Shape memory alloy-driven online dynamic balance adjustment device

A technology of memory alloy and adjustment device, which is applied in the direction of static/dynamic balance test, measuring device, machine/structural component test, etc. It can solve the problems that offline dynamic balance does not work, industrial realization is difficult, and control is difficult. , to avoid damage to the dynamic balance state of the rotor, to ensure safe and stable operation, and to achieve the effect of simple driving principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

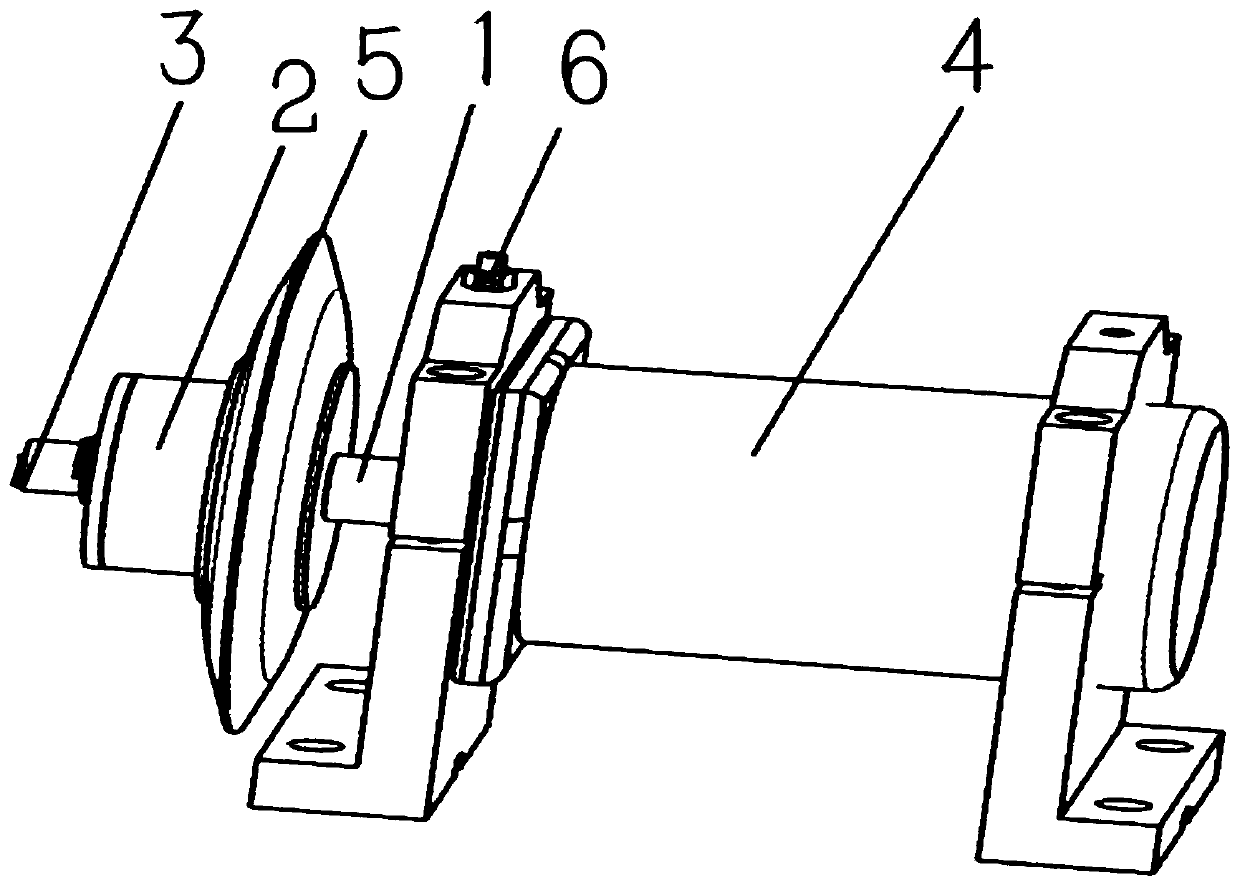

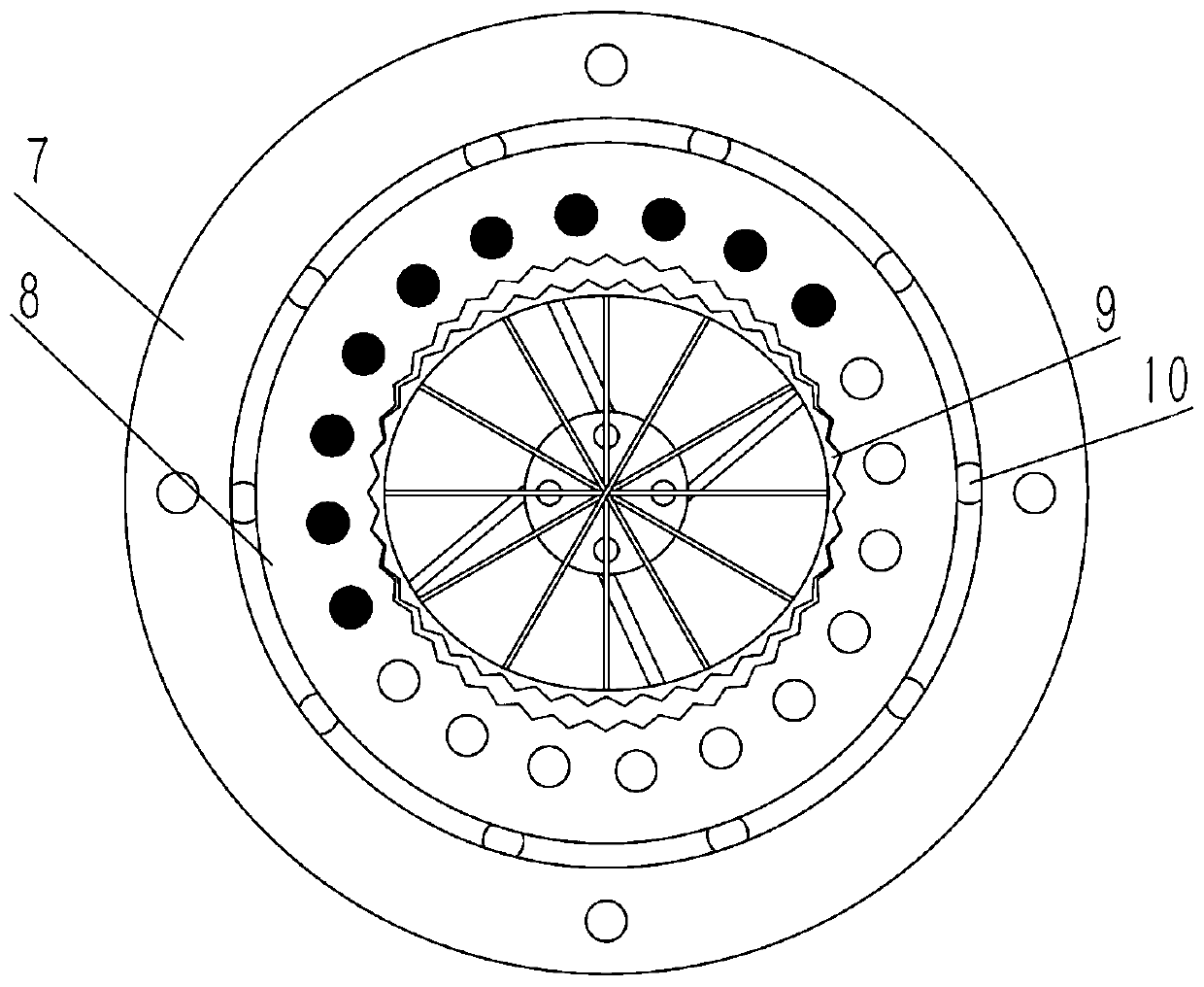

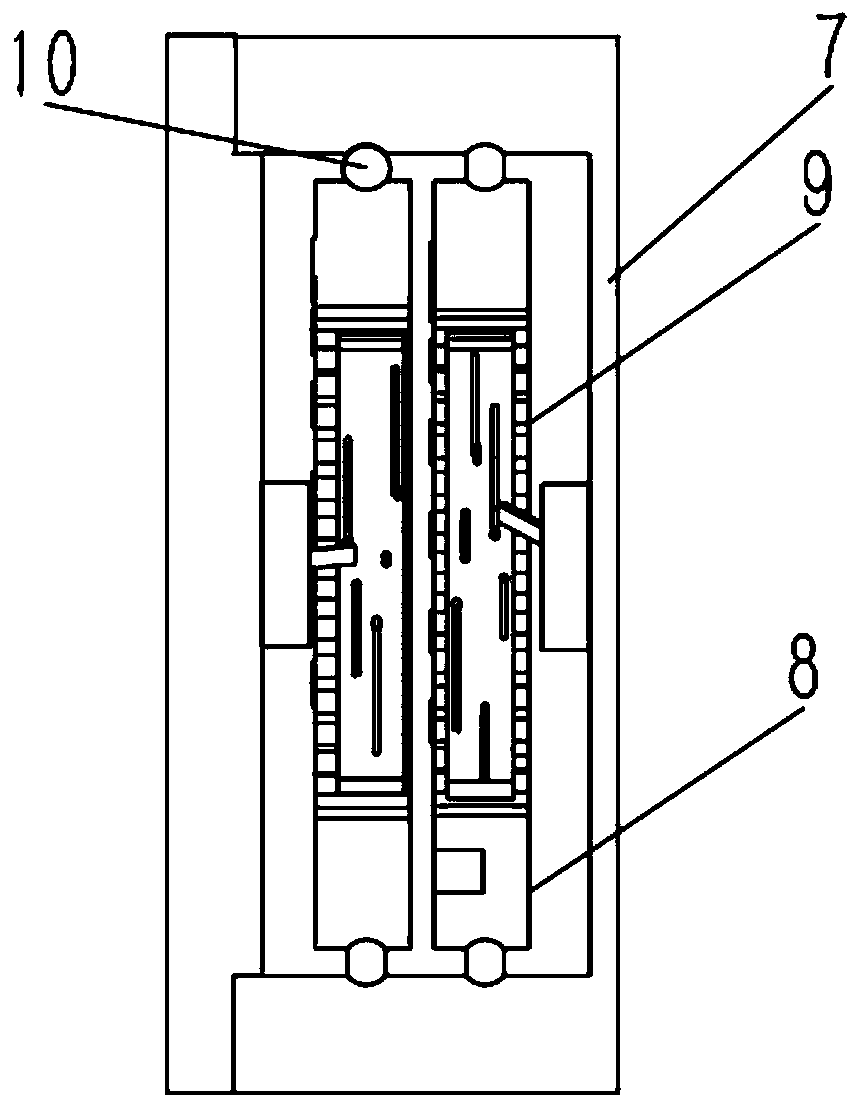

[0034]Embodiment 1: The online dynamic balance adjustment device includes a balance head 2 and a conductive slip ring 3, and a balance object 5 is connected to a fixed shaft on the rotating shaft 1, and the balance head 2 is connected to the balance object 5 shafts, and the conductive slip ring 3 It is connected with the balance head 2 shaft, and the balance head 2 introduces connecting wires through the conductive slip ring 3; the balance head 2 includes a housing 7, two flexible rings 9 and two rigid weight rings with unbalanced weights 8, wherein the flexible ring 9 is a metal elastic body part with a thin-walled annular feature, which is made of alloy structural steel with good strength and fatigue resistance. Specifically, the inner surface of the flexible ring 9 is welded and fixed to the ends of some memory alloy wires 13 passing through the center of rotation of the flexible ring 9; the outer side of each flexible ring 9 is also provided with outer teeth 16 around its c...

Embodiment 2

[0035] Embodiment 2: On the basis of Embodiment 1, the outer walls of the two rigid weight rings 8 of the online dynamic balance adjustment device are provided with a slideway 19, and each slideway 19 is provided with a cage, and each cage There are a plurality of balls 10 inside, and each ball 10 is respectively embedded in the corresponding slideway and between the chute 11 of the matching slideway 19 provided inside the housing 7, and each rigid weight ring 8 and the housing 7 pass through Ball 10 carries out circumferential limit. Specifically, half of the number of counterweight holes 17 in each rigid counterweight ring 8 is provided with counterweights 18 . The memory alloy wire 13 is electrically connected to the conductive slip ring 3 via the end cover lead groove 22 provided on the housing 7; The balancing object 5 is fixedly connected; the conductive slip ring 3 is axially connected to the end face of the housing 7 of the balancing head 2 through bolts. The balance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com