A sliding installation method and system for an offshore electrical platform

An installation method and sliding technology, applied in the field of offshore wind power development and marine engineering, can solve the problems of large floating crane transportation barges with large draft, high design cycle, and inability to apply installation, etc., achieving significant engineering economic benefits and widening the selection surface , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further illustrate the content, characteristics and effects of the present invention, an example of an offshore electrical platform with a lower block as a jacket, an upper block of 3,000 tons, and a water depth of about 4 m is listed hereby, and the description is as follows in conjunction with the accompanying drawings:

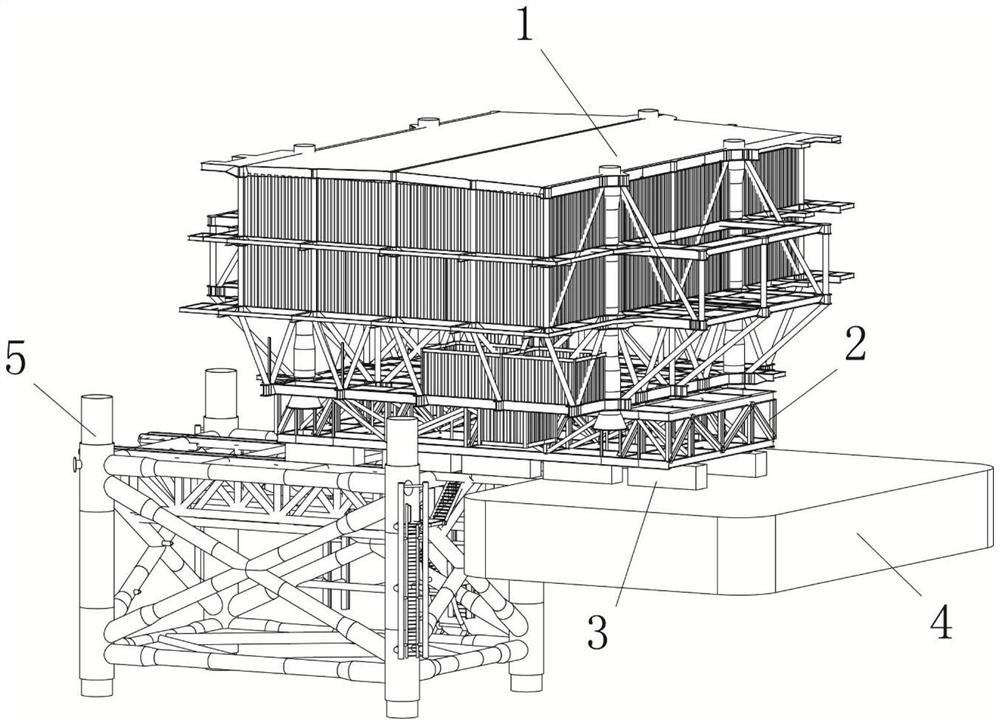

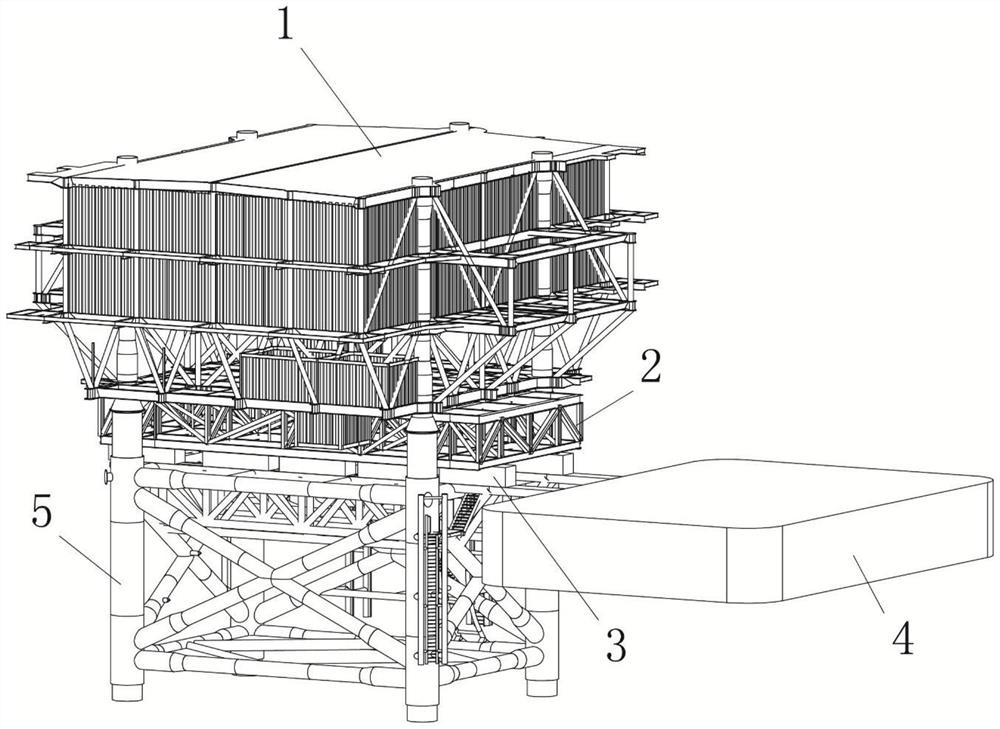

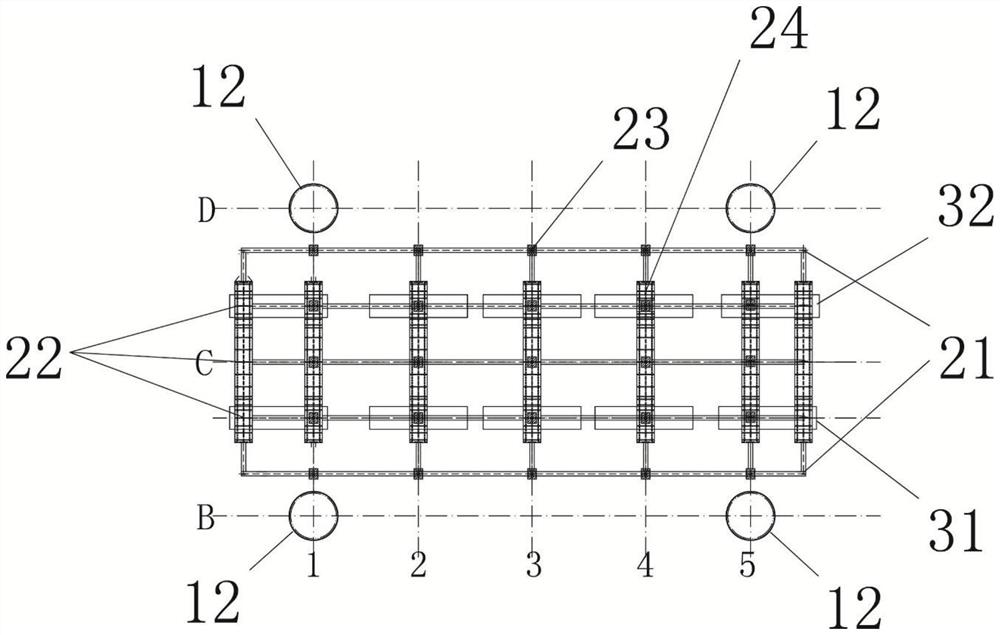

[0045] (1) if Figure 1~2 As shown, this embodiment is composed of the following contents: 1-3000 ton class offshore electrical platform upper block, 2-double-layer support truss, 3-SPMT vehicle group, 4-transport barge, 5-jacket. The upper module 1 is constructed at the dock base, and is temporarily supported by a double-layer support truss 2, and the lower part of the double-layer support truss 2 is supported on the horizontal bracket of the SPMT vehicle group 3. The upper block 1 and the double-layer support truss 2 slide together from the construction site by the SPMT vehicle group 3 to the transport barge 4, and the transport barge 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com