Arc extinction device used for live working

A live work and arc suppression technology, applied in the direction of coupling device, connecting device components, circuits, etc., can solve the problems of cumbersome installation of arc suppression function leads, low comprehensive utilization rate of tools, time-consuming and laborious operation, etc., and meet the construction operation standard. Orderly, improve work efficiency, improve the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

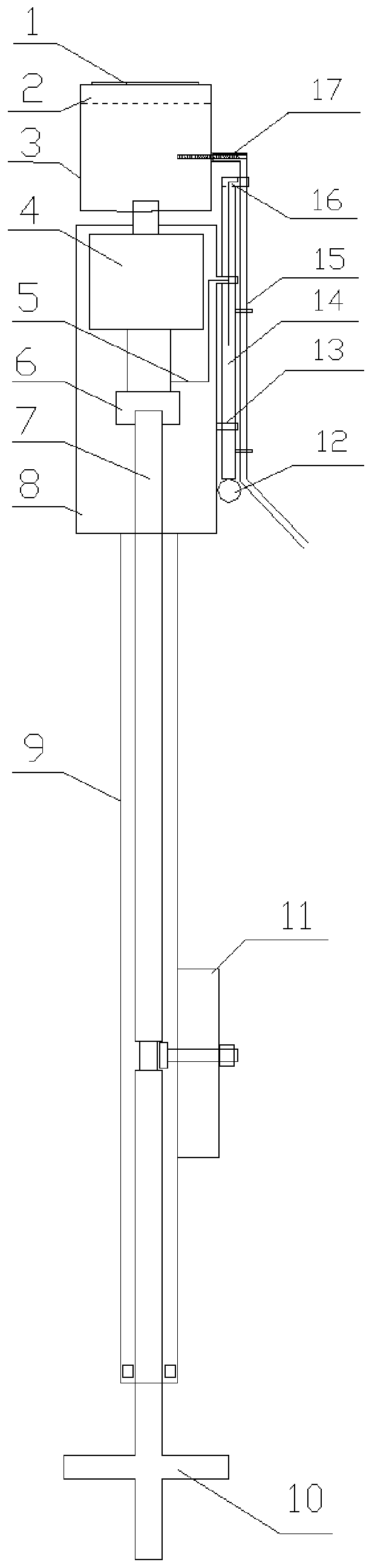

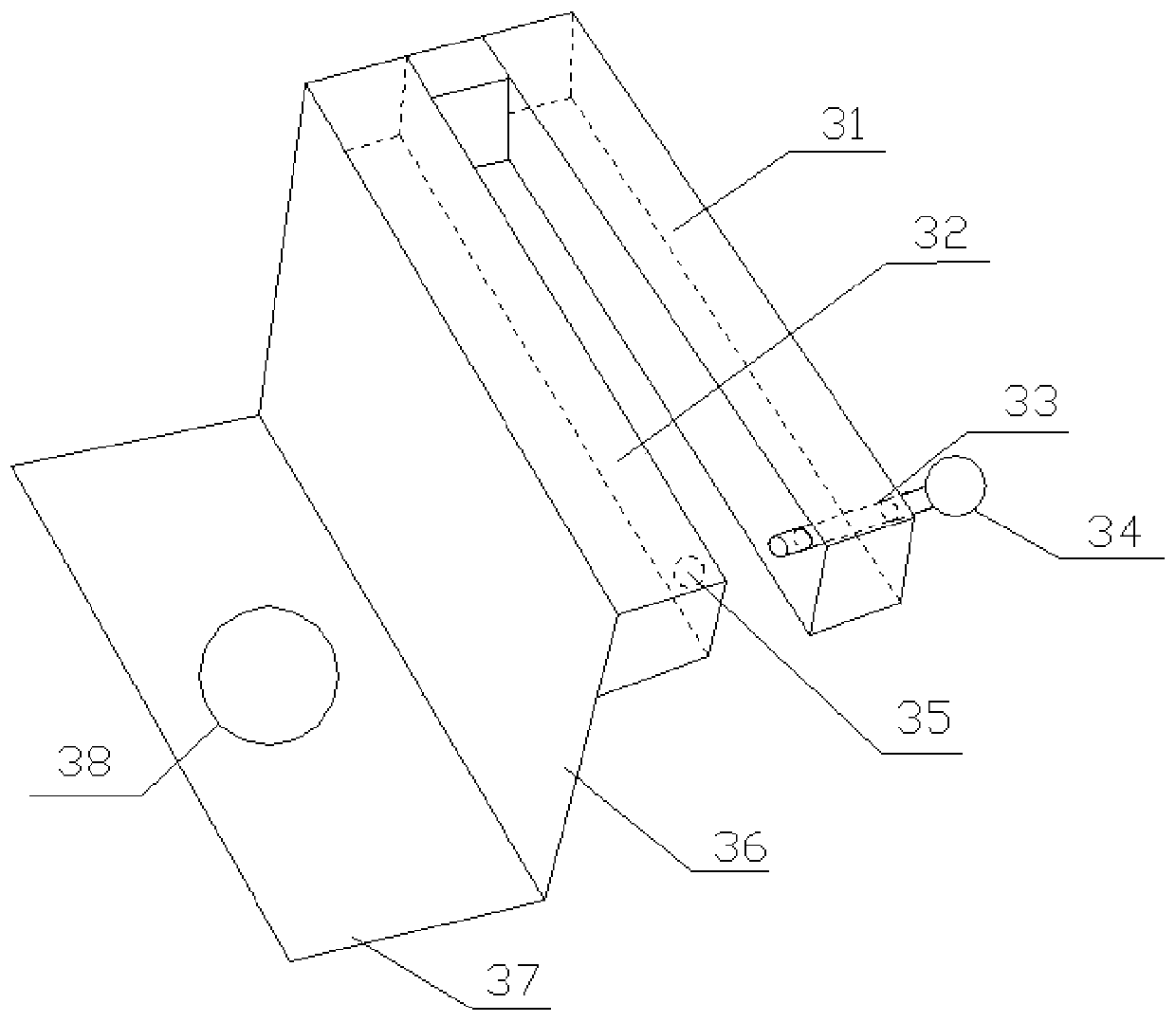

[0024] An arc suppression device for live work, comprising a wire clamp fixture 3 for fixing a wire clamp 1, the wire clamp 1 at least including a main line clamp and a branch line clamp;

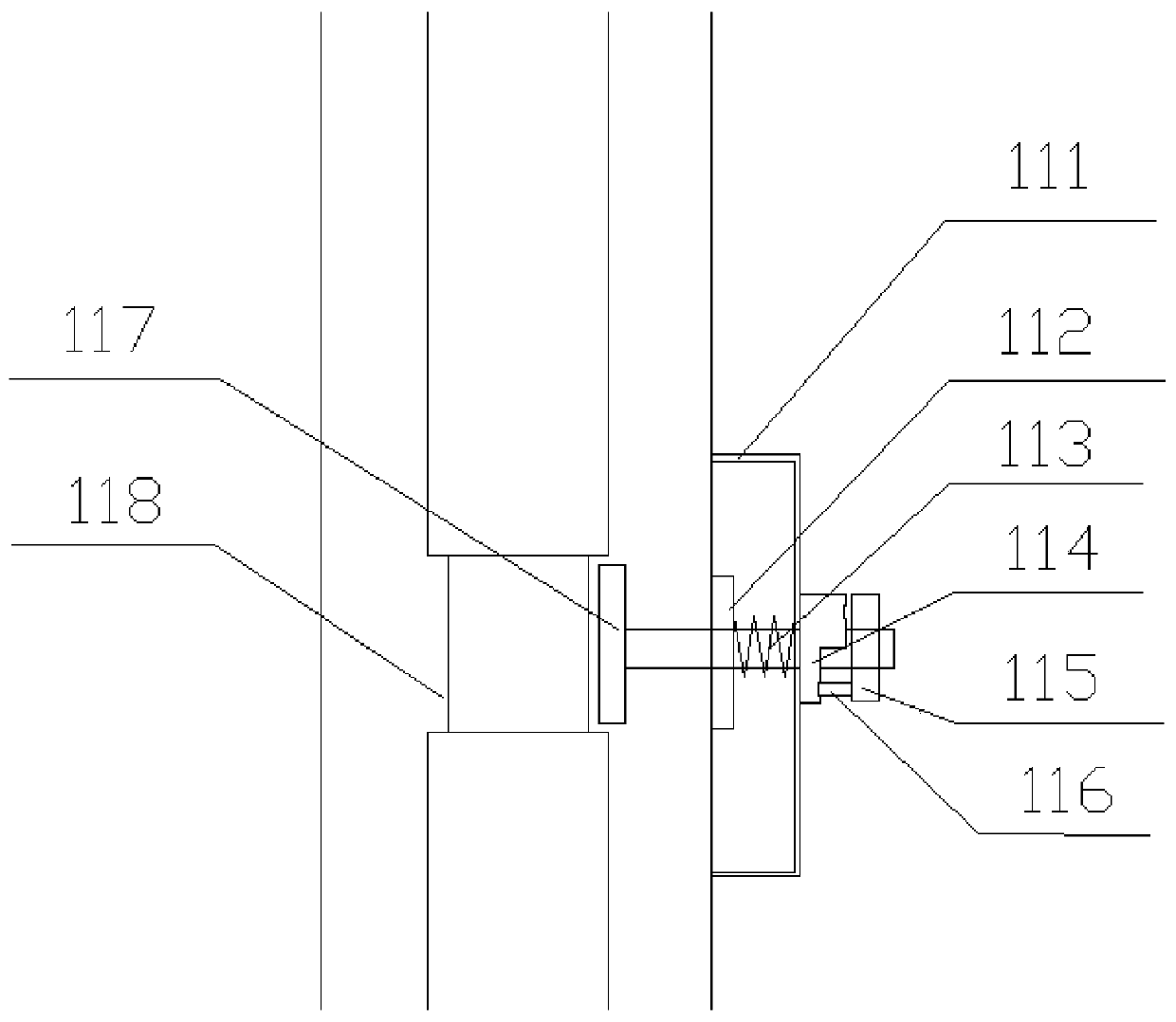

[0025] The vacuum arc suppression switch tube 4 is arranged below the wire clamp fixture 3, the upper end of the vacuum arc suppression switch tube 4 is fixedly connected with the wire clamp fixture 3, and the lower end of the vacuum arc suppression switch tube 4 is connected to a An insulating cylinder 8 is sleeved outside the vacuum arc suppression switch tube 4 and the connector 6, and an insulating rod 9 is sleeved outside the pull rod 7. The top of the insulating rod 9 is fixed to the bottom of the insulating cylinder 8. connection, the side wall of the insulating rod 9 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com