Lamp bead support plate cutting machine

A cutting machine and lamp bead technology, which is applied in metal processing and other directions, can solve the problems of insufficient precision and low cutting efficiency, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

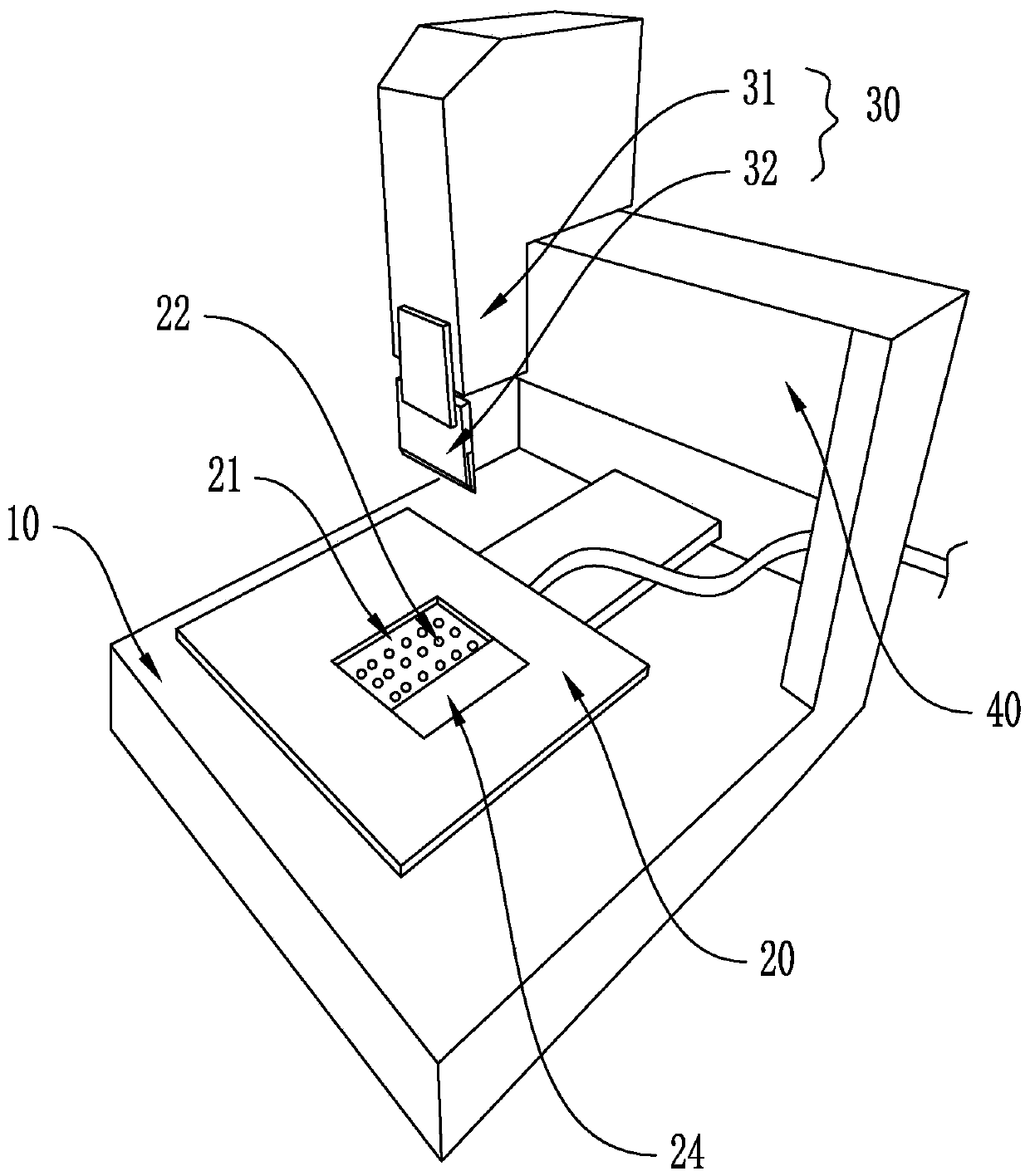

[0020] refer to figure 1 , a LED lamp bead bracket cutting machine of the present invention,

[0021] A LED lamp bead bracket cutting machine, comprising:

[0022] Machine table 10: a jig 20 that can slide on the machine table 10 is provided, and the jig 20 is provided with a groove 21 for placing the lamp bead bracket;

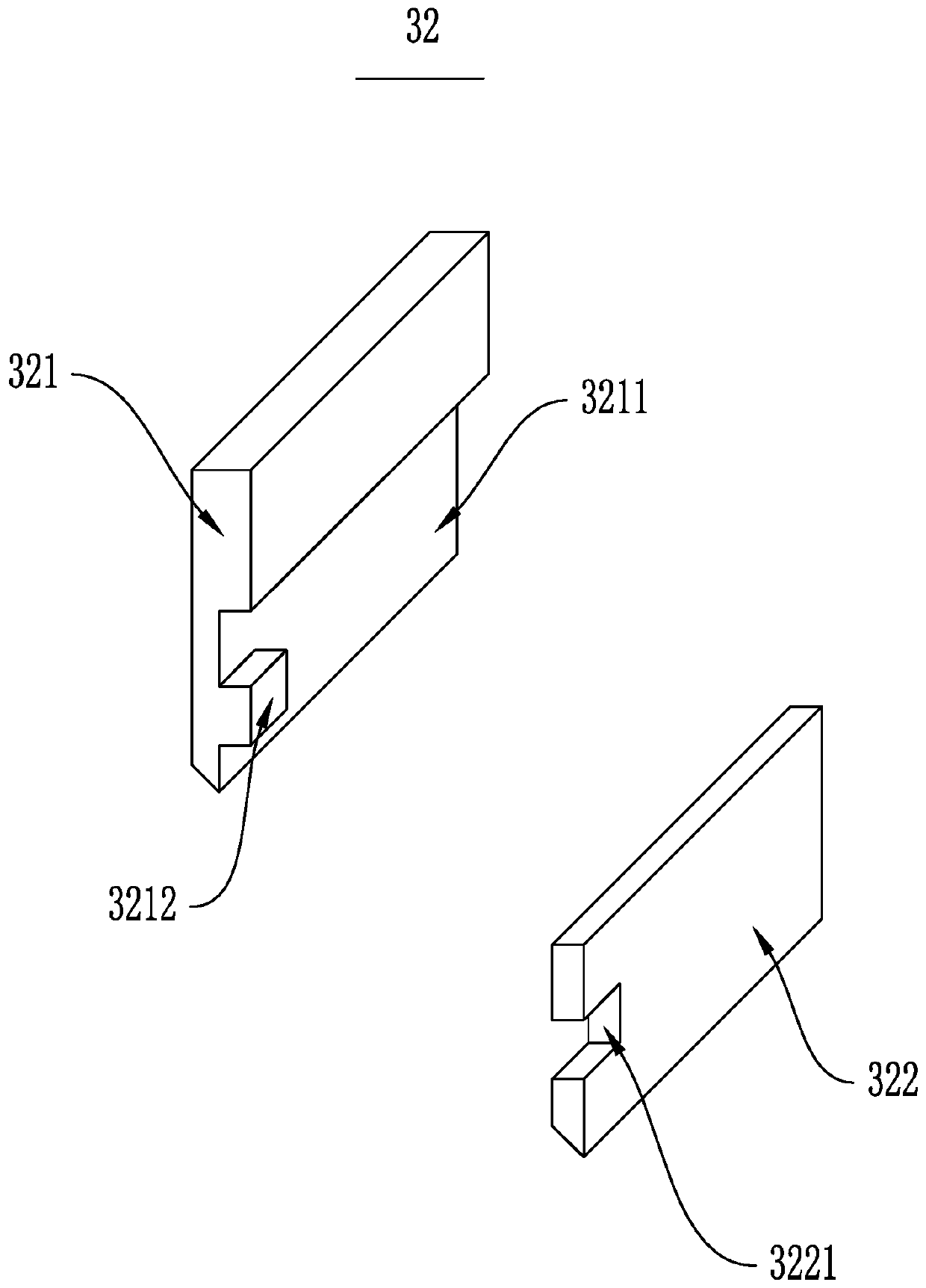

[0023] Cutter 30: It can be lifted up and down and cut the lamp bead bracket in the fixture 20;

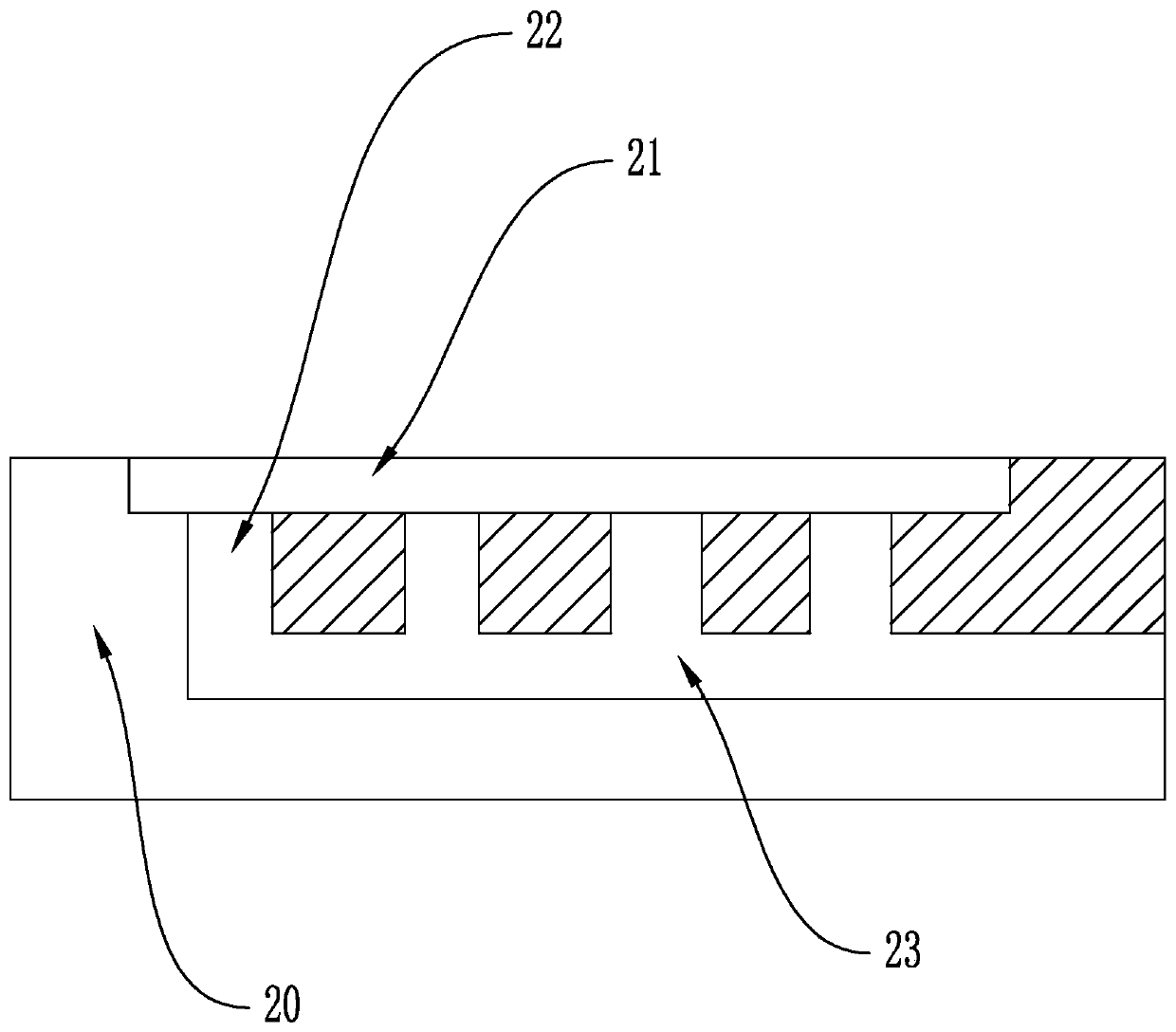

[0024] Among them, refer to image 3 , the clamp 20 is provided with several air intake passages 23, the bottom surface of the groove 21 is provided with several through holes 22, the through holes 22 correspond to the air intake passages 23 one by one, the air intake The channel 23 is connected with an air pressure device.

[0025] In actual use, the fixture 20 is used to fix the lamp bead support plate, and the up and down cutter 30 is used to cut the lamp bead support plate. During the cutting process, the fixture 20 is fed back and forth to complete the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com