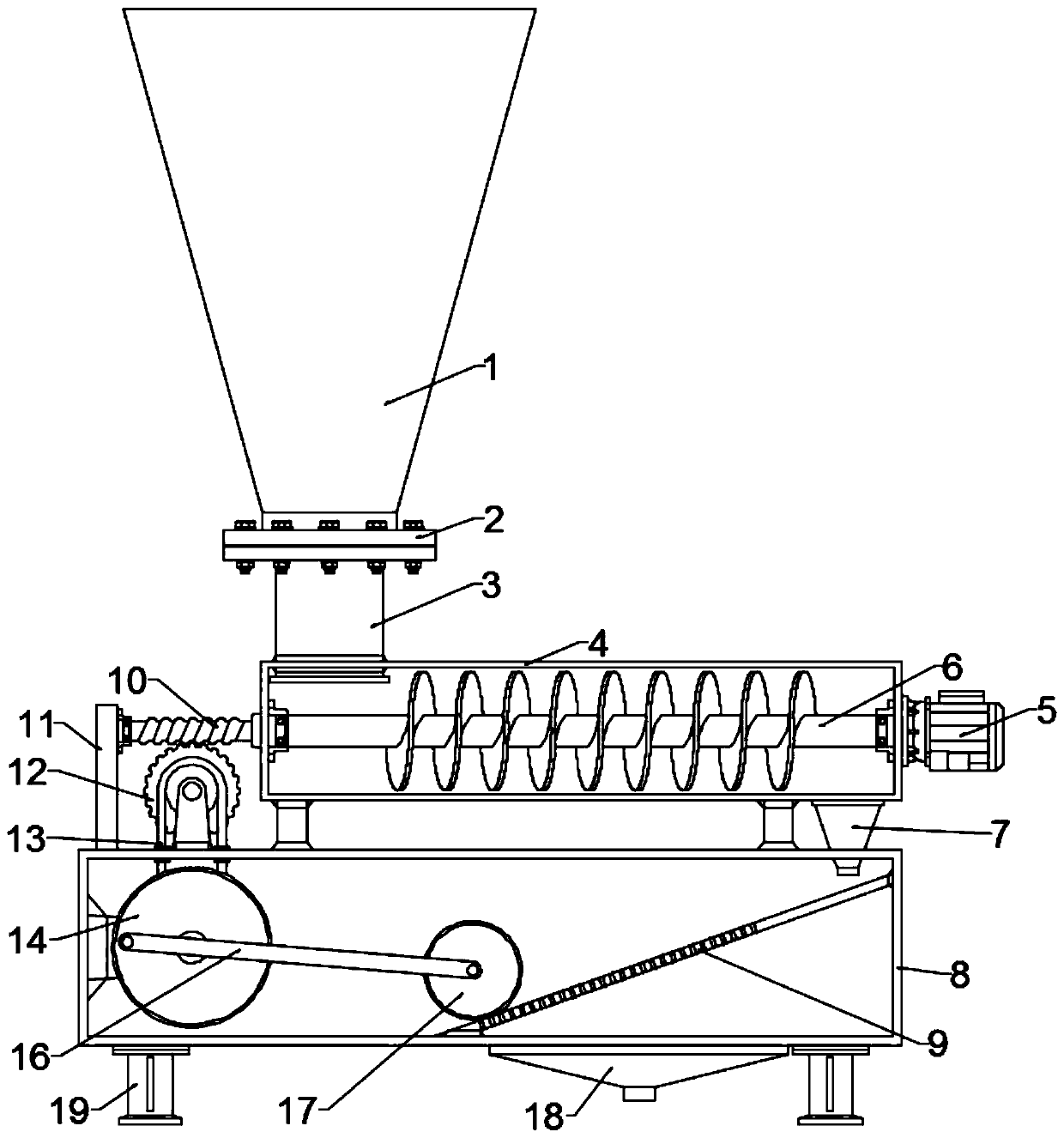

[0021] see Figure 1~3 , in an embodiment of the present invention, a feed rolling device with a pre-compacting function includes a hopper 1 for containing feed raw materials, a pre-extrusion assembly connected to the hopper 1, and a rolling assembly connected to the pre-extrusion assembly. components;

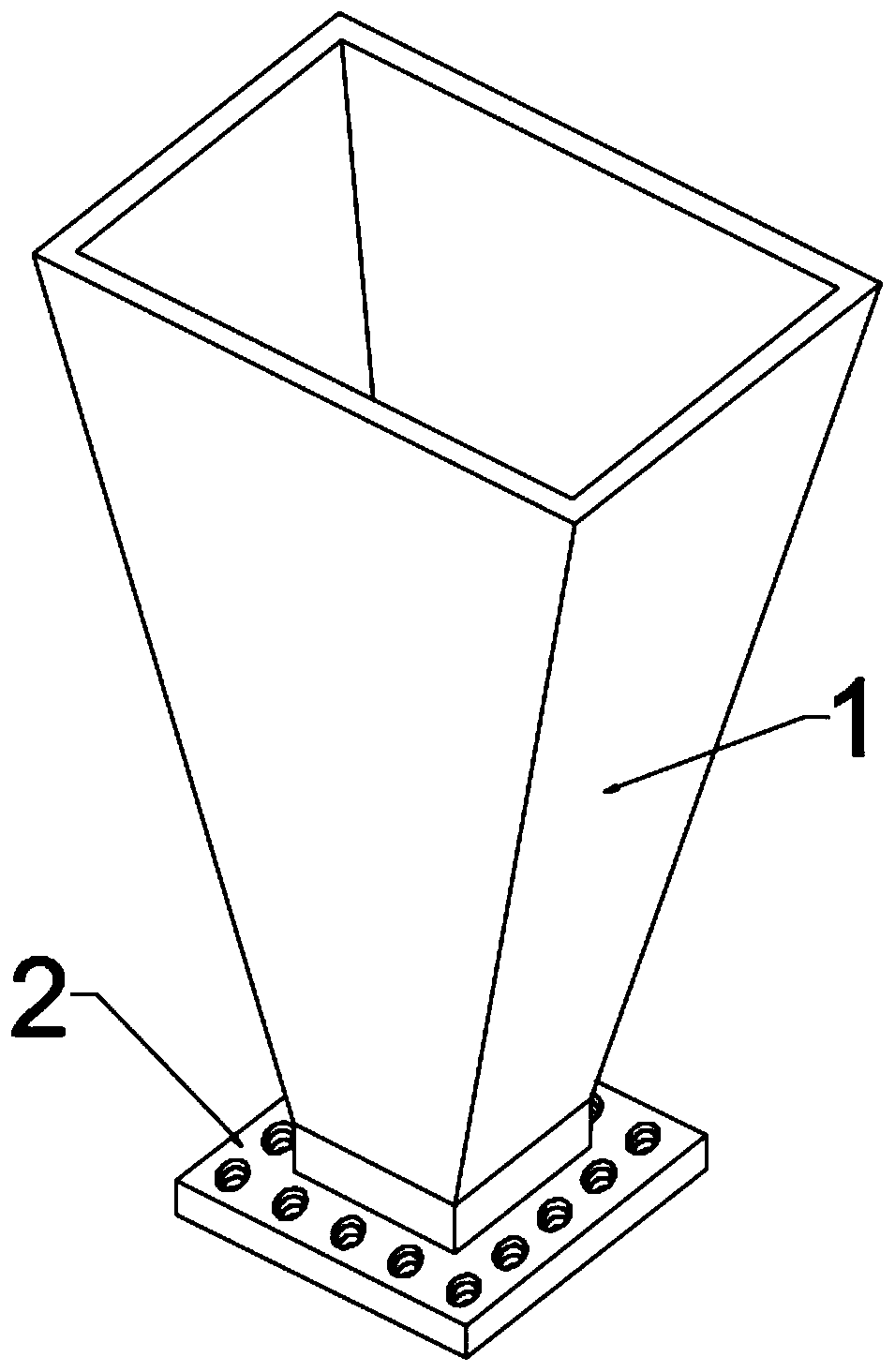

[0022] Specifically, the pre-extrusion assembly includes an auger 4, a motor 5 whose flange is installed on the side of the auger 4 opposite to the hopper 1, a helical roller 6 connected to the output end of the motor 5 and arranged in the auger 4, and a connecting auger 4. The dragon 4 is close to the discharge hopper 7 below the side of the motor 5, wherein a flange 2 is arranged below the hopper 1, and the upper side of the auger 4 relative to the motor 5 is fixed and communicated with a connecting pipe 3, and the upper end of the connecting pipe 3 is connected to the hopper. The flange 2 below 1 is fixedly connected by bolts, and the motor 5 is electrically connected to t...

Embodiment 2

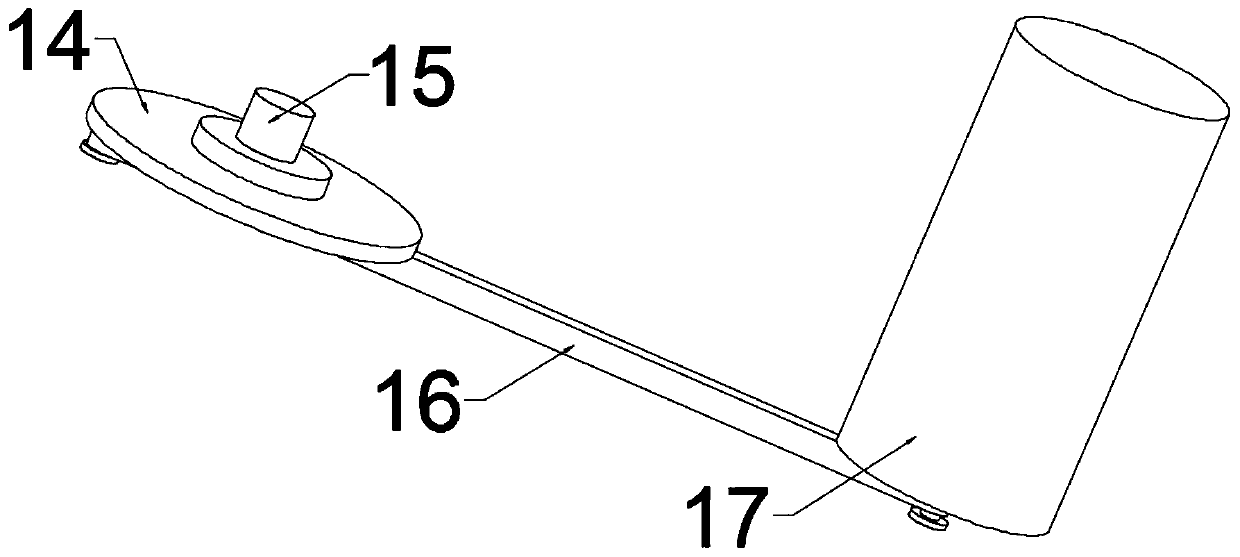

[0025] In order to further explain the above-mentioned feed rolling device with pre-compacting function, in another embodiment of the present invention, a feed rolling device with pre-compacting function, the transmission mechanism includes a fixedly connected helical roller 6. The worm 10 at the end rotates the worm wheel 12 that is arranged above the rolling box 8 and meshes with the worm 10, connects the worm wheel 12 through the transmission member 13 and rotates the rotating shaft 15 that is arranged in the rolling box 8, wherein the end of the worm 10 The lower end of the mounting plate 11 is fixed on the outer wall of the rolling box 8, and the runner 14 is fixed on the rotating shaft 15. It should be noted that a transmission part 13 is provided above the rolling box 8 Through the square hole, the rotating helical roller 6 drives the worm 10 to rotate, the worm 10 drives the worm wheel 12 to rotate, and the worm wheel 12 drives the rotating shaft 15 and the runner 14 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com